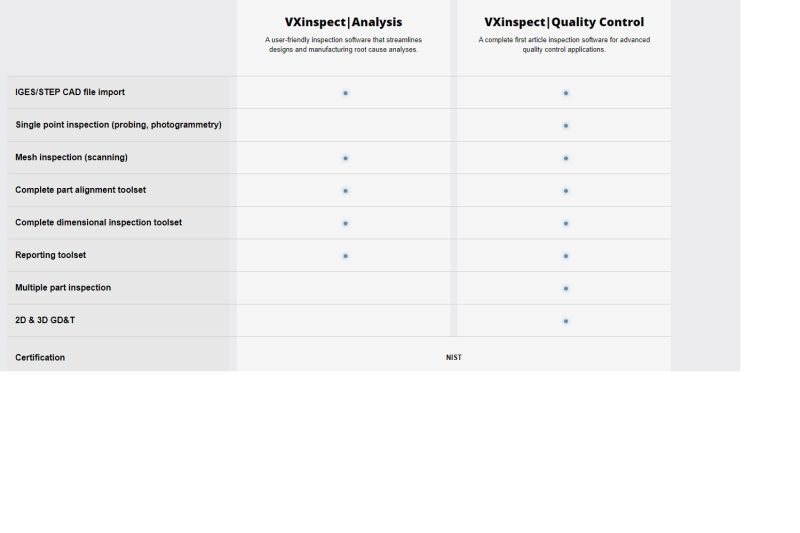

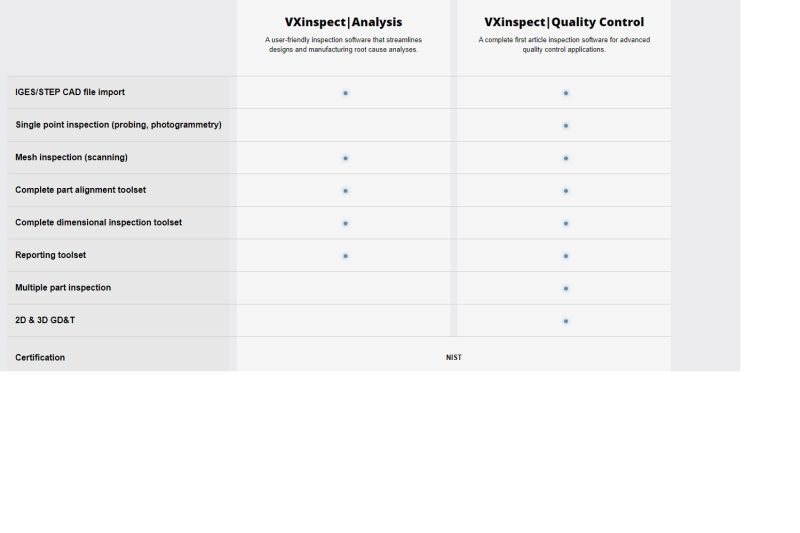

Complete toolset for all inspection workflows, from simple dimensional analyses to extensive inspection programs

VXinspect is a dimensional inspection software that enables quality control and quality assurance professionals to perform inspections and generate reports based on meticulous engineering requirements.

Whether for performing simple dimensional analysis or building an extensive inspection program, VXinspect offers a complete toolset for all inspection workflows, with no compromises on measurement quality or GD&T requirements.

Thousands of users, satisfied with its performance and intuitiveness, have already endorsed VXinspect, considering it the quality inspection software that offers the most value for the money spent.

STEP 1

Measure

VXinspect works in multiple measurement modes by seamlessly integrating photogrammetry, single-point touch probe, and non-contact measurement (scan).

- 3D scanning

- Probing

- Photogrammetry

STEP 2

Import

VXinspect supports CAD import or any mesh for direct measurement comparisons with reference 3D models, leading to a better understanding of manufacturing defects.

STEP 3

Align

As an object’s position and orientation in space are crucial during the inspection, VXinspect includes a complete alignment toolset to fulfill inspection requirements and generate more accurate results.

- Best-Fit

- Feature-based (PLP, Points, etc.)

- Datum

- Reference Point System (RPS)

STEP 4

Analyze

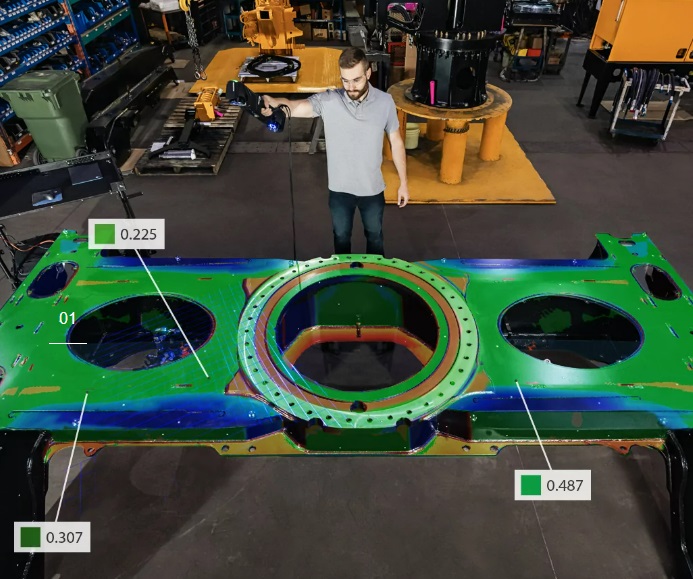

Thanks to its sophisticated algorithms and calculation methods, VXinspect combines simple, yet powerful tools and features to fully analyze the inspected parts.

- Colormap (3D deviation comparison)

- Geometric features

- Cross-sections

- Calipers

- GD&T

STEP 5

Report

VXinspect makes it easy to create and share inspection reports in multiple formats.

- Customizable reports

- Multiple formats (PDF, Excel, XLS, CSV)

STEP 6

Repeat

When a repeat inspection is required, VXinspect can quickly move from one part to the next with minimal steps.

- Multiple part inspection

- Automatic measurement extraction

VXmodel: SCAN-TO-CAD SOFTWARE MODULE

The simplest path from 3D scans to your CAD software or additive manufacturing workflow

From 3D scan to CAD model in a blink

VXmodel is a post-treatment software module designed to optimize meshes and prepare 3D scans for 3D printing. VXmodel also enables designers and engineers to finalize 3D scan data and use it in their reverse engineering and product development workflows.

With a fast processing time that promptly optimizes the mesh and extracts all needed geometrical information, designers and engineers can quickly go back to the CAD workflow they already know.

Satisfied with its performance and complete toolset, thousands of users have already endorsed VXmodel, selecting it as their favorite complement to CAD software

COMPATIBILITY WITH ANY CAD SOFTWARE

With a simple right-click, export your 3D data and complete your design in your prefered CAD platform, without having to learn new software. VXmodel is compatible with any CAD platform using standard formats (.iges, .setp, .dxf). Work in the ecosystem you already know and master.

Enhance your workflow with direct transfer to the following CAD software.

STEP 1

Edit mesh

VXmodel provides simple, yet efficient tools to prepare the 3D scan mesh for reverse engineering or 3D printing.

- Clean mesh

- Fill holes

- Merge meshes

- Decimate mesh

- Make mesh watertight

STEP 2

Align

3D scans must be aligned to the coordinate system before exporting, which is a simple but crucial finalization step. The VXmodel alignment tool is highly flexible and straightforward.

- Entity-based alignment

- Best fit alignment

STEP 3

Extract entities

VXmodel allows you to easily generate NURBS surfaces for characterizing freeform regions. Geometric entities can be easily extracted from the mesh to complete the design in any CAD software.

- Auto surface

- Manual surface

- 2D/3D entities

- Curves

- Cross-sections

STEP 4

Transfer to CAD

With VXmodel, you can easily export 3D data to any CAD platform using standard formats (.iges, .setp, .dxf). With a simple right-click, geometric entities can be transferred directly to the following CAD software:

- SOLIDWORKS

- Autodesk Inventor

- Autodesk Fusion 360

- Solid Edge