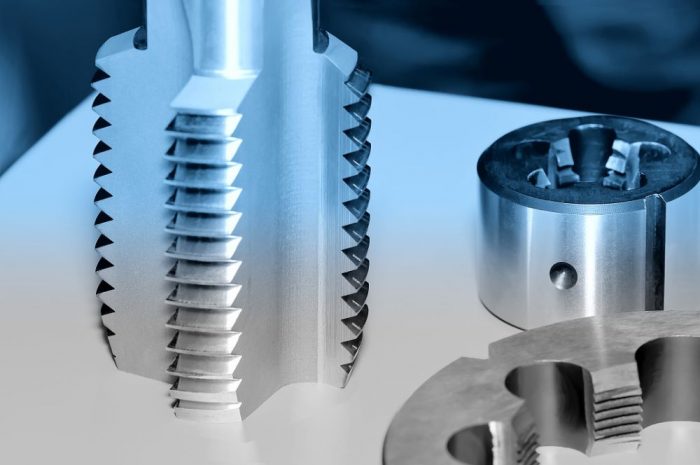

Thread gauges are used for a wide variety of industrial operations and can be considered as equipment that is essential. As an owner of a thread gage, it is important to note that maintenance is necessary in prolonging its lifespan and productivity. However, it is very common for serious mistakes to be made when using this type of gage that can affect the efficiency and condition of the equipment. Ensuring that you avoid these mistakes can help you to prevent any malfunctions of your thread gage. Here at Willrich Precision Instruments, we provide a wide variety of different precision instruments that are made with the finest materials and guaranteed to withstand the test of time.

Exposure to Temperature Extremes when Storing Your Thread Gauges

Obviously, as a precision instrument, the most important thing to maintain in a thread gage is its precision. These gauges are made using metals that can be sensitive to temperature and can either expand or contract depending on the extremes. This change in size of the thread gage can compromise the precision of the thread gage. Thus, you should only store your gauges in a storage area that is not affected by the extreme temperatures as the result of the climate. Additionally, make your best effort to store your gauges in a place where there is as little humidity as possible in order to prevent rust from ruining the quality of its performance.

Allowing Your Thread Gauges to Become Dirty

The dirt that gets trapped in between the parts of your thread gage can negatively affect its functionality and can decrease the precision of the instrument. Therefore, it makes sense to schedule regular cleaning of your thread gage so that proper maintenance of the parts is carried out. Additionally, in the industrial environment, workers’ hands can become contaminated with oil or other substances that can affect the performance of the gauges as well. As such, thread gage operators should be trained to clean their hands before touching the gauges so as to prolong the life and increase the efficiency.

Failing to Lubricate Your Thread Gauges Adequately

Lubricating your thread gage is essential in preventing any corrosion of the parts. This also ensures that the entire system works seamlessly. What you can use for lubricating your thread gage includes oil-based easy-peel wax coatings.

Not Keeping Track of the Accuracy of Your Thread Gauges

It is inevitable and only natural that your gauges become less accurate over time. This would require you to regularly recalibrate the thread gage and document the changes of its accuracy. Ensure that the dates which you carry out the recalibration are documented properly and that the schedule is in line with the recommendations of the manufacturer.

Not Training Your Thread Gage Operators

The easiest way to make sure that your thread gauges are treated and used in the right way is to give your employees who operate the thread gauges proper training. The training should encompass how to use the equipment and also how to engage in proper maintenance so that it can stay efficient for years to come.

Whenever you have new employees, it is always wise to give them proper training as to what the right storage methods and maintenance procedures are. Be sure to hand out manufacturer manuals so that they can learn how to avoid malfunctions and engage in proper safety procedures as well.