Are bottlenecks causing delays in your QC process?

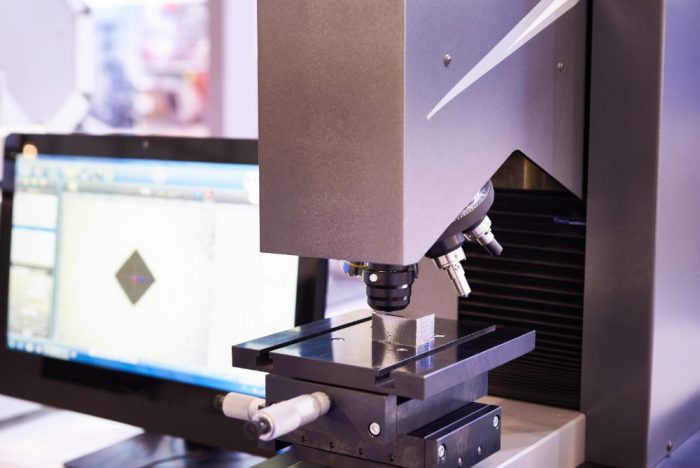

By automating your QC process, you can alleviate bottlenecks and improve efficiency. At Willrich Precision Instrument, a dedicated metrology house with over 51 years of experience, we understand the importance of automation in streamlining your QC process.

Why should you automate your QC process?

Manual gauging is labor-intensive and can significantly slow down production. Additionally, being understaffed or relying on outdated processes and slow equipment like a CMM can further hinder your operations.

Automating manual gauging can help reduce or even eliminate bottlenecks in manufacturing processes. In-process manual gauging can slow down machine cycles and result in idle spindle time, affecting machine output. Automated gauging systems can streamline this process and ensure accurate measurements. In the case of incoming inspection, an automated gauging system can help avoid delays and bottlenecks caused by limited resources and the need for inspection of outsourced parts.

Is automation worth the investment?

It is definitely worth the investment, as it offers numerous benefits that can be quantified with a return on investment (ROI) calculation.

By automating manual gauging processes in manufacturing, companies can experience reduced labor costs, decreased risk, higher levels of quality, and increased capacity. A practical example demonstrates how automation can lead to significant cost savings. For instance, if a medical device manufacturer employs two full-time QC inspectors to measure small parts manually, it costs them $3,360 per week in labor. However, by implementing automation technology, the labor cost for part measurement can be reduced by at least 80%, resulting in savings of $2,688 per week.

With the estimated implementation cost of $125,000, the full payback period for this investment is under a year. Beyond the payback period, the ROI is significant. Over three years, the investment can result in a 300% return, paying for itself three times over.

At Willrich Precision, we offer a wide range of metrology products, from sophisticated scanners to basic measuring tools, ensuring that we have the right solution for your dimensional inspection needs.

Don’t let bottlenecks hold you back. Automate your QC process with Willrich Precision Instrument and experience the benefits of increased efficiency and improved ROI.

Visit our website and explore our comprehensive range of solutions today!