Air gaging is similar to mechanical gaging in several ways, e.g., they are best used in dry, clean, and tight conditions. Although air gages are more reliable and durable than mechanical gages, it does not mean they don’t need scheduled maintenance. This means that air supply vigilance and proper tooling maintenance is required to enhance air gaging accuracy. Below are some tips on air supply and tooling maintenance to help you achieve the best possible results:

Check

for Balance Errors

Balance

error tests are often performed by first rotating the air

tooling to allow the jets to be mounted vertically.

The master is then placed on the plug, and if done correctly, it will rest on

the top jets and note the reading. Remember to lift the master so that it restricts

the lower jet as well. Oftentimes, the two-jet air plugs will automatically

balance themselves (one jet will be closer to the workpiece than the other). If

you notice one of the orifices or jets is worn or damaged, it means that the

test has demonstrated that the gage cannot maintain that balance.

Because

plug gages contact the workpiece across a broad surface area, they tend to be

pretty durable. This, however, does not mean one can ignore the possibility of

poor balance or lack of centralization. It is important to perform these tests

as part of one’s annual gage calibration plan.

Be

Mindful of the Air Supply

The

process of compressing air is known to produce moisture. As compressors also

need to stay constantly lubricated, oil mist is often found in the line as well.

That’s why shop air is significantly difficult to keep dry and clean. When

water mixes with oil, these elements act as an abrasive and can cause premature

part wear over time. With that in mind, avoid letting air continuously run

unless it becomes necessary to do so. This is a good way to prevent mist from

entering the gage and damaging the jets.

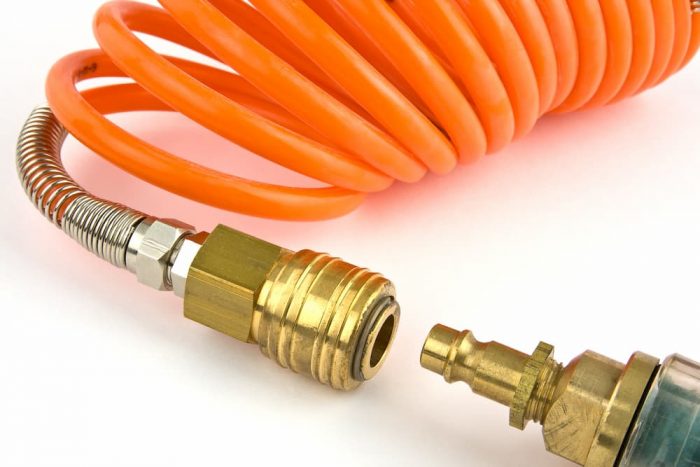

To

keep air supply quality in check, it is recommended that one employs proper air-line

design that intercepts moisture before it enters the meter. Consider pitching

down the air main lines from the source by installing a proper trap on the end;

placing filter in operating gages; bleeding air lines before they are connected

to the gages; and taking air from the top of the mains.

Inspect

for Signs of Wear

Although

air gaging does not involve metal-to-metal contact between the workpiece and

gage component, air gage tooling typically makes contact with the workpiece and

may show signs of wear after repeated use. To inspect for wear, below are some

simple steps to follow:

- Secure the gage with the jets in horizontal

position. - Place a master on the plug, release it, and

take the reading. - Steadily raise the master until it contacts

the plug’s lower surface. - If the readout moves from one chord (through

the maximum diameter) to another, it means that the plug is worn. - If the reading exceeds the part tolerance by

10 percent or more, it means that there is excessive wear.