Electric vehicles (EVs) are taking the automotive industry by storm, with their market share projected to rise from 4% in 2020 to a staggering 18% in 2023, according to the International Energy Agency.

At Willrich Precision Instrument, we understand the impact this trend has on automotive part manufacturers and the need for precise and efficient metrology solutions.

As the demand for EVs grows, traditional internal combustion engine (ICE) part manufacturers must adapt to this new landscape. The transition to EVs brings new challenges to the table, including the development and production of new parts. However, one thing remains constant – the need for impeccable part quality and adherence to strict tolerances.

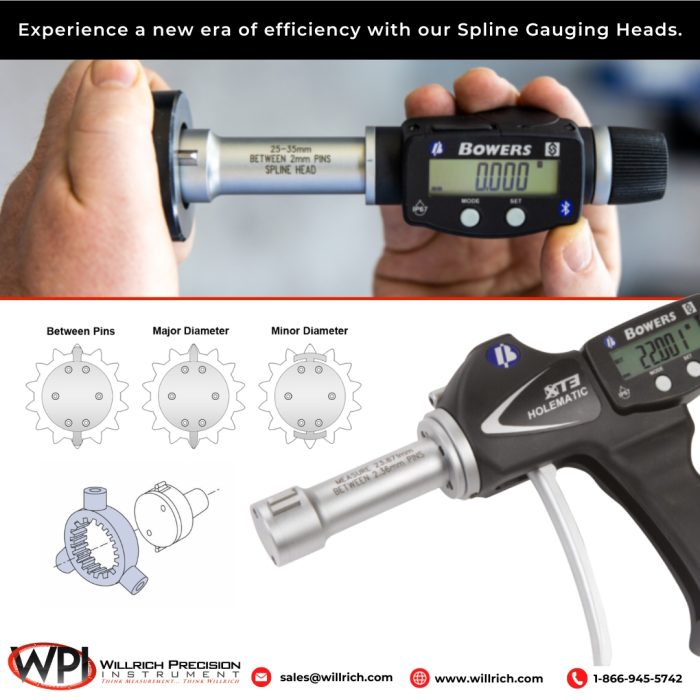

Manufacturers must be equipped to handle these challenges head-on. Measuring reflective materials like aluminum, steel, or composites used in EV parts can be tricky.

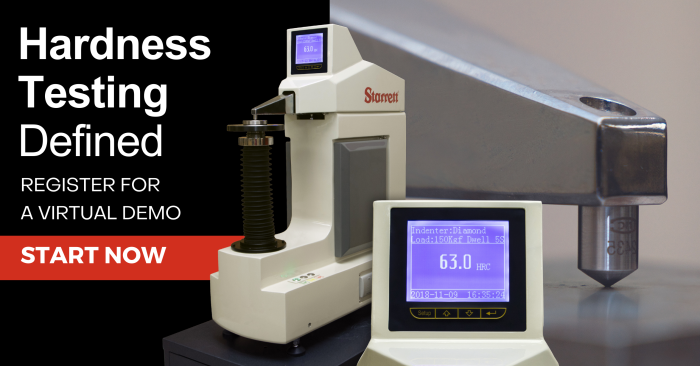

Inspection technologies that rely on white or blue light sensitivity require surface preparation, which adds an extra step to the manufacturing process. This is where our precision metrology instruments come in, ensuring accurate measurements without compromising efficiency.

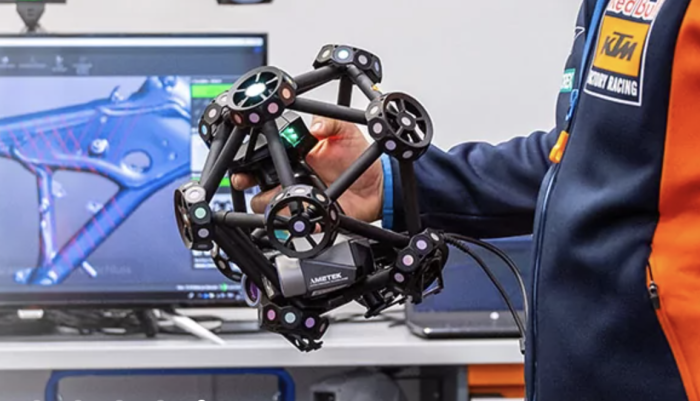

Another obstacle faced by EV part manufacturers is the time-consuming nature of traditional inspection methods. Coordinate measuring machines (CMMs), though reliable, often require programming, setup, and back-and-forth with the production line.

These extra steps can slow down the inspection process, hindering production throughput.

Our innovative solutions enable inspections to be performed directly on the shop floor, reducing time spent on programming and allowing for faster and more efficient inspections.

Furthermore, large and complex parts like the battery tray pose a unique challenge due to their size, weight, and harsh production environments. These factors can make accurate measurements difficult. However, our precision instruments are designed to handle such challenges with ease, ensuring accuracy without compromising on practicality.

At Willrich Precision, we prioritize providing our clients with the most advanced metrology solutions to meet their specific needs. Our instruments offer accuracy, efficiency, and ease of use on the shop floor, allowing EV part manufacturers to maintain impeccable quality control while increasing production throughput.

Dealing with the disruptive shift from ICE to EVs may seem daunting, but with the right metrology partner by your side, you can embrace the booming popularity of electric vehicles and position yourself as a leader in this transformative industry.