Hardness testers are essentially devices that can accurately tell you the hardness of a certain material. This is done by taking into account the effect that an indenter (usually made from hard steel or diamond) has on the surface of the material. The depth of the penetration into the material is measured and from this the hardness can be taken. Here at Willrich Precision Instrument, we understand the difficulties one might face when choosing a hardness tester because of how many different types, brands and models there are in the current market. We specialize in hardness testers and other high-quality metrology instruments that can suit the industrial needs of all our clients.

The Different Kinds of Hardness Testers

In the current market, there are two main types of hardness testers. They can either be bench hardness testers, also known as stationary or classical hardness testers. On the other hand, they can be portable hardness testers, more commonly known as mobile or electronic hardness testers.

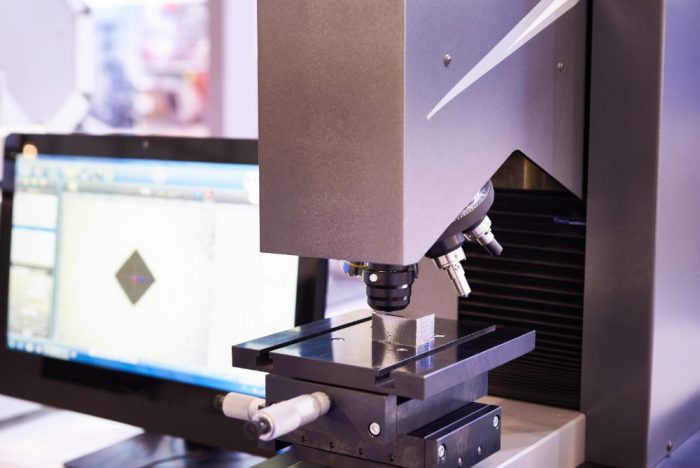

Bench Hardness Testers

As the name suggests, this is a very classic hardness tester that can measure the hardness of materials using traditional methods such as Brinell, Vickery or Rockwell. Usually, when you are looking for a hardness tester that uses the Vickery method for example, it will be called a “Vickery bench hardness tester”. As the word “bench” suggests, there are also some bench top hardness testers in the market that can allow the user to measure the hardness by a few different hardness scales. There are actually some hardness testers that can measure with a combination of scales. All bench top units are big in size and can be very heavy, with some models being over 50 kilograms. They have to be mounted on a table or the floor, which allows for easy measurements using the direct method.

Portable Hardness Testers

In contrast to the bench hardness testers as mentioned above, portable hardness testers are obviously much smaller in size. They are also much lighter in weight. Additionally, being much more compact than bench hardness testers, they can measure the hardness of your materials with some scale violence. There are several advantages to using portable hardness testers. For example, you can bring the device with you easily from home to the workshop to measure the materials that you want to test.

Portable Hardness Measuring Instruments

These are also portable like the testers, but the main difference is that they are electronic devices. What this means is that there is usually a larger range of features that you might not get with an analog device. For example, you will be able to save the results on the device’s internal memory. This would greatly increase the convenience for users because the measurement results can then be transferred to a computer so that reports can be created. The reports can be created using specialized ARM control programs that are more common in portable hardness testers. However, there are very rare cases where some tests can only be carried out by bench hardness testers. In all other cases, portable hardness testers work just fine.