DA-SP-190-W16, DIMENSIONAIR, DA-SPEC-190, 9-0-1, USE W/4O FOOT HOSE, Air Gages, Modified, Code- AV

DA-SP-190-W2, DIMENSIONAIR, DA-SPEC-190 5-0-5 DIAL, USE W/30 FT HOSE

DA-SP-190-W1, DIMENSIONAIR, DA-SPEC-190, 5-0-5,USE W/3 FT HOSE, Air Gages, Modified, Code- AV

Mahr Federal Pump Barrel Air bore gages. DA-SPEC-190 Dimensionair® with a choice of three available ranges:

Dial 5-0-5: Range ±0.127mm ±.005in

Dial 8-0-2: Range+0.200/-0.050mm +.008/-.002in

Dial 9-0-1: Range +0.225/-0.025mm +.009/-.001in.

Most companies that are making these new go with the +.005 to -.005 range where the repair houses go with either +.009 to -.001 or +.008 to -.002.

Download the DA-SPEC-190 Mahr Federal Dimensionair air plugs by using the link below:

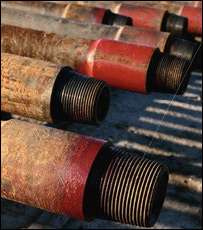

Specialty Oil Pump Barrel Air Gages

The barrel air plugs are typically used with a 30ft long hose. AHO-SPEC-102 is a rubber hose and AHO-SPEC-175 is a heavy duty hydraulic hose. The bore is explored over its full length

Extended Range Air Plugs and Oil Industry Air Gages are high-precision measurement tools designed for inspecting bore sizes and wear in applications like oilwell subsurface pump barrels. These tools offer accurate measurements within a ±0.005in range. This makes them ideal for monitoring bore wear and achieving the correct dimensions in large, long bores.

These air gages utilize air flow through nozzles to measure the dimensions of a bore. As air flows between the nozzle and the bore’s surface, the change in air pressure is used to calculate the size of the bore. This non-contact method prevents damage to the part while providing highly accurate readings.

Primarily, these tools are used in the oil and gas industry to monitor subsurface pump barrels and related equipment. They are also valuable in other sectors requiring precise bore measurements, including aerospace and heavy manufacturing.

Extended Range Air Plugs are specifically designed for the oil industry, particularly for measuring pump barrels in oilwell equipment. These gages can handle large bores and measure wear patterns that are common in oilwell environments. The gages are built with extra clearance and durable, chrome-plated surfaces, extending their life in tough conditions.

Mahr Federal Pump Barrel Air Gages are equipped with features like extra clearance, a 1/4in polished radius edge, and hard chrome plating to extend their lifespan. These tools can measure long bores with a total range of up to 0.254mm/0.010in. They provide accurate size readings while monitoring wear over time.

These air gages offer exceptional accuracy, typically within ±0.005in. With multiple range options, including +0.009/-0.001in and +0.008/-0.002in, users can choose the precision level that suits their specific application.

Yes, while these gages are designed for the oil industry, their high precision and durability make them suitable for other industries requiring accurate measurements of large, long bores. They can be used in aerospace, automotive, and heavy manufacturing sectors for various measurement tasks.

The DPS model number refers to the specific design of the air gage system, such as the 2500:1 tooling with extended clearance and chrome plating. This model means the air gage can measure the full range of dimensions required for oilwell gaging and other heavy-duty applications.

Choosing the correct range depends on the specific requirements of your application. The available ranges include the Dial 5-0-5 with a range of ±0.127mm/±0.005in, Dial 8-0-2 with a range of +0.200/-0.050mm/+0.008/-0.002in, and Dial 9-0-1 with a range of +0.225/-0.025mm/+0.009/-0.001in.

Each range is suited to different types of measurements. For this reason, consult with an expert at Willrich to find the best fit for your needs.

For detailed information, technical support, or to place an order, contact Willrich Precision Instrument. You can reach us at 866-945-5742 or email us at [email protected]. Our team is available to guide you through the selection process and provide any assistance you need.

For precise, reliable measurement solutions in the oil industry and beyond, contact Willrich Precision Instrument today.