Leitech Combi Thread Depth Gage

Leitech is a thread control system for internal threads, which measures the internal thread size and depth in one operation.

This instrument is the only thread gauge of its kind in the world that measures the thread size and depth in one operation. This gives the user an accurate and reliable measurement, and at the same time provides timesaving of up to 70%, compared to traditional thread gauges.

Call or email for pricing: Ph: 866-945-5742 / email: [email protected]

-or-

Fill out below Quick Quote Form for sizes needed.

Read More

Leitech Combi Thread Depth Gage Features:

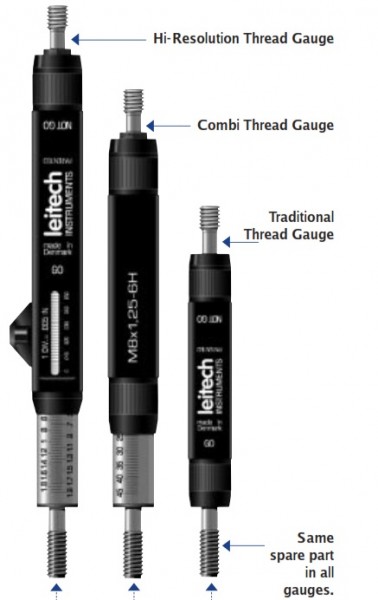

The Combi Thread Gauge:

To control the thread tolerance, the Leitech Combi Thread Gauge is used in the same way as any normal double-ended thread gauge. As the GO side is inserted into

the thread hole, the telescoping measuring sleeve retreats into the aluminum body, providing the user with an accurate depth reading of 0.5mm or .025" resolution per division.

The NOT GO side is used in a conventional manner.

The Hi-resolution Thread Gauge:

Is used in the same way as the Combi Gauge, but with 0.1mm or .005 resolution per division for depth. Also equipped with a locking device that allows the measuring sleeve to be locked

at the depth reading, or at a preset depth. The placement of the thread hole to be measured is not always directly visible to the controller and the reading of the scale is therefor difficult.

The locking device on the Hi-res Thread Gauge makes it possible to read the scale after the measurement been taken

Chrome Doubles the wear life of steel

Dlc Ta-c Wears about 10X longer that standard steel.

DLC (Diamond Like Carbon)

ta-C (amorphous tetrahedral carbon)

DLC coatings significantly reduce friction losses, wear and seizure risks, regardless of the lubricant characteristics.

This makes it possible to keep up with the latest and most severe technical developments whilst preserving the exclusive properties of DLC ta-C.

The value of Diamond-like carbon (DLC) coating accrues from its ability to provide some of the properties of diamond to surfaces of almost any material. The primary desirable quality is hardness, wear resistance, and slickness (DLC film friction coefficient against polished steel ranges from 0.05 to 0.20.

DLC exists in seven different forms. All seven contain significant amounts of sp3 hybridized carbon atoms. The reason that there are different types is that even diamond can be found in two crystalline polytypes. The more common one has its carbon atoms arranged in a cubic lattice, while the less common one, lonsdaleite, has a hexagonal lattice. By mixing these polytypes in various ways at the nanoscale level of structure, DLC coatings can be made that at the same time are amorphous, flexible, and yet purely sp3 bonded “diamond”. The hardest, strongest, and slickest is such a mixture, known as tetrahedral amorphous carbon (ta-C) can be considered to be the “pure” form of DLC, since it consists only of sp3 bonded carbon atoms.

+ + + + + + + + + + + + + + + + + + +