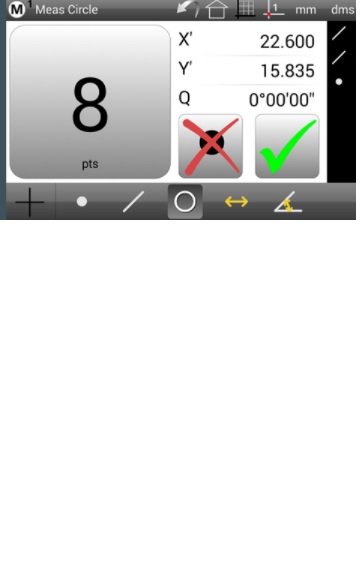

M1 Optical Comparator readout

Read More

Clean, Intuitive Design

The user interface design of the M1 software means you’ll spend more time measuring and less time reading manuals. By combining a familiar user experience with current touch screen conventions, the M1 software can quickly be integrated into your process

and accessible to a wide range of users.

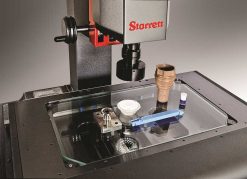

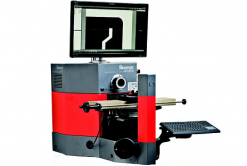

Support for Optical Edge or Crosshair Measuring Systems

Gain access to many of the same powerful features, and intuitive measuring environments, whether using an optical edge equipped system or an externally generated crosshair device. Precise optical edge detection algo-rithms provide accurate results as

well as access to powerful, industry first, measurement functionality.

Advanced Crosshair Probe Toolbox

For Optical Edge enabled systems, both “simple” and “auto edge” cross-hair probes are available. The “auto edge” probe captures points on edges automatically upon crossing. The M1 EdgeLogic™ system (Optical Edge enabled systems only) enables gesture driven

control of start and end measurement commands. Start and finish measurements quickly, without the need for direct software interaction.

Flexible Measurement References

Measurement references are easy to define and flexible enough for a broad range of measurement applications. Simple feature measurements can be made in a snap by merely zeroing or presetting the current stage position as a measurement reference. More

demanding measurement applications are still made easy by zeroing or presetting one or two existing feature locations as independent measurement references.

Popular Feature Constructions Supported

Generate popular construction types, like distances and tangent lines. Constructions with multiple sub-types can be toggled quickly with the change feature type command.

Supported construction types include:

- Average

- Intersections

- Bolt Circle

- Farthest Distance

- Perpendicular/Parallel Line(s)

- Mid/Center Point(s)

- Shortest Distance

- Angle Compliments

- Gage Circle(s)

- End Points

- Tangent Line(s)

Feature Detail Views

Scroll through your measured features list to show individual feature detail views. Feature detail views display important information including feature type (probed, constructed or created), position, dimension, a graphic of probed point distribution,

the number of points probed and form error.

Nominal Values and Deviations

Nominal position and dimension values can be entered for features in the list of measured features and deviations will be calculated based on measured values. Actual (A) values are compared to nominal (N) values and resulting deviations (?) are shown.

True position errors are also shown for some feature types.

Reports

Report contents can include report title, time and date stamps, and all feature measurement result data. Reports can be printed as hard copies to standard Windows compatible printers, or exported as PDF or CSV data files.

Export choices include:

- Windows printer

- Save as PDF file

- Google Drive account

- Email account

- Gmail account

- RS232 device (RS232 enabled systems only)

Machine Integration

Ask your MetLogix representative about the wide variety of encoder interface technologies and other hardware supported by the M1 system.

Support for All Current Industry Standard Software Stage Calibration Methodologies

Robust and reliable machine calibration can be achieved using popular machine correction methods including Linear Error Correction(LEC), Segmented Linear Correction(SLEC) and squareness correction.

Industry Standard Tablet Operating System

With the Android® 4.4.2 or later tablet operating system you gain the performance and reliability of a globally recognized software solution as part of your measuring machine package.