| Initial Test Force: | <29.42, 98.07 N / 10, 3 kgf |

|---|---|

| Test Methods: | Rockwell, Superficial and Light Force Brinell |

| Brinell Force Range: | 61.29, 98.07, 153.2, 245.2, 294.2, 306.5, 612.9, 980.7, 1226, 1839 N / 10, 100, 125, 15.625, 187.5, 25, 30, 31.25, 6.25, 62.5 kgf |

| Rockwell Force Range: | 588.4, 980.7, 1471 N / 60, 100, 150 kgf |

| Superficial Force Range: | 147.1, 294.2, 441.3 N / 15, 30, 45 kgf |

| Test Force Control: | Automatic |

| Table Up/Down Mechanism: | Manual |

| Control Unit: | Color Touch-Panel |

| Test Force Switching: | Operated with Display Unit |

| Test Force Hold Time: | 1 – 120 sec |

| Max Sample Depth: | 5.9″ / 150mm |

| Inside Diameter of Tube: | .87, 1.38″ / 22, 35mm |

| Max Table Loading: | 45lbs / 20kg |

| Ball Indenter: | Tungsten Carbide Ball |

| Display: | Color LCD Touch Screen |

| Language: | Japanese, English, German, French, Italian, Spanish, Korean, Simplified Chinese, Turkish, Portuguese, Hungarian, Polish, Dutch and Czech |

| Data output: | RS-232C, SPC, USB2.0 |

| Power Supply: | AC120V |

| Standard Accessories: | 1/16″ Carbide Ball Indenter, 2x HRC, HRBW, HR30TW, HR30N Test blocks, 40mm V Anvil, 64mm Flat Anvil, Accessory case, Inspection certificate, Instruction maual, Machine cover, Rockwell/Superficial Diamond Indenter, Warranty |

| Rockwell Hardness Scales: | HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRHW, HRKW, HRLW, HRMW, HRPW, HRRW, HRSW, HRVW |

| Superficial Scales: | HR15N, HR15TW, HR15WW, HR15XW, HR15YW, HR30N, HR30TW, HR30WW, HR30XW, HR30YW, HR45N, HR45TW, HR45WW, HR45XW, HR45YW |

| Order No.: | Model: | Max Sample Height: | Main Unit Dimensions: | Touch-Panel External Dimensions: | Mass: |

|---|

| 810-237 | HR-530 | 9.8″ / 250mm | 9.84×26.38×23.82″ / 250x667x621mm | 191x147x71mm | 60kg |

| 810-337 | HR-530L | 15.5″ / 395mm | 11.8×26.2×30.1″ / 300x667x766mm | 191x147x71mm |

Order No. 810-237Model HR-530

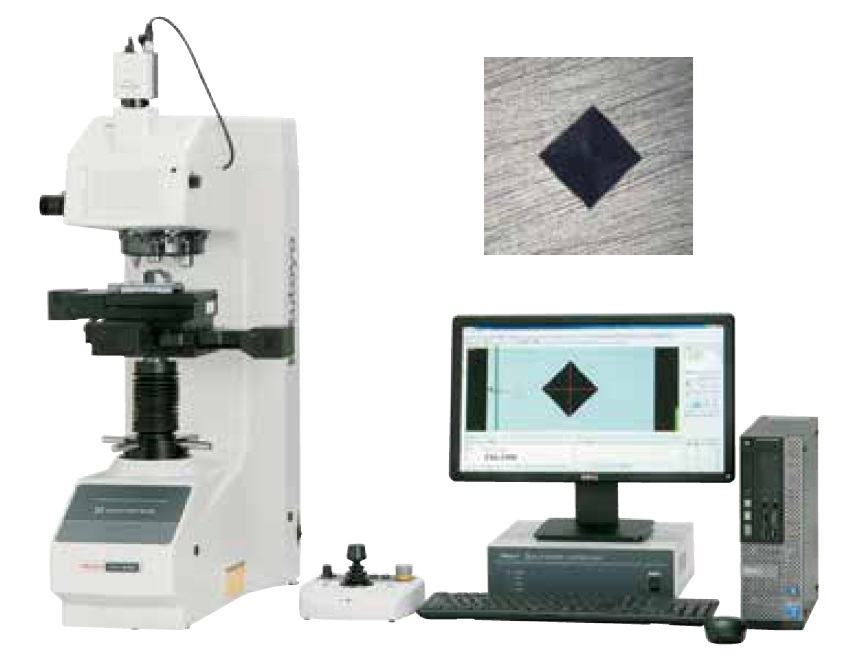

Hardness testing methods: Rockwell/Rockwell Superficial/Brinell/Plastics hardness

Initial test force (N) 29.42N (3kgf), 98.07N (10kgf)

Test force(N)

Rockwell Superficial 147.1N (15kgf), 294.2N (30kgf), 441.3N (45kgf)

Rockwell 588.4N (60kgf), 980.7N (100kgf), 1471N (150kgf)

Light Force Brinell 61.29 (6.25kgf), 98.07 (10kgf), 153.2 (15.6 25kgf), 245.2 (25kgf), 294.2 (30kgf), 306.5 (31.25kgf),612.9 (62.5kgf), 980.7 (100kgf), 1226 (125kgf), 1839 (187.5kgf)

Test force control Automatic (load/hold/unload)

Table up/down mechanism Manual (automatic braking and load sequencing)

Test force switching Operated with the display unit

Test force hold time 1 to 120s (Selectable in units of 1s)

Maximum specimen siz e Height: 9.8″ (250 mm)Depth: 5.9 (150 mm)

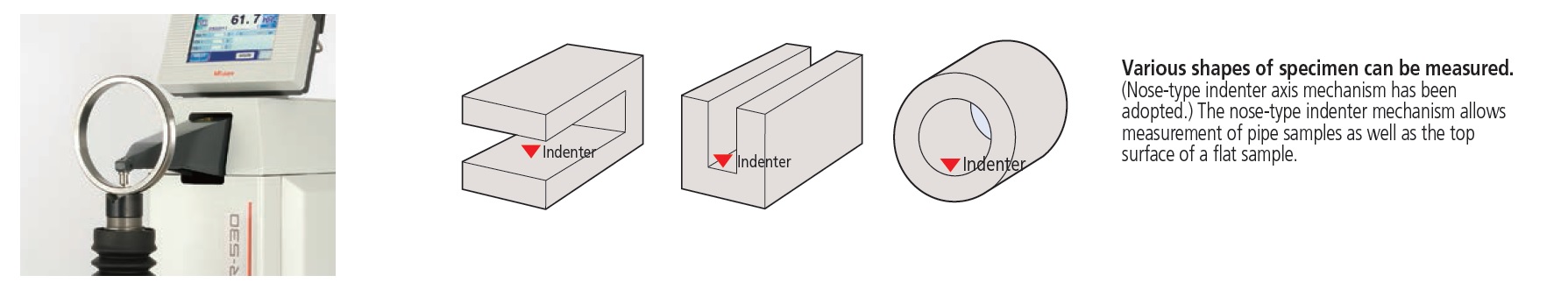

Permissible inside diameter of a tube specimen Minimum hole diameter: 1.38″ (35 mm) (when using the special indenter: .87″ (22 mm))

Display Hardness value, test condition, go/no-go judgment result, statistical calculation result,

X-R control chart, hardness conversion value

Conversion function [HV, HK, HR (Rockwell hardness A, B, C, D, F, G / Rockwell Superficial

15T, 30T, 45T, 15N, 30N, 45N), HS, HB, tensile strength]

Go/no-go judgment function

Continuous test function (for specimens with the same thickness)

Cylindrical correction, spherical correction, offset correction, multi-point correction functions

Statistical calculation function (maximum value, minimum value, mean value, standard deviation,

upper limit value, lower limit value, go count, range, no-go count)

Graph generation function (X-R control chart)

External data output RS-232C, digimatic, USB2.0

External dimensions

Main unit 9.84 x 26.38 x 23.82 (250(W)×667(D)×621(H) mm) 11.8 x 26.2 x 30.1 (300(W)×667(D)×766(H) mm)

Touch-panel display 191(W)×147(D)×71(H) mm

Mass Approx. 60 kg