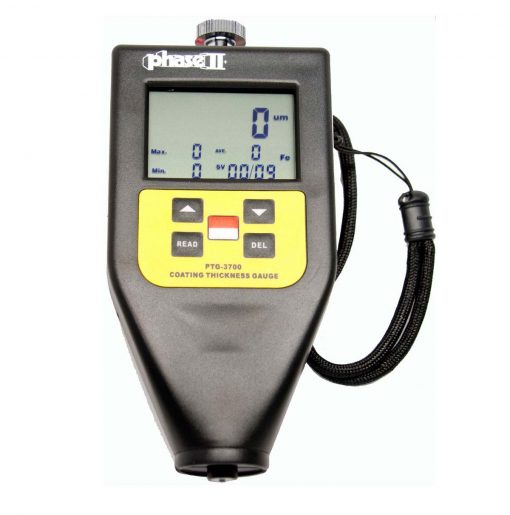

The NEW! Phase II PTG-3700 coating thickness gauge/paint thickness gauge is the latest, state-of-the-art thickness gauge in which you can easily detect the thickness of non-magnetic coatings on magnetic(ferrous) substrates or an insulating coating on a non-magnetic conductive substrate(non-ferrous). The PTG-3700 coating thickness gauge utilizes an integrated auto-detect probe, while the PTG-3750 coating thickness gauges uses an external probe. The auto detect probes on these coating thickness gauges/paint thickness gauges use both eddy current and magnetic induction technologies. The PTG-3700 series coating thickness gauges/paint thickness gauges are full featured w giant screen, backlighting, wider measuring range, advanced memory, browsing and statistics, such as min/max values, averaging and counters. The PTG-3700 coating thickness gauges/paint thickness gauges can be used in many areas of industry including mfg, general engineering, commercial inspection and automotive apps.

NIST Certificate

Phase II PTG-3700 Coating Thickness Gauge Features:

- The PTG-3700 coating thickness gauges utilize an integrated probe that can automatically detect a Ferrous or Non-Ferrous substrate and comes with 2 substrate samples (steel,aluminum), 4 calibrated thickness samples, carry case, batteries and operation manual.