Click below to enlarge Phase II Ultrasonic portable hardness tester PHT-6000

Phase II Ultrasonic Portable Hardness Tester PHT-6000

$5,644.17 – $9,934.26

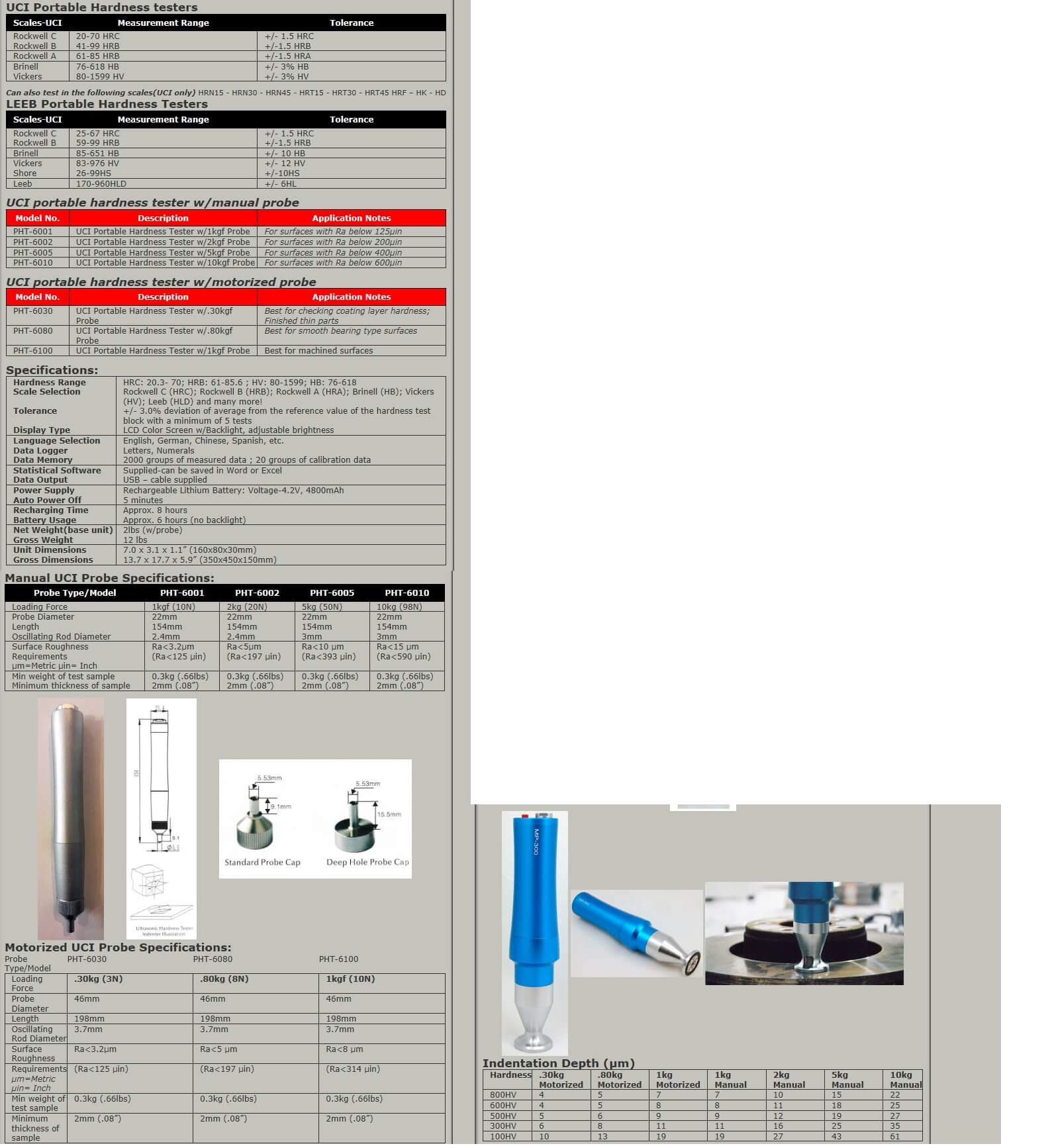

Phase II Ultrasonic Portable Hardness Tester PHT-6000 Series

PHT-6001 w/1kgf Probe

PHT-6002 w/2kgf Probe

PHT-6005 w/5kgf Probe

PHT-6010 w/10kgf Probe

Read More

Phase II Ultrasonic Portable Hardness Tester

PHT-6001 for use on polished surfaces below 125uin

PHT-6002 for use on polished surfaces below 200uin

PHT-6005 for use on polished surfaces below 400 uin

PHT-6010 for use on polished surfaces below 600uin

- Non-Destructive hand held portable hardness tester

- Combines UCI and Leeb portable hardness testing in one state of the art device

- Test steel with min thickness of .08 and unlimited max thickness (Other materials may have larger minimum thickness levels, depending on hardness)

- Blazing fast test results

- Rockwell, Brinell and Vickers hardness test conversions shown on display

- Large Memory w/USB Output

- Choice of manual UCI probes; 1kg, 2kg, 5kg & 10kg

- Optional Motorized Probes: .30kg, .80kg, & 1kgf

- Available Impact Devices(Leeb) D, DC, D+15, G & D

Phase II Ultrasonic portable hardness tester PHT-6000 MEASURING METHOD: UCI & Leeb Portable Hardness Testers

There are two basic methods of portable hardness testing that is accepted in the field today.

“Ultrasonic Contact Impedance is based on a 136 degree diamond at the end of a vibrating rod being depressed into the test surface at a fixed load. The difference in Ultrasonic vibration frequency is then calculated into a hardness value. The UCI portable hardness tester procedure is slower than the Dynamic Impact style, however the “UCI method of hardness testing is portable, easy and accurate. It also has its own advantages when utilized for certain testing applications. UCI portable hardness testers are not restricted to large mass items like dynamic type testers. These portable hardness testers can test metals as thin as 2mm and at a hardness value as low as 20HRC (75HB). They also excel at performing hardness tests on larger, harder metals as well. Another reason for the rise in popularity is due to the fact that the UCI method is categorized as “Non-Destructive. That translates into less scrap parts/ lower mfg costs due to necessary inspections.

“Dynamic Impact is based on the Leeb principle of portable hardness,developed by Dietmar Leeb in the 1970’s. A spring loaded impact body is thrust to the test surface, effecting rebound. The speed of both the initial thrust and the rebound is measured in a non-contact mode. This is calculated as a Leeb hardness value and then automatically converted to Rockwell C, B, Brinell, Vickers and Shore Values. It has effectually brought easy, fast and accurate results to portable hardness testing

Click below to download: