Recess Inspection Penetration Gages

RECESS INSPECTION GAGES – Fastener recesses should be inspected to assure the user that the fasteners can be driven properly and effectively during assembly.

Recess Penetration Depth – this is the distance a precisely made gaging element enters a fastener’s recess. This is usually less than the “recess depth”. This measurement is an indication of how deeply a driving bit will engage in the recess.

Recess Depth – the deepest point in a fastener’s recess. This is usually a sharp point in the center of the recess.

Recess Torsional Strength – this is the ability of a recess to resist damage from driver bit camout or reaming when a rotational force (torque) is applied to the bit engaged in the recess with a specific amount of end load pressure applied to keep the driver engaged in the recess. This requirement is defined in MIL-S-87114A.

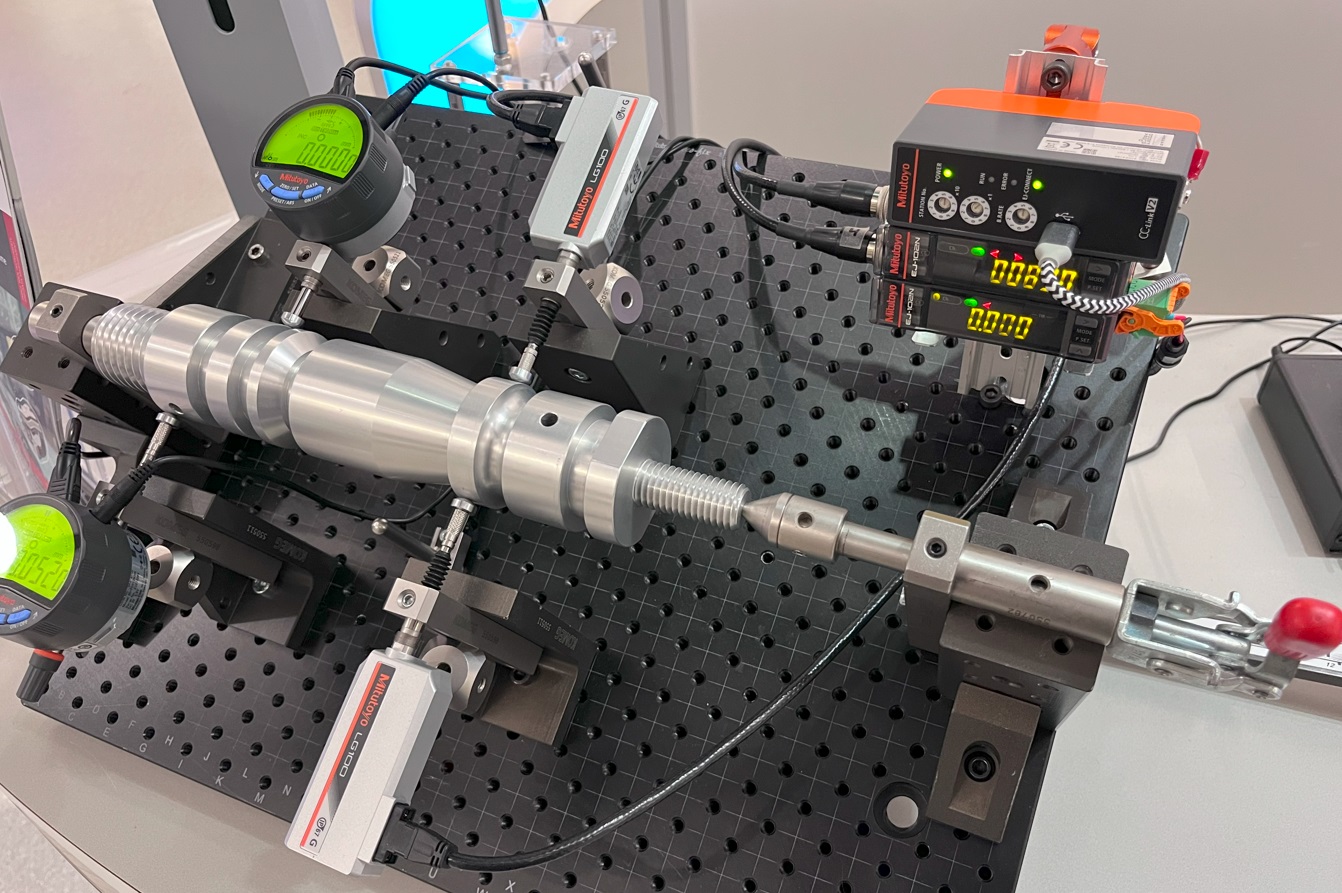

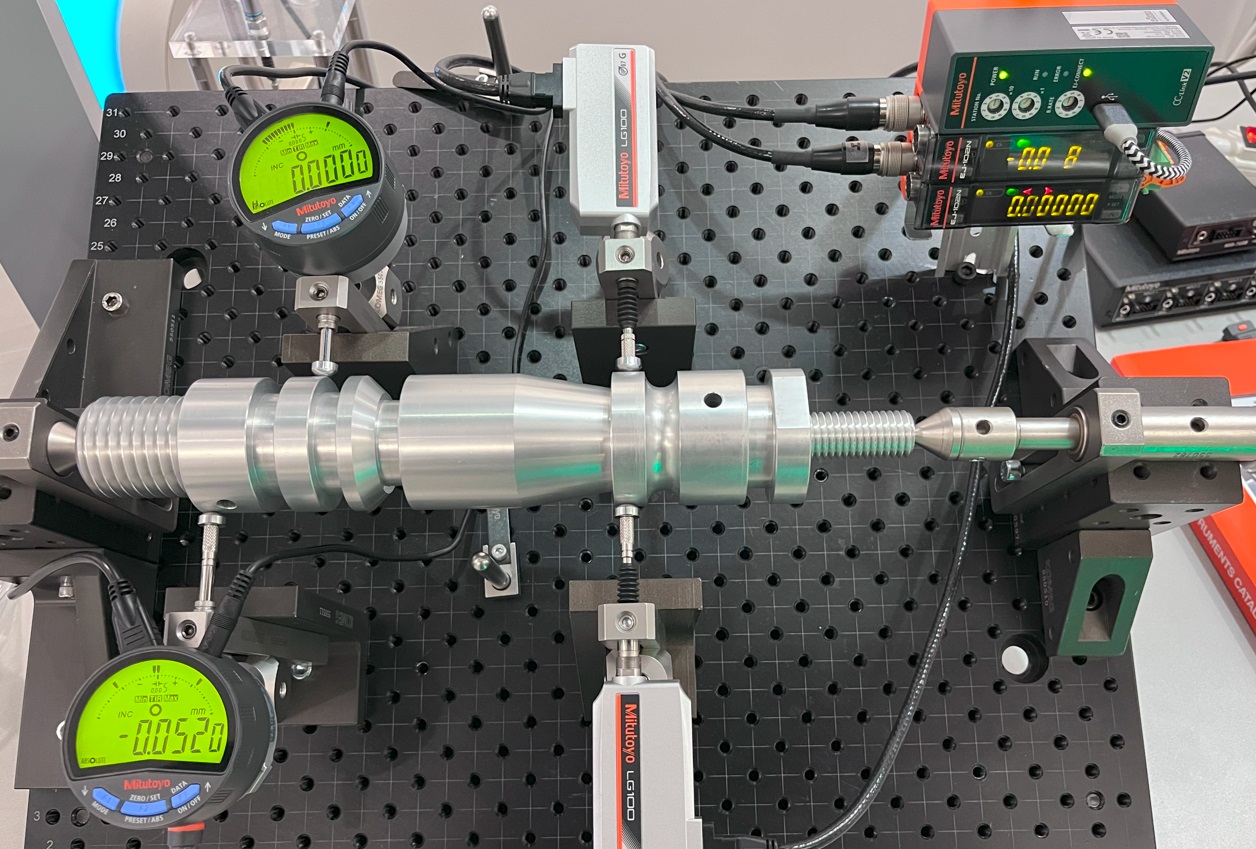

Individual Recess Gages:

These are gages designed to measure only one type and size of recess, rivet hole or slot. The standard gages are equipped with electronic, digital indicators that will read out in either inches or millimeters. Gages are available with dial indicators upon special request.

Call 866-9945-5742 or email: [email protected] for more information & to order. -OR- Fill out below quick quote form

Read More

Recess Inspection Gages:

- ANSI/ASME Type 1: Phillips #0, #1, #2, #3, #4

- ANSI/ASME Type IA: POZI-DRIVE #0, #1, #2, #3, #4

- (registered trademark of the Phillips Screw Co.)

- ANSI/ASME Type III: Square socket #1, #2, #3, #4

- Hex Socket (GO element) .050" through 9/16"; 1.5mm

- through 14mm

- 6-Lobe Recess (GO element) T-6 through T-55

Definitions:

Recess Penetration Depth - this is the distance a precisely made gaging element enters a fastener's recess. This is usually less than the "recess depth". This measurement is an indication of how deeply a driving bit will engage in the recess.

Recess Depth - the deepest point in a fastener's recess. This is usually a sharp point in the center of the recess.

Recess Torsional Strength - this is the ability of a recess to resist damage from driver bit camout or reaming when a rotational force (torque) is applied to the bit engaged in the recess with a specific amount of end load pressure applied to keep the driver engaged in the recess. This requirement is defined in MIL-S-87114A.