Download the Renishaw Additive Manufacturing product information using the link below:

Renishaw 3D Printing – Additive Manufacturing

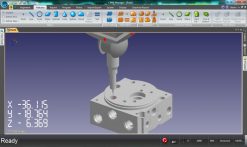

Renishaw Additive manufacturing technologies encompass laser melting, vacuum casting and injection moulding technologies. Renishaw’s laser melting process is an emerging manufacturing technology with a presence in the medical (orthopaedics) industry as well as the aerospace and high technology engineering and electronics sectors. Laser melting is a digitally driven additive manufacturing process that uses focused laser energy to fuse metallic powders in to 3D objects.

Vacuum casting is primarily used to produce high quality prototypes in a range of polyurethane (PU) resins that mimic the performance of engineering polymers. It is also possible to cast nylon and create wax masters for the lost wax investment casting process.

Injection moulding machines from Renishaw are suited to either short series production using resin tooling, or volume production of small shot components under 12 grams depending on the model chosen.

Renishaw also sells a range of materials and consumables to support our vacuum casting, laser melting and low-volume production technologies.

Call 866-9945-5742 or email: [email protected] for pricing & more information.

Read More

Renishaw 3D Printing - Additive Manufacturing:

Medical applications

Early adopters of laser melting in the medical orthopaedics sector saw benefits from the technology's ability to manufacture complex geometries and structures in high grade materials such as titanium. From patient specific hip implants to series volume production of orthopaedic implants featuring hybrid structures, laser melting has an established following in these sectors.

Industrial applications

From tooling inserts featuring conformal cooling channels through to lightweight structures for aerospace and high technology applications, laser melting significantly reduces the constraints on designers. This design freedom results in optimised structures and shapes that would otherwise be constrained by conventional processes or the tooling requirements of large volume production. Laser melting helps to reduce lead times, reduce tooling costs and permits the creation of designs not previously possible.

See Resources for full product information.