Starrett Hot Steel Gages

Starrett hot steel gage for measuring the diameter of hot steel flat stock while in the heat treatment process. The existing measuring devise utilized a gage with a crude fractional dial (right) that did not provide accurate or repeatable results. In addition, it often stuck to the hot steel and ruined the piece being measured. Even worse, on several occasions the old process caused burn injuries to the operator.

The customer needed a new solution that provided precise and reliable results, a much lower scrap rate, and ensured operator safety. The application presented some difficult challenges. Any operation that requires contact with hot steel is dangerous and must be of very brief duration.

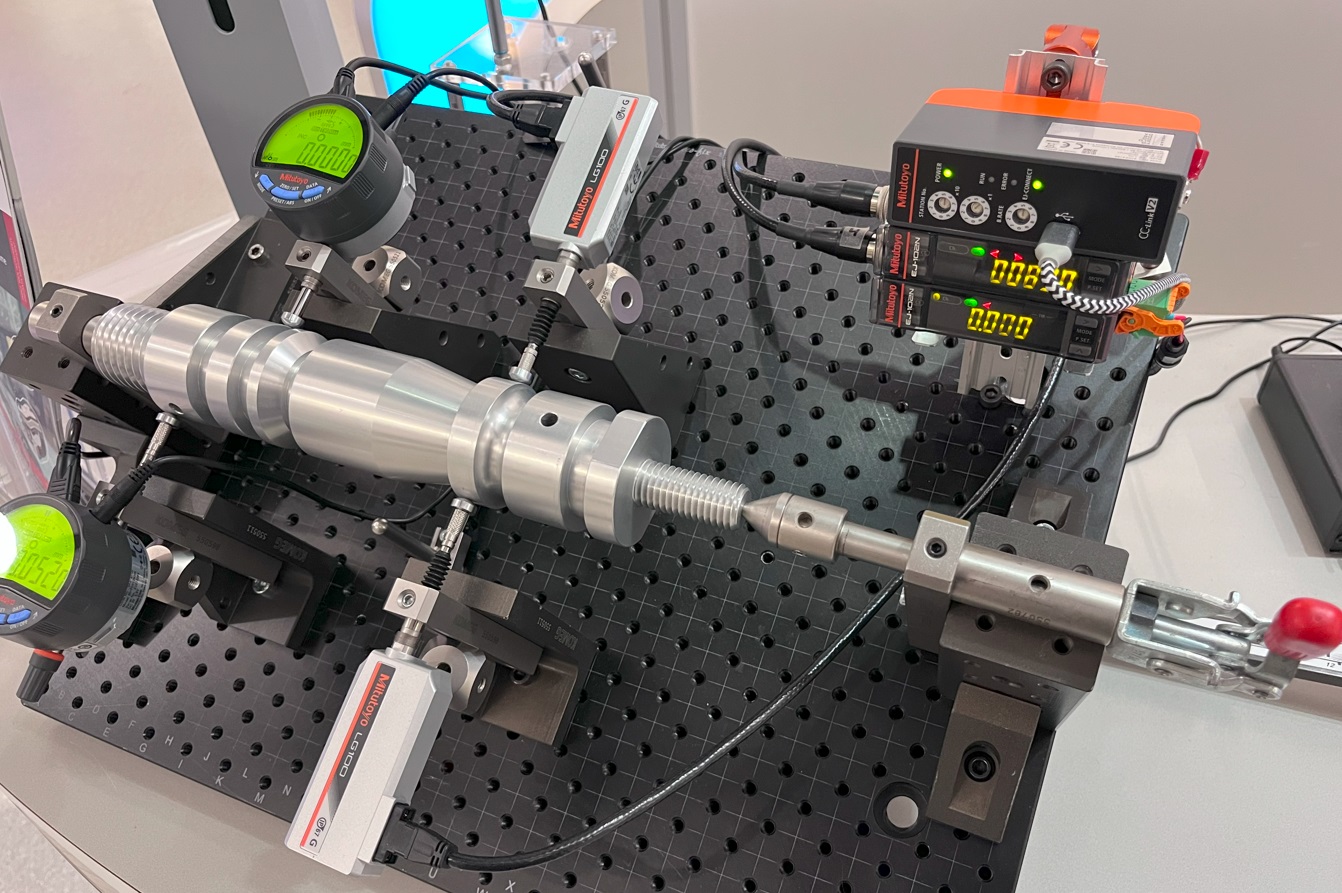

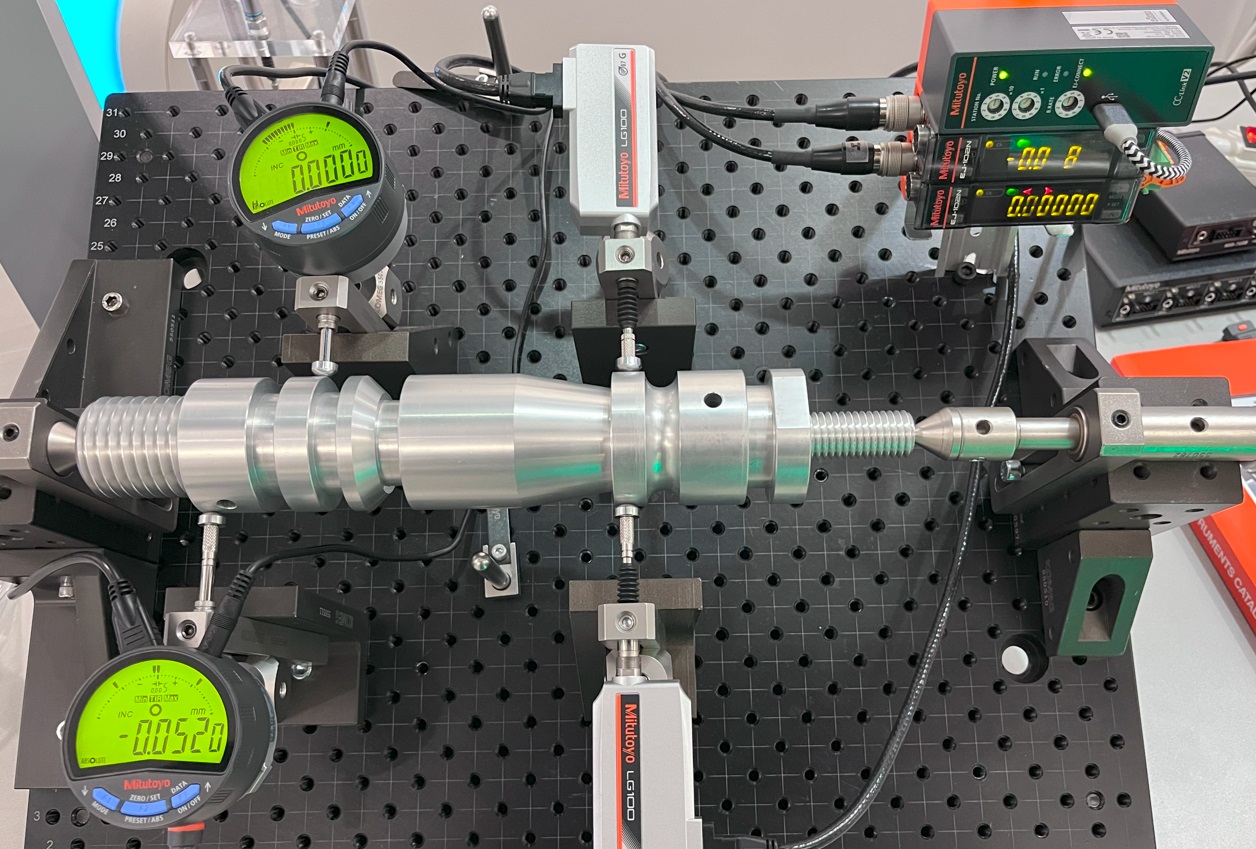

The Starrett Hot Steel Gage:

- Takes measurements quickly, contacting the hot steel for only two seconds.

- Is nickel plated to minimize heat transfer form radiant heat.

- The operators hand stays 12 away from the hot steel.

- The electronic indicator’s Hold feature locks the reading in the display so it can be safely read away from the dangerous area, and in better light conditions.

- Is very accurate, measuring to within +/- .003″.

See below for specifications.

Call 866-9945-5742 or email: [email protected] to order & for more information.

Read More

Starrett Hot Steel Gages Features:

Measuring Process with the Starrett Hot Steel Gage

- First, turn on indicator and check the accuracy for the size being measured with the gage master.

- Then, with the jaws open, press “HOLD to display MIN on display.

- Next, place gage over part to be measured with handle parallel to work surface and pull trigger to close jaws.

- Move the handle slightly above horizontal to slightly below while maintaining trigger pressure.

- Then, release the trigger and remove gage. The measurement is displayed on indicator.

Capacities of up to 8" (in 1" increments) and a choice of 2" or 3" in-reach capacity. Special models with modified jaws are available for measuring round stock.

An Ideal Application for DataSure Wireless Data Collection. An important part of the process is to use the Hold function of the indicator, so the measurement will be recorded before the jaws leave the part. In addition, many manufacturers require measurement data to be recorded. The electronic indicators that do the actual measuring are available with output ports.

- Takes measurements quickly, contacting the hot steel for only two seconds.

- Is nickel plated to minimize heat transfer form radiant heat.

- The operators hand stays 12 away from the hot steel.

- The electronic indicator’s Hold feature locks the reading in the display so it can be safely read away from the dangerous area, and in better light conditions.

- Is very accurate, measuring to within +/- .003".