Valve Seat Measurement Gage

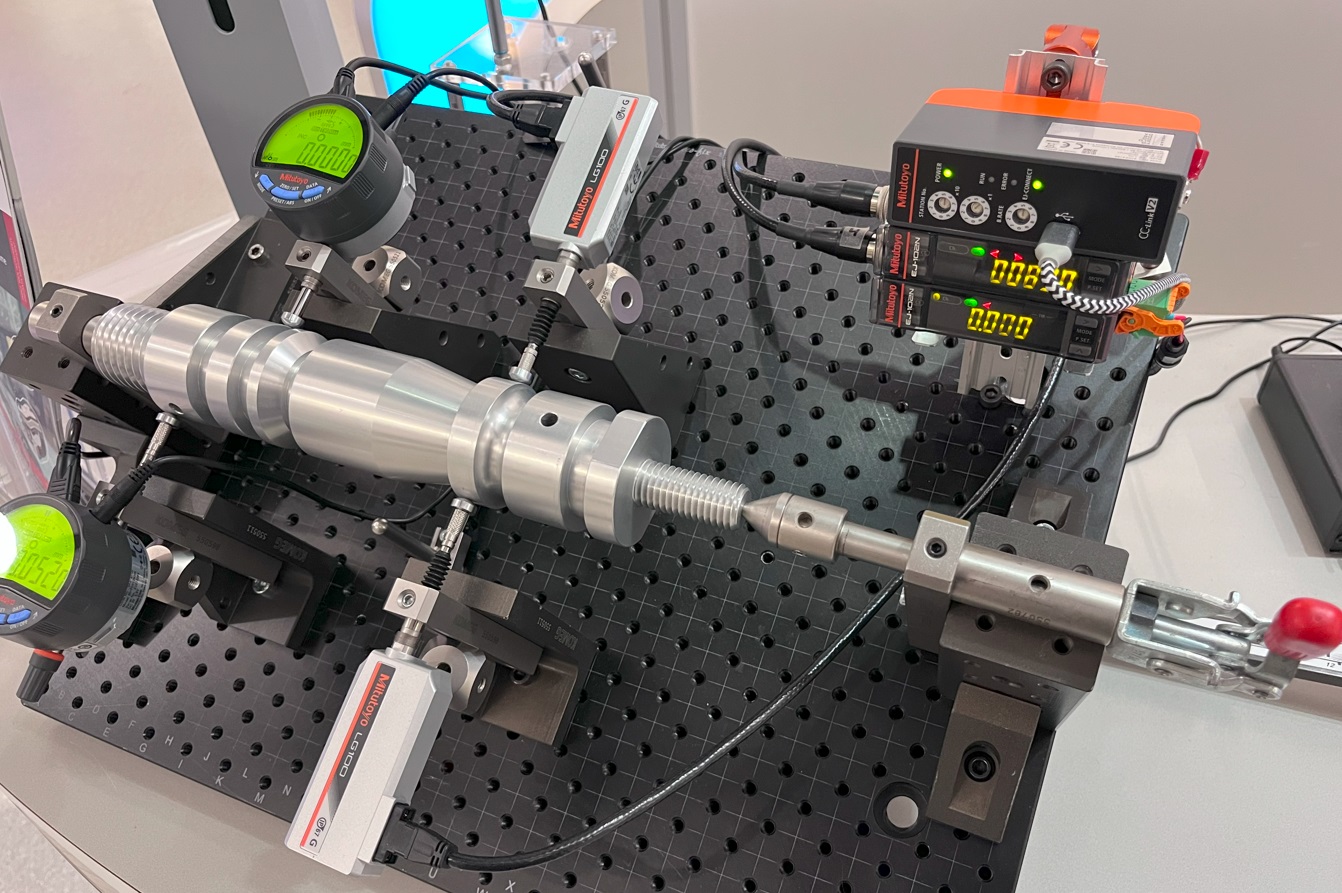

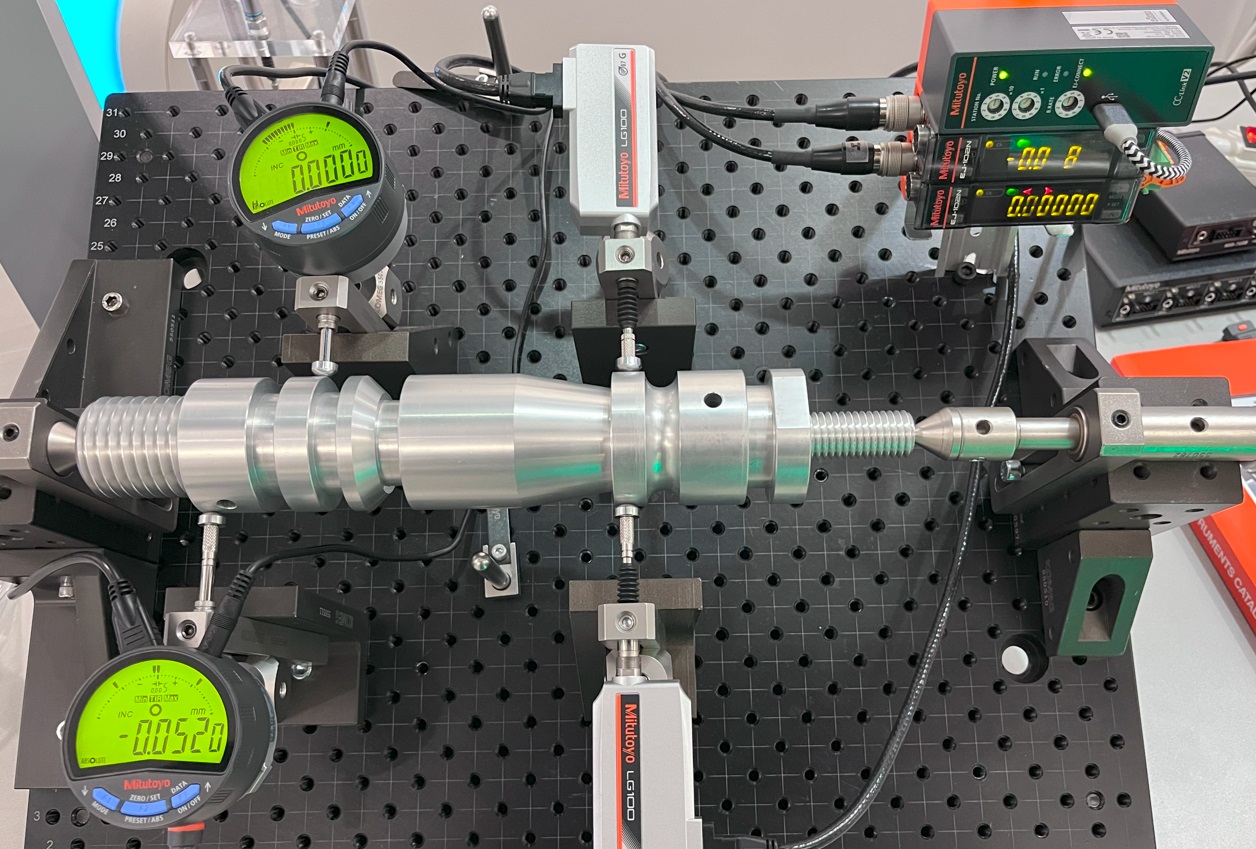

These measurement gages are suitable for the quality control of the cylinder head across many market sectors, including gas and diesel engines for two wheelers, light and heavy weight vehicles and others. These gages are a cost-effective solution for runout and roundness inspection of valve seats: rapidity and ease of use make this gage the perfect tool for any manufacturing dimension.

The operator introduces the gage into the valve guide and starts the measuring cycle by pressing the button on the plug handle or on external push-button. The automatic rotation allows to quickly perform the measures of runout (between valve seat and guide) and roundness (of the seat), processing the signals from two different probes located in the plug nosepiece, in combination with the mechanical reference of the gauge.

It performs two dynamic inspections, by rotating and scanning the entire valve seat in the same cycle, providing the runout, roundness and the measures of angles, seat straightness and seat length. Upon request, it can also run a custom inspection cycle to expand the number of features to be controlled in the valve seat.

The special transmission joint and the pre-centering guide protect the measurement cycle against operator movements, minimizing their effects. Several modes to use the gages: free hand use, free-standing system with pre-centering guide, moved with a mechanical fixture or, in some specific cases, also on automatic system.

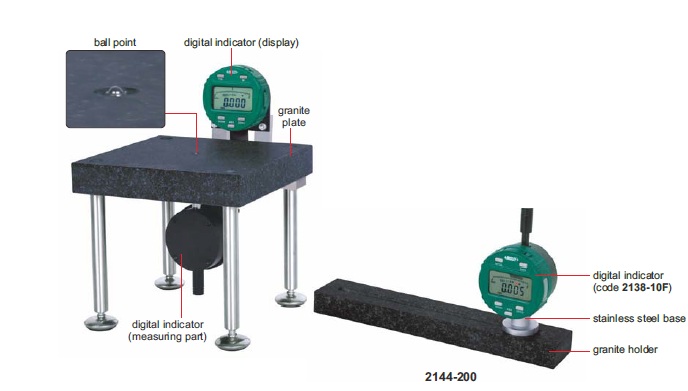

the software platform designed to drive the user all along the inspection plan of the cylinder head and during zeroing operations.

The standard scope of supply is composed by two plugs for intake and exhaust seats, the relevant masters, GAGEPOD™ MC8 driver units, supports and software. An industrial or commercial PC with Quick SPC installed is required to run and manage the application program.