| Model: | RTX-0605-A |

|---|---|

| Technology: | Automated |

| Units: | Inch, Metric |

| Table Adjustment Method: | Automatic |

| Table positioning drive speed in CNC mode: | 30 (Max rpm) |

| Table Diameter: | 11.8″ / 300mm |

| Table Centering Range (With DAT function): | ± .2″ / ± 5mm |

| Table Leveling Range: | ±1° |

| Max Table Loading: | 132lbs / 60kg |

| Table Max Probing Diameter: | 14.1″ / 358mm |

| Table Max Loading Diameter: | 26.8″ / 680mm |

| Column Traverse Method: | Motorized |

| Column Drive Speed (Max): | 100mm/s |

| Column Drive Speed using remote box mode (Max): | 40mm/s |

| Column Measuring Speed: | 0.1, 0.2, 0.5, 1, 2, 5mm/s |

| Narrow Column Straightness (λc2.5): | (λc2.5) 0.10 / 100μm/mm |

| Wide Column Straightness (λc2.5): | (λc2.5) 0.25 / 550μm/mm |

| Column parallelism: | 1.2 / 550μm/mm |

| Column Max Probing Height: | 21.6″ / 550mm |

| Radial Traverse Method: | Motorized |

| Radial Drive Speed (Max): | 100mm/s |

| Radial Drive Speed using Remote Box mode (Max): | 40mm/s |

| Radial measuring speed: | 0.1, 0.2, 0.5, 1, 2, 5mm/s |

| Radial Straightness (λc2.5): | (λc2.5)0.7 / 150μm/mm |

| Radial Squareness: | 2.0 / 150μm/mm |

| Detector Measuring Direction: | One-direction |

| Data Sampling Points: | 14,400/rev |

| Air pressure: | 0.39 Mpa |

| Main Unit Dimensions: | 50.5 x 26 x 64.2″ / 1282 x 660 x1630mm |

| Main Unit Mass: | 2183lbs / 990kg |

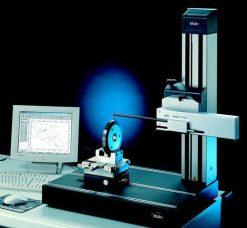

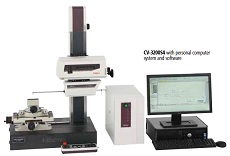

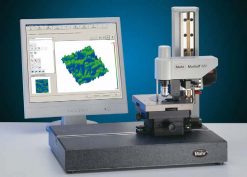

Mitutoyo RTX Roundtracer Extreme CNC Roundness & Cylindricity Measurement

Mitutoyo RTX Roundtracer Extreme RTX-0605-A all-in-one measuring system that integrates roundness, contour and surface roughness measurement functions in a single device to save time and improve productivity. This advanced CNC machine utilizes speed, accuracy and operability at the highest level to measure a wide variety of workpieces with various geometries, such as camshafts and bearings.

Key features and capabilities with the Roundtracer Extreme measuring system include:

The new motorized sliding axis, detector and detector holder gives it the ability to change the stylus angle, making it easier to perform inside diameter measurements of thick workpieces while avoiding interference.

Higher reproducibility and best-in-class theta-axis drive speed is achieved through increased turntable rigidity.

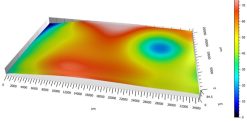

Increased maximum measuring diameter, support for 3D surface texture measurement and lead (twist) analysis

Roundtracer Extreme features best-in-class speeds with a maximum of 100mm/sec with improved positioning accuracy and greatly reduced positioning times compared with conventional models.

The ergonomic remote box enhances the user’s experience with clearly laid out buttons and controls

Roundpak V8.1 include:

• NEW Status Monitor support.

o This is a tool utilization application to allow user to monitor usage.

• NEW Mitutoyo Launcher support.

• NEW tolerance check and velocity analysis for harmonic analysis results.

• NEW “Profile Any Line” can be calculated based on rotational and linear measurement data.

• Workpiece Centering/Leveling by partial circle measurement elements is added.

• Part program files can be saved in an older format so that they can be opened in the previous versions of Roundpak V8.0, V7.4 or V7.0-V7.3.

• The current theta-axis counter value can be reflected as the measurement angle position of the linear measurement.

• Supports the 64-bit Security Manager same as its 32-bit version.

Other new functions and features include:

Gaussian Regression Filter

• Supports Robust Gaussian Regression filter according to ISO 16610-31:2016.

Better Efficiency

• Multiple linear elements can be joined and analyzed as one element.

Cylindricity Analysis

• Supports cylindricity analysis that uses rotational and linear measurement data known as “B Cylindricity” specified by ISO12180-2:2011.

Workpiece Leveling

• Workpiece leveling using one linear element is added.