Mitutoyo Shaft Measuring Unit- Diameter, TIR, Length, Straightness

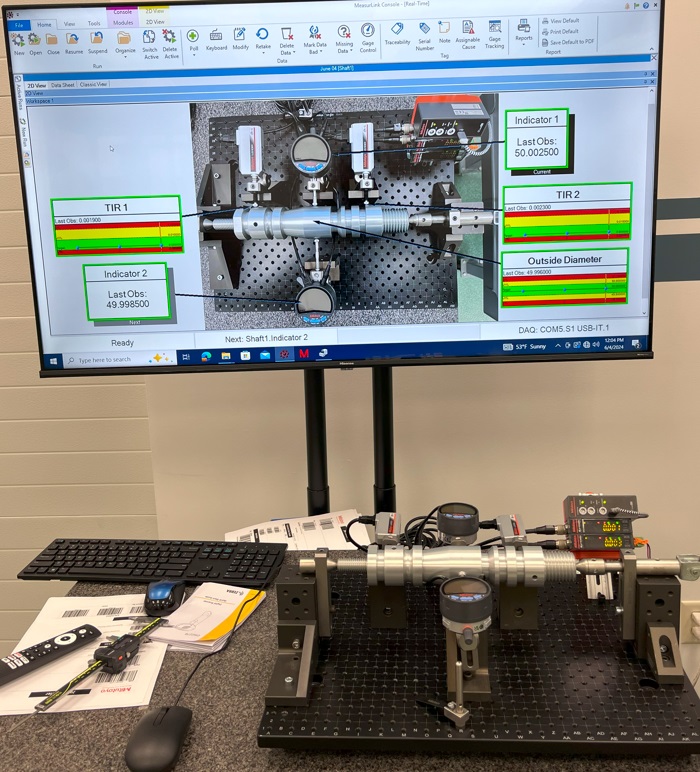

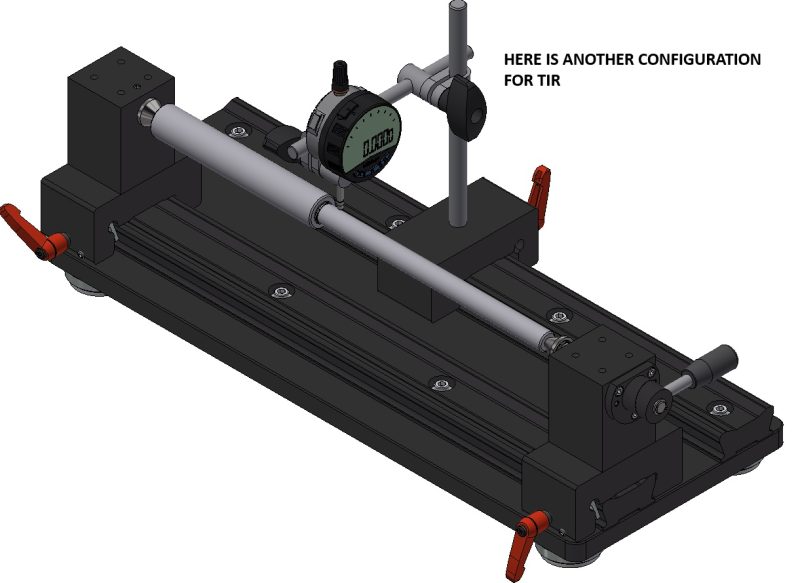

Measure component characteristics TIR, length, diameter and straigthness can be measured using an individual combination of indicator, probe and Laser Scan Micrometer (LSM) and evaluated with Measurelink. MeasurLink, allows setting indicator presets and zero multiple gages with a single button press.

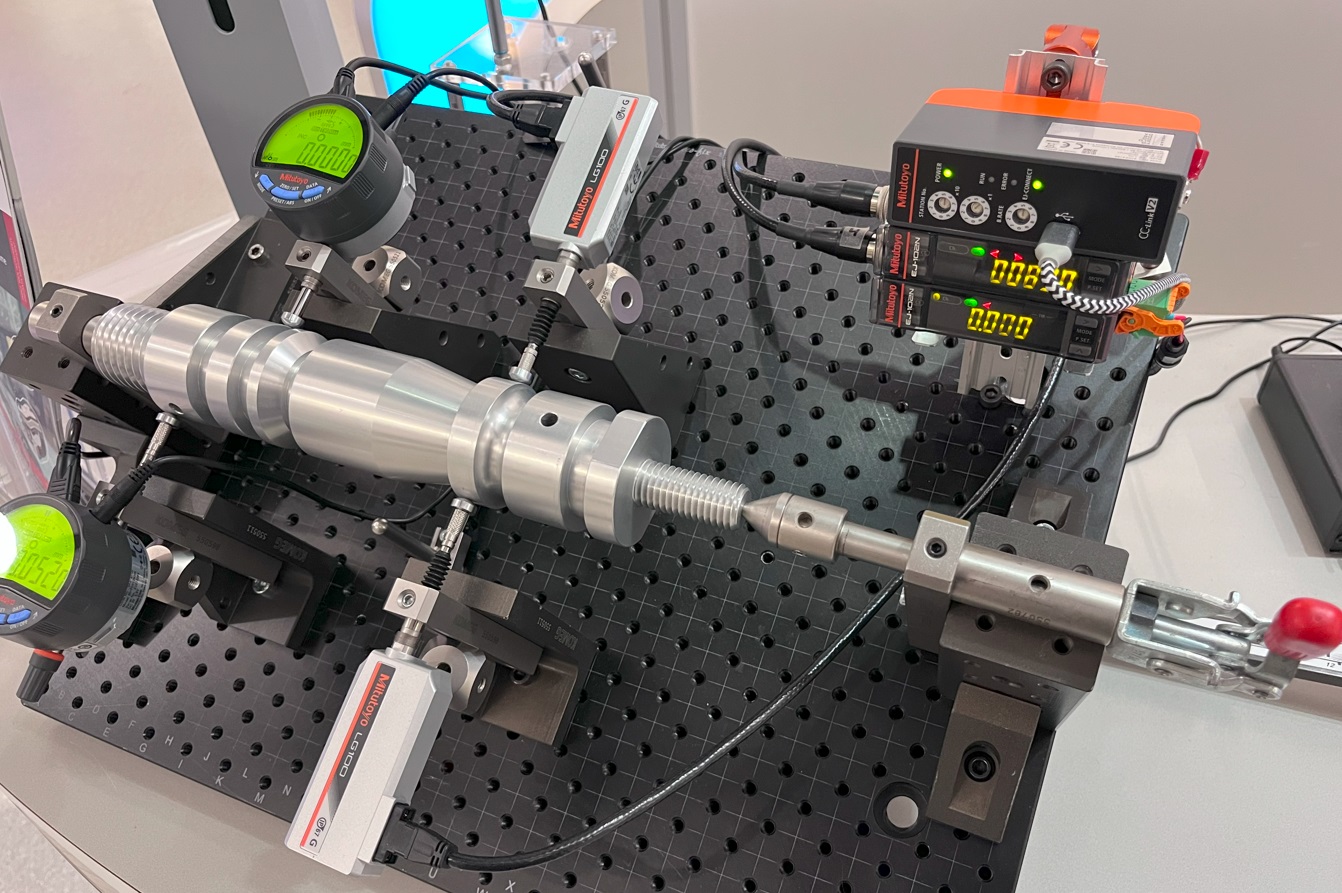

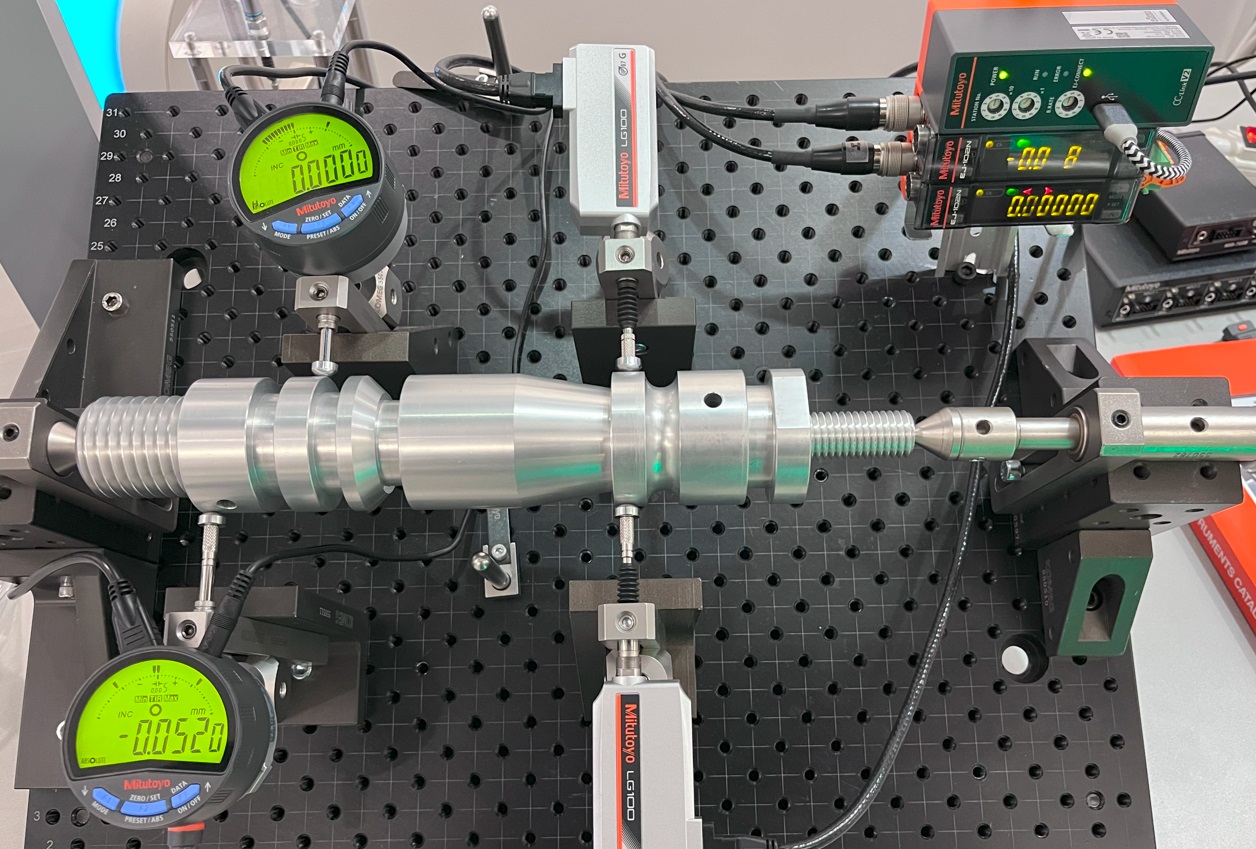

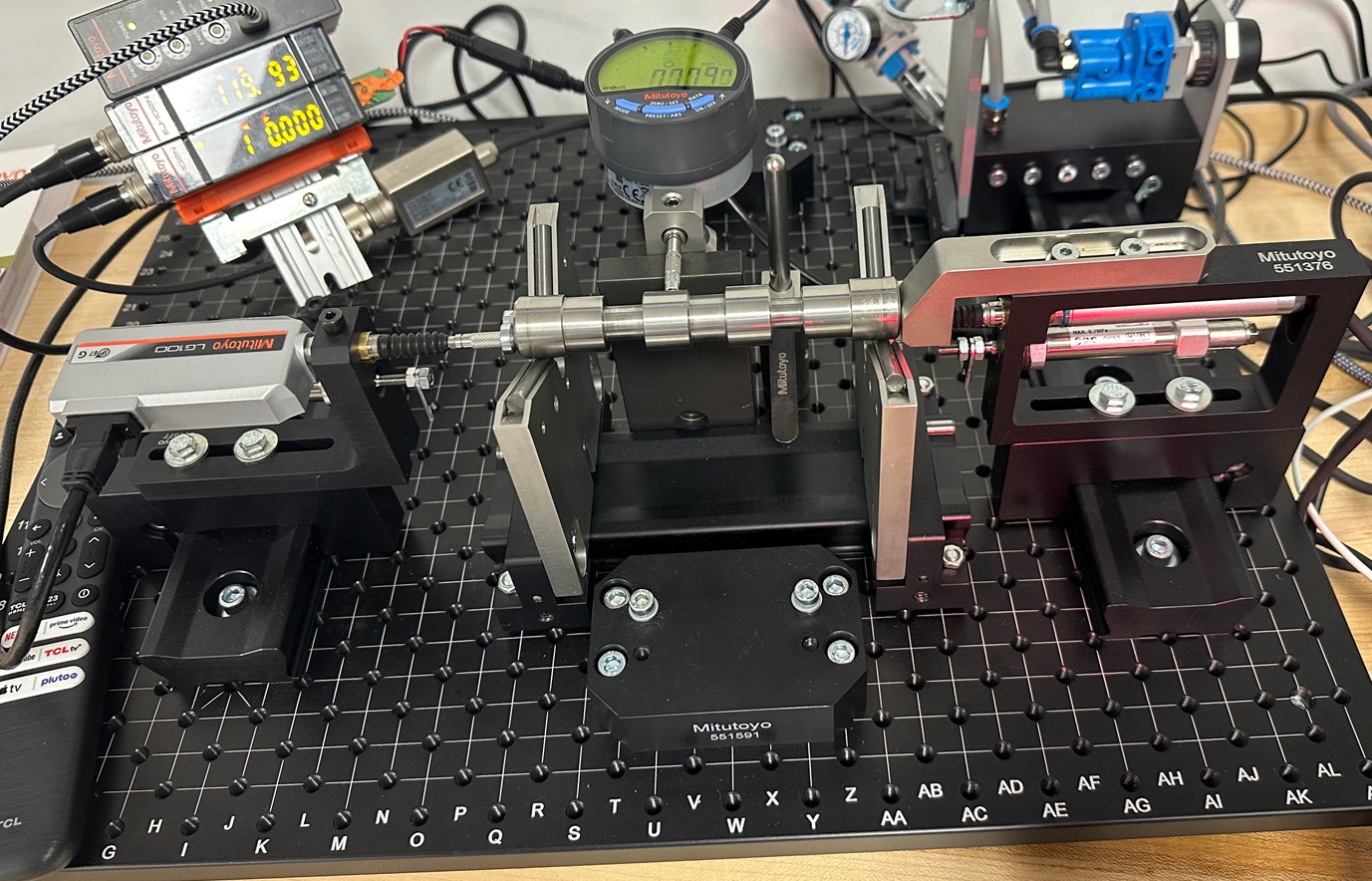

The components that I’m using are a combination of:

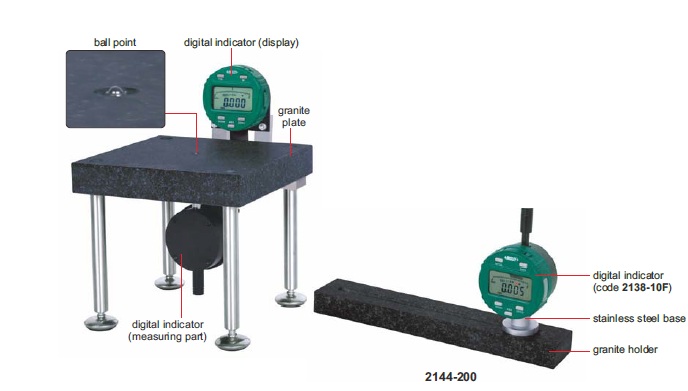

- Komeg Shaft Measuring Kit

- Indicators and associated cables

- MeasurLink Real-Time Standard

- (optional) Linear Gages with EJ Counter and USB module

- optional laser micromter

add an indicator at the end of the part to measure length.

Straightness could be measured as well if the part or gage were to slide.

With a high accuracy indicator, you can get 0.0001”. Replacing indicators with linear gages and laser micrometer can improve the accuracy quite a bit.

Option

Bi-Directional Communication with MeasurLink Support for S1 Digital Tools

Experience seamless control and communication with S1-enabled gages—right from MeasurLink Real-Time.

With version 10.4, users can power on gages, perform zero, preset values operations, and access critical stored information such as calibration dates and serial numbers—all directly through the software interface.

Enhanced Support for Mitutoyo S1 Gages in MeasurLink 10.4 MeasurLink 10.4 now includes foundational support for several key functions of Mitutoyo’s latest S1 gages, streamlining both data collection and gage management workflows:

•Power on multiple gages

•Perform zeroing and preset value operations

•Reset peak values

•Change gage modes

•Retrieve calibration date and serial number

•Identify measurement units and gage resolution

•See a real time graph and value of the gage reading without taking data

•Continuous poll data at a specific time frame

This integration marks a significant step forward in improving efficiency and usability for users of Mitutoyo’s advanced S1 gage technology.

Benefits

In addition to the other benefits of using MeasurLink (i.e.: SPC process improvement, reporting, work instructions, etc.), users can expect:

•Increased efficiency with single button operation

•Improved ease-of-use with single button operation

•Risk mitigation and improved auditing with automatic traceability to the gage

•Eliminate human error when creating new gages in Gage Management