Modular Gaging and Fixture Concept

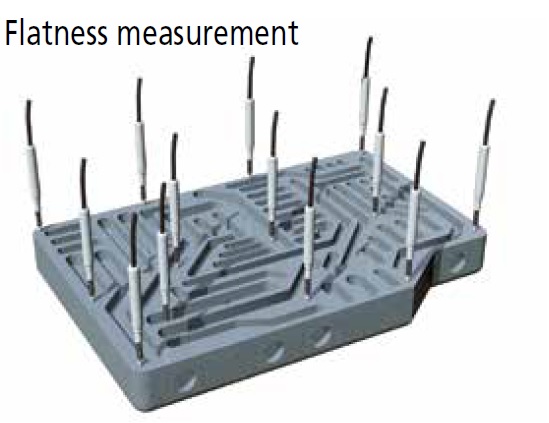

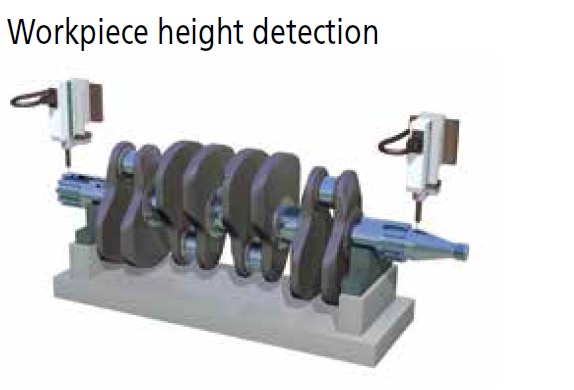

The idea behind modular gaging fixtures is to take all the elements found in high-precision, comparative gaging and turn them into reconfigurable, modular components.

Comparative gages consist of basic, common components. For example,comparative gages have solid reference anvils, a sensitive contact, part refer ences (backstops) and a readout,all mounted on a stable frame. The use of standard components enables flexible measuring devices to be designed and assembled for a wide range of workpieces. Common elements enable them to be reconfigured for similar or different applications. Whereas a traditional comparative gage might be built for one size shaft with five diameters, a modular gage can be adjusted with relative ease for five diameters of different sizes and at different locations.

Modular gaging elements can be configured for simple or complex workpiece geometries. Keeping the design of the modular components.

Call 866-9945-5742 or email: [email protected] for more information.

Read More

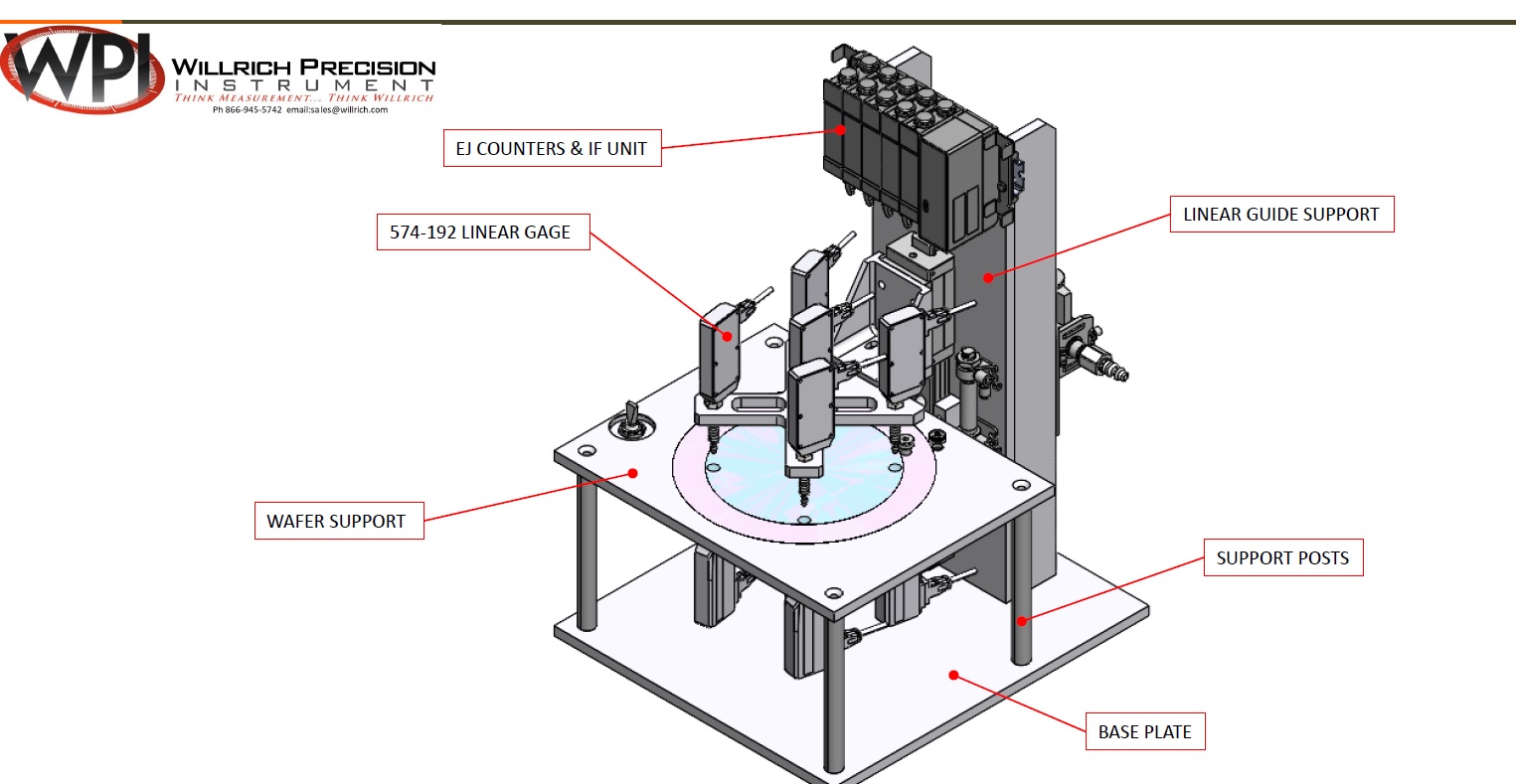

Modular Gaging and Fixture Concept - Millimar Standard Elements:

Benefits of a flexible, modular system include:

- Reusability of standard elements. Once production of a particular workpiece has ceased,

- standard elements can be reused for another workpiece.

- A choice of different mechanisms for guiding the moving part of the stylus, selectable for the accuracy requirements of the measuring task.

- Reduced development and implementation time.

- Availability of the equipment: standard elements can be stocked by the supplier for immediate delivery when new gaging require ments emerge.

An initial gaging system can be constructed by the customer using standard elements obtained from a catalog. Alternatively, these elements can be ordered as a complete solution for the first setup, and then changed later as needed.

Modular, flexible gaging systems are still under active development. As noted above,these systems are not intended to replace either lower precision handheld gages such as calipers and micrometers, or higher-precision tools such as snap gages, bench stands or more traditional 10/00 gages. Rather,these systems are intended to complement existing gages to help adapt inspection

methodologies to an evolving manuÂfacturing environment.