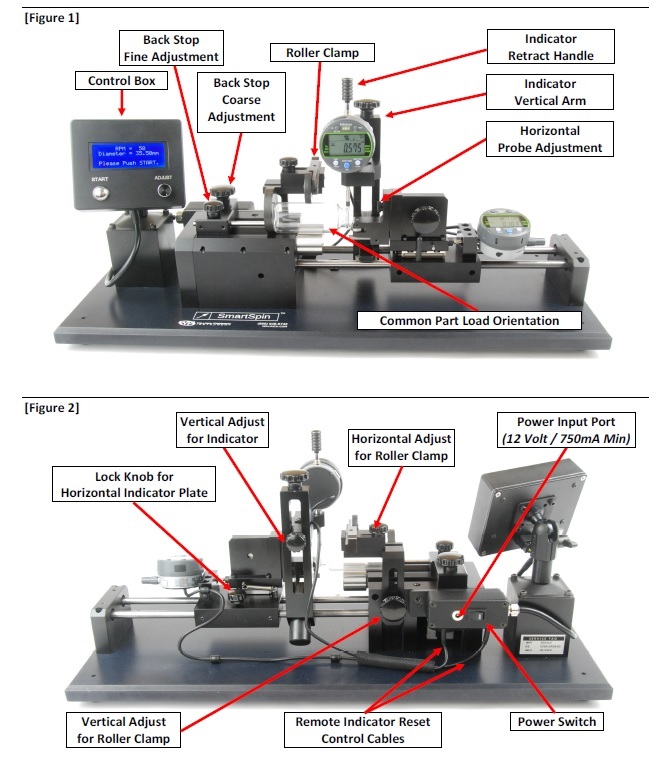

Smart Spin Gage for Concentricity, Run Out and Perpindicularity

The NEW SMART SPIN Gage is designed to quickly measure cylindrical parts for outer diameter run-out, and part edge run-out (perpendicular to body diameter). To accommodate various size and style of parts, the device includes an adjustable backstop, overhead roll clamping, vertical and horizontal probe positioning. An integrated a STEPPER motor with specialized drive control hardware and software allows for precision

rotation and remote indicator RESET. These features allow for reliable results with proper setup for countless part shapes and sizes within a certain part size range. Two speeds are available for part testing: 10 and 20

RPM. we are able to offer an upgrade allowing for variable selection of the motor speed up to 40 rpm’s

Read More

Operation:

CONTROLLER BOX

Drive Speed: Press ADJUST knob to toggle drive speed. (50 / 100 RPM)

Part Diameter: Rotate ADJUST knob to select part diameter. (6.25mm to 51.00mm)

Run Test Cycle: Press START to begin test cycle.

Indicator Zero Mode: Press & hold ADJUST knob for about 8 sec to toggle modes. (Auto/Man)

Jogging (Continuous wheel spin) Press & hold START button for about 3 seconds. Press START again to stop.

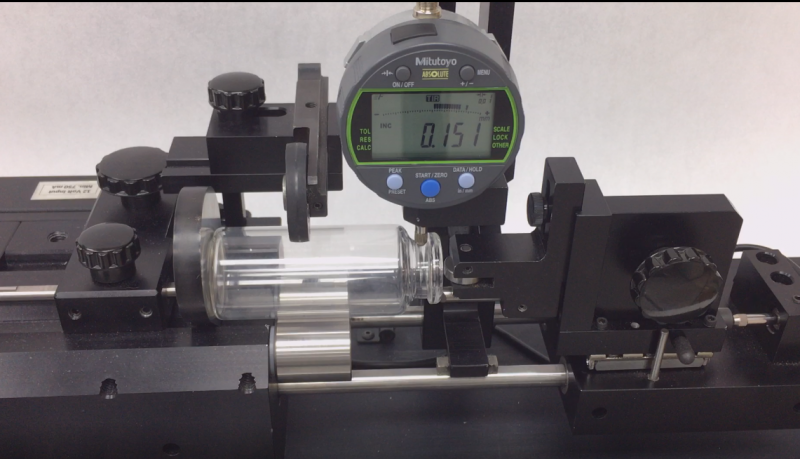

DIGITAL INDICATORS (Mitutoyo 543”302B)

Both indicators must be set in TIR mode. Press “PEAK button on face of indicator several times until TIR appears on indicator display and then press the blue “START button on the indicator face to begin TIR mode.

MEASUREMENT RANGE

Device is designed to hold cylindrical parts and dimensionally measure run”out on outer diameter and edge run”out. (Perpendicular to OD) Capacity: 6.25mm to 51.00mm diameter, 25mm to 150mm long

Click below to download the PDF

SmartSpin Operator Manual rev 10-12-2018

SMARTSPIN quickstart hand held

Click below to play video on the Smart Spin

Total Indicator Reading (TIR) and total runout are both measurements used to assess the accuracy of a round object, but they have distinct differences:

- **Total Indicator Reading (TIR):** This is a measure of the variation in a surface as it rotates around a datum axis. TIR is the difference between the highest and lowest points recorded by a dial indicator as the object is rotated. It represents the maximum deviation of the surface from a perfect circle. TIR is often used to check the concentricity and roundness of cylindrical parts.

- **Total Runout:** This is a more comprehensive measurement that includes both the roundness and the axial alignment of a surface. Total runout measures the combined effect of variations in the surface profile and any axial displacement or tilt as the part rotates. It is assessed along the entire length of the surface, providing a single value that reflects all geometric deviations, including circularity, straightness, and coaxiality errors.

In summary, TIR focuses solely on the roundness in a single plane, while total runout encompasses roundness along the entire length of the surface, including any axial misalignment