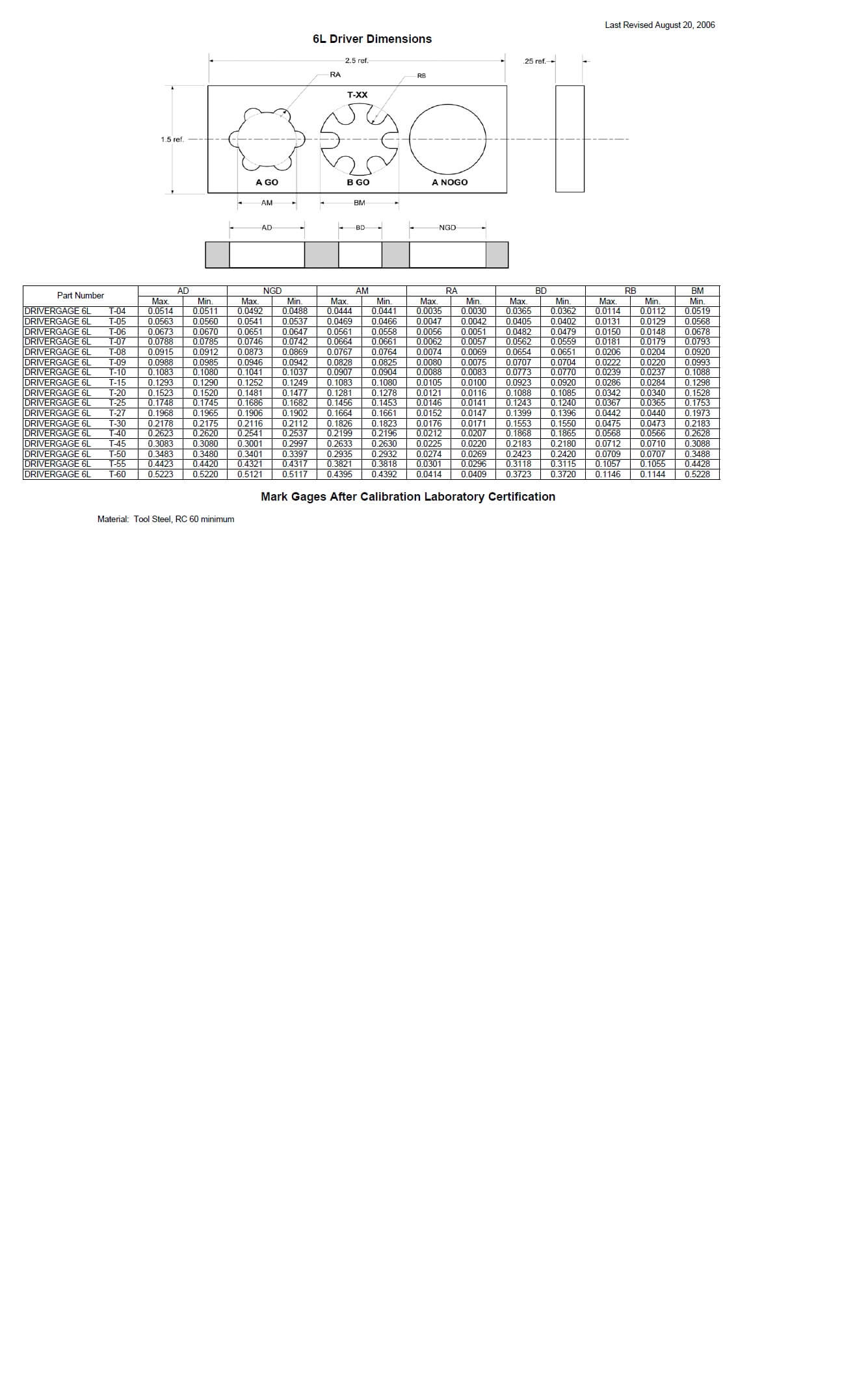

Hexalobe Gage

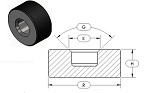

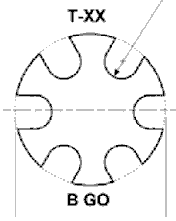

Hexalobe gages are made as GO and NOGO pairs. Each gauge is designed to be held by hand and inserted into the torx hole. If the NOGO gage fits, then the hole is too large and the part fails inspection. If the GO gage fits, then the hole is the right size and the part will pass inspection. If the hole was too small the GO gage would not have fit inside.

Torx Gages can also help to determine if there is too much twist in the form, a common troubleshooting feature of holes manufactured using the rotary broaching process. Our Torx Broach gages are made of durable hardened M-2 tool steel. All gages come with handles featuring green caps on the GO gage side and red caps on the NOGO side. NAS1800

Read More

6-lobe hexalobular made as GO and NOGO pairs. Each gauge is designed to be held by hand and inserted into the torx hole. If the NOGO gage fits, then the hole is too large and the part fails inspection. If the GO gage fits, then the hole is the right size and the part will pass inspection. If the hole was too small the GO gage would not have fit inside.

All gages come with handles featuring green caps on the GO gage side and red caps on the NOGO side. NAS1800 (ISO 10664)

T-06

T-08

T-10

T-15

T-20

T-25

T-27

T-30

T-40

T-45

T-50

T-80

What is the difference on hexalobe gage standards NAS-1800 VS ISO 10664

Answer: The go member is the same between the two standards. The nogo member is different, the nogo checks the inside lobes unlike the ISO 10664. There also a different tolerance on the lobe radius and over lobes measurements.