Whether you find yourself in the lab, on the shop floor, or out in the field, the key to success is having reliable, portable, metrology-grade 3D scanners at your disposal.

- Creaform HandySCAN 3D | Black Series – Blue: This is a high-accuracy portable 3D scanner designed for precision measurement applications.

- Creaform Go!SCAN 3D White Light Technology: Go!SCAN 3D is known for its innovative white light technology, which is ideal for capturing detailed 3D scans.

- Creaform HandySCAN 700™ | Elite Blue Laser: The HandySCAN 700™ is a top-tier blue laser 3D scanner known for its precision and accuracy.

- Creaform HandySCAN 3D Portable Metrology-Grade 3D Scanners: This series represents a line of metrology-grade 3D scanners optimized for various applications.

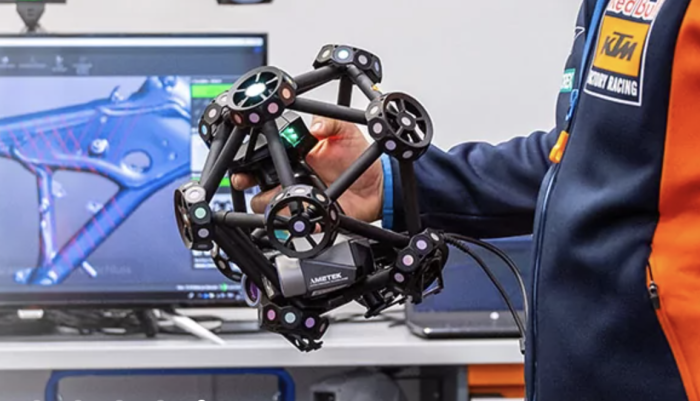

- Creaform MetraSCAN 3D 3D Scanner and Portable CMM for the Shop Floor: MetraSCAN 3D is a versatile 3D scanner and portable CMM system tailored for shop floor needs.

- Creaform HandySCAN 3D | Max Series: The Max Series is a powerful addition to the HandySCAN 3D lineup, offering advanced features and capabilities.

These tools are designed to excel in terms of ease of use, accuracy, resolution, reliability, and lightning-fast data acquisition, ensuring you get the job done right, every time. Don’t miss the opportunity to enhance your precision measurement capabilities. Contact us at 1-866-945-5742 or email us at [email protected] for pricing and to schedule your demo.

View the entire line up on our website. https://willrich.com/?s=CREAFORM&post_type=product