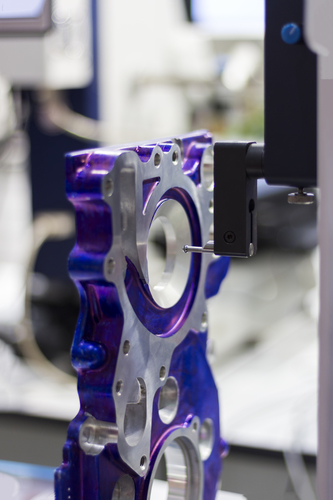

A height gage is a measuring instrument designed to measure the height of a workpiece. It features a slider and measuring stylus. These components move relative to a measuring scale that is attached to a beam. They move along a single vertical axis, which is nominally perpendicular to a reference plane. That plane is typically fixed on the instrument base. Today, height gages are a valuable asset when it comes to quality control. If you are looking to get one, you have come to the right place. In this post, you will explore different types of height gages and learn how they work!

Option A: Electronic / Digital Height Gages

The first option that you can consider is a digital or electronic height gage. Digital versions of height gages are divided into three distinct groups:

- Group one: Height gages in this group often feature data output, floating zero, absolute zero, and metric/inch conversion.

- Group two: Height gages in this group come with all the first group’s features. The accuracy of the tool, however, is a magnitude of order better. They may also come with additional features such as probe compensation, TIR, max/min, ID/OD measurement, and tolerance setting.

- Group three: Height gages in this group have all the features that were mentioned in the second group. These gages, however, feature a higher accuracy rating. Most of them also have the ability to store and generate programs, motorized touch probes, air bearings, and computer interfaces (enabling SPC). You can use these height gages to measure a part feature in two dimensions. You just need to rotate the workpiece. Technicians can use gages from this group if they wish to reduce the demand on their CMMs and when higher accuracies are required.

Option B: Mechanical Height Gages

Depending on your company’s budget and needs, you may also consider mechanical height gages. This type of height gage has been utilized in flat plate layouts for many years. The three basic types of mechanical height gages include:

- Digital counter height gages: The readings are clearer than Vernier scales and often feature dual-digit and dial counters. These features help decrease the time needed to lay out a part. The dual-digit counters can be used as a floating zero or set at the reference datum.

- Dial height gages: These gages are compact in nature and are often available in sizes below 300 mm or 12 inches. If you are looking to get a personal height gage, this option suits you better. What’s more, it can be easily stored in a machinist’s toolbox.

- Vernier height gages: These gages can feature one or two scales on the beam (both metric and inch). Their main advantage over other height gages is their height! They are available from six inches to six feet in height.

Now that you have a better understanding of the available types of height gages and their features, it is time to get one! If you can’t decide on which height gage to get, do not hesitate to contact Willrich Precision for advice.