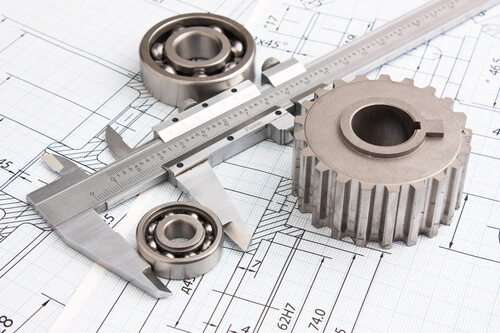

It is certainly surprising that some technicians know little about the precision measurement tools they use on a daily basis. In some cases, there may be a lack of resources to give accurate descriptions about what these tools are and what they are really designed for. This lack of knowledge may lead those technicians to buy and use the wrong tools for specific jobs.

For example, you can find a material that will describe a precision micrometer as a miniature vise and this is not correct. When you enter a typical tool shop, it is almost impossible to grasp all that is around unless you have a personal experience with these tools. We will take a look at some of the common precision measurement tools and what they are used for.

Granite Surface Plates

Granite surface plates are flat surfaces designed to hold components that are to be inspected and inspection tools. These surfaces are big, flat rocks and they have a .0001 variation in the surface flatness. A surface plate is designed to be very flat so that it can allow accurate measurements to be taken. If the measuring surfaces were irregular, that could tamper with the results and produce inaccurate readings.

Precision Micrometers

These are the most commonly used measuring tools. They were invented over two centuries ago and the amazing part is that they have not changed at all since then. These tools are used to measure components less than one-eighth of a hair.

Dial Indicators

These tools resemble a watch that has a needle sticking out on one side. The tool takes measurements when the needle attached to the hand on the dial moves when passed over a surface. These tools are used in most industrial applications and they can be found in most tool shops, manufacturing plants and inspection areas.

Optical Comparators

These tools resemble a film projector. When you place your hand in front of it you can be able to see your shadow on the wall. The only difference is that the image cast is magnified in exact amount and then cast on a screen that is calibrated. What this means is that the shadow that is casted has the same dimensions as the workpiece being inspected.

Gage Blocks

Gage blocks are small carbide or steel blocks that come in a certain size. When you look at their design, they are simply just blocks. However, these tools play a very important role in laying out the foundation for all measurement in a tool and die shop or mold making. They can be stacked as high as needed in order to compare your workpiece with. If there are differences, the stacks are adjusted until they match the workpiece.

Pin Gages

Pin gages are pretty similar to gage blocks, only that they are rounder in shape. They are mainly used to check holes for size. To determine the size of a hole, you use a pin of a known diameter and test it in the hole until you get the measurements.

Are these tools important? These tools are very important because they help manufacturers to produce components that fit very precisely in order for them to function effectively.