The 1200 series laser distance sensor delivers a complete non contact laser displacement measurement system complete in one compact package. This sensor uses laser triangulation to accurately measure distances from materials detect such as metals, rubber, plastic and wood products.

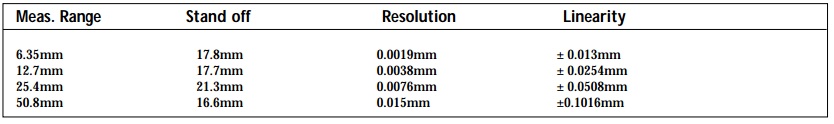

The series includes four (4) DSP sensors with measurement ranges from 6.35 to 50 mm. Pair two 1200 series laser sensors together for thickness measurements or groups several together to make a web monitoring system. This laser sensor has been successfully used to measure production of lumber, metals, and rubber in line under production conditions and has also been used to measure parts on stationary inspection benches.

This is our lowest cost and most compact line of precision laser triangulation laser.

Call 866-9945-5742 or email: [email protected] for pricing & more information.

Laser Displacement Sensor 1200 Series Features:

- 6.35 to 50.8mm measurement ranges

- 0.0019mm resolution on 6.35mm measurement range

- 1250Hz maximum measurement frequency

- Complete system in one housing

- Class 2 laser for plant safety

- Digital/analog outputs with serial communications

- Rugged design

- On board processing of data

- Lowest cost midrange sensor with moderate accuracy

- Small footprint

In-process thickness and distance measurements. For boards, fiberboards and plasterboards we offer turn key systems to measure thickness, width, edge and edge and thickness profiles. The measurements are made right on the transport mechanism. All the measurements are processed by the system's PC. Results are tabulated and graphed for easy operator analysis. All parameters including edge, width and thickness tolerances can be used for alarm conditions.

For the manufacturing environment, we provide a wide variety of distance measuring lasers to meet the numerous needs for non contact displacement and thickness measurements. All sensors incorporate the latest in Digital Signal Processing (DSP) technology which significantly reduces the laser speckle problem enabling them to easily measure materials ranging from black rubber to shiny steel. Even hot materials can be measured with the DSP series.

All of our DSP sensors are a complete system in one rugged housing. A separate controller is not required. Sensor outputs

can include, analog, RS 232, RS 485 Profibus and Ethernet. In addition tolerance alarms are available.

1200 series sensor for measurements on materials such as metals, rubber, plastic and wood products.

Measurement Types

- Thickness and displacement

- Profile a moving surface

- Seam or defect detection

- Level detection

- Height

- Flatness

- Radial and lateral runout

- Alignment and vibration

- Product sizing

- Lobing and circular and lateral runout

Typical Applications

- Web thickness measurements of all materials

- OSB board, plywood, veneer, and gypsum board

- Paper roll mills for width and diameter

- Steel mills for width, length and thickness

- Overhead crane positioning

- Elevator positioning

- Level measuring in silos

- Altitude measurements

- All types of material handling

DLS series sensors for very long distance measurments to a high degee of accuracy.