General:

Machine type: coordinate measuring machine with CT device

Probing system: compact X-ray sensor Modes of operation: CNC control Measuring software: WinWerth® Operating system: MS Windows

Measuring Ranges:

Max. part dimensions for tomography***

– For “in the image“- measurements): from L = 93 mm (3.7“), Ø = 120 mm (4.7“) to L = 145 mm (5.7“), Ø = 192 mm (7.6“)

– With optional raster tomography: from L = 94 mm (3.7“), Ø = 201 mm (7.9“) to L = 112 mm (4.4“), Ø = 280 mm (11“)

Max. distance X-ray source – detector FDD = 500 mm (19.7“)

Dimensions and Masses:

Installation area (without instrument table):

Depth: 674 mm (26.5“)

Width: 1300 mm (51.2“)

Height: 1370 mm (53.9“)

Machine weight: 880 kg (1940 Ibs.)

Workpiece weight: 10 kg (22 Ibs.)

– For specified Error MPE: 2 kg (4.4 Ibs.)

Maximum Permissible Error MPE*

For advanced laboratory conditions

For CT Sensor1)

P: 5 μm

E: (5+L/75) μm

SD3): (4+L/100) μm

No air conditioning required

For CT Sensor2)

P: 7.5 μm

E: (7.5+L/50) μm

(Where L = measuring length in mm comparable to ISO 10360 and VDI/VDE 2617)

Additional Performance Data:

Resolution rotary axis: 0,36“

X-Ray Components:

– X-Ray Source:

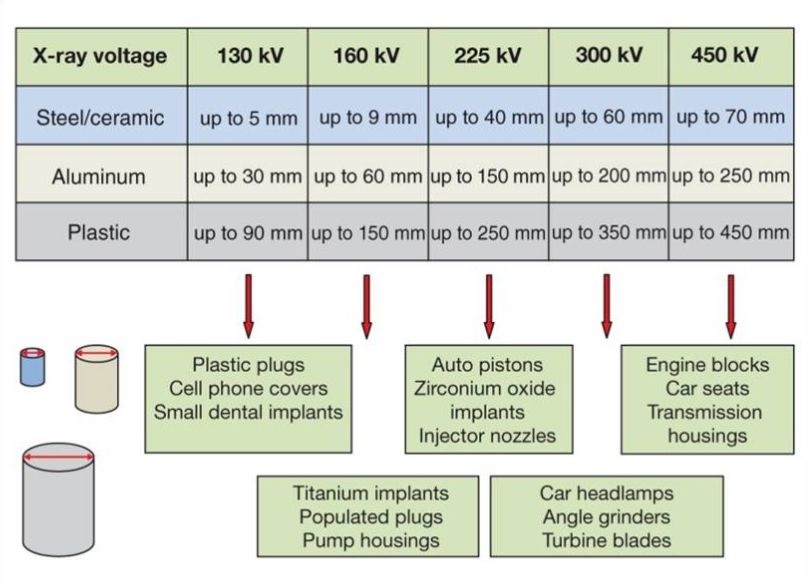

Macro focus monoblock tube: 160 kV / 500 W

– Detector:

– Surface area: from 140×110 mm2 to 287×223 mm2

– Number of pixels: from (2800×2200) pixel to (5800×4500) pixel

– Pixel center distance: 50 μm to 75 μm

Supply Data**:

Voltage measuring machine: 230 V (115 V) ±10%

Frequency: 50–60 Hz

Power: max. 2000 VA

Air pressure: 5.5–10 bar

Air consumption: 3000 Nl/h

Permissible Environmental

Conditions:

Environmental air: Humidity 40%–70% rel. hum., oil free

Air contamination: max. 0.05 mg/m3

Operating temperature: 10–35 °C (50–95 °F)