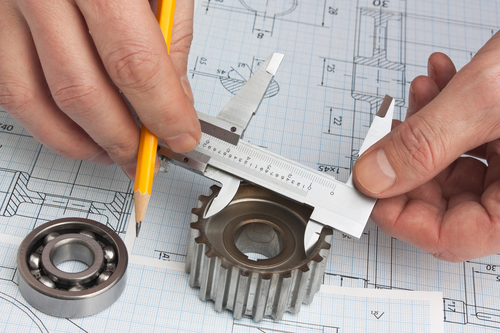

Measuring tasks should be carried out with accuracy and precision in order to achieve top-notch production related quality assurance. In addition to that, the measuring instrument should have enough flexibility to give accurate results. If a measuring device is employed for a large number of applications instead of just measuring tasks, expensive devices can be saved.

Are You Well-Equipped To Handle All Measuring Tasks

31

Mar