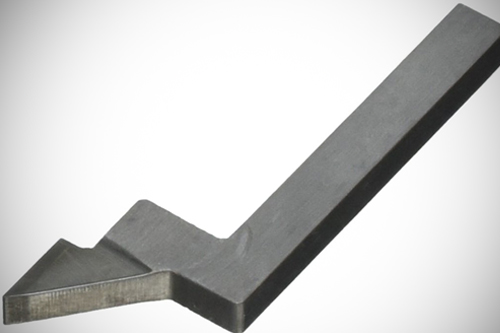

After layout work became a fundamental requirement, long-range height measurements are now common in a wide range of large manufacturing plants, small machine shops, and even among home hobbyists. With that in mind, a scribing height gage is a device used to determine the height of objects, allowing operators to mark items that need to be worked on (e.g. machined). The typical set-up of a height gage is comprised of a dial indicator, a scriber (often used in metalworking processes to mark lines on workpieces), a surface gage, and a surface plate. All in all, height gages are great for measuring and/or preparing an emergency replacement part, prototype piece, etc.

Sizes and Models

Scribing height gages are available in an array of sizes, ranging from 72 inches. They typically incorporate a motor or rapid hand crank to enable speed positioning. In addition, a scribing attachment makes positioning to 0.001 mm possible. There are various models of scribing height gages that incorporate quick-adjusting release features, allowing the scribing point to move directly to the desired reading. Some may also have a built-in, fine-adjustment mechanism that allows the user to “zero in” with ease.

You Can Replace the Gage’s Scriber Point

One of the best things about these height gages is that the scriber point can be replaced. This is a useful feature because the scribing point will become worn at some point; replacing the scriber is sometimes easier than sharpening it again. That’s not all. Modern systems allow operators to substitute the replaceable points with other adapters and tips, further expanding the capabilities of the height gage.

Handy Adapters

It is now common for scribing height gages to feature adapters. They can be fitted with test indicators and are highly recommended because they have a higher resolution than digital height gages. This is great if you need to turn your height gage into a high-resolution transfer stand.

With this set-up, you can inspect out-of-square deviations. You may need to use the reference pads that are built into the base and some additional fixturing. Next, you may need to turn the stand and the test indicator into a basic perpendicularity gage. Don’t forget to move up the part and zero in on its base.

Alternatively, you can set the test indicator to zero with the aid of a master or gage block before sliding it along the surface plate to the part. You can then proceed to compare the part to the reference standard.

Hassle-Free Procedure

Scribing height gages are easy to use; below are some basic steps you can follow:

- Place the workpiece on the surface plate

- Bring the scribing pointer to the reference surface

- Ensure that the pointer is flush to the surface plate (look out for angled or warped conditions)

- Once it’s confirmed that the contact is flush with the table, start zeroing the height gage

- Now you can start scribing your workpiece!

With today’s digital height gages, you may even skip these steps if it comes with a single-keystroke function. They make it easier to measure point-to-point dimensions and allow operators to read any changes in height at various locations.