Calipers are highly versatile tools designed for a wide array of distance measurements. These tools allow you to measure inside diameters and outside diameters with exceptional ease. Although micrometers provide more accuracy, they have limitations in terms of measurement range. With that, an average caliper can span from two inches to four feet.

Today, there are three basic types of calipers, including vernier, dial, and digital. Vernier variants are the original design, dial variants are second-generation calipers, digital calipers are the latest forms of calipers and have been used in shopfloor environment for more than two decades.

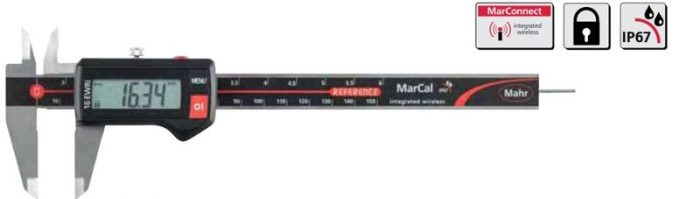

Unlike dial calipers, digital calipers do not feature gear systems, pinions, or racks. These differences make them more shock-proof. In addition, digital calipers can easily convert from inches to mm and vice versa. If you are looking for a digital wireless caliper, you should consider Mahr Federal 16 EWRi Digital Wireless Calipers. Let’s find out more about this amazing product in this product spotlight!