Everyone knows that it is important to check the quality of shiny coatings, measure surfaces that are about to be coated, and more. What’s more, it allows coating chemical manufacturers, electroplating firms, plastic parts producers, etc., to safely document and assess surfaces. The question now is how you are going to do that. What methods should you use for testing and quality control for plastic coatings? Let’s find out more!

Using Professional Evaluation Software

If you are currently using computer-controlled optical measuring devices, you should check if they come with any in-house software. By using professional evaluation software, you can easily get highly precise 2D and 3D surface analyses and measured value evaluations of plastic coatings.

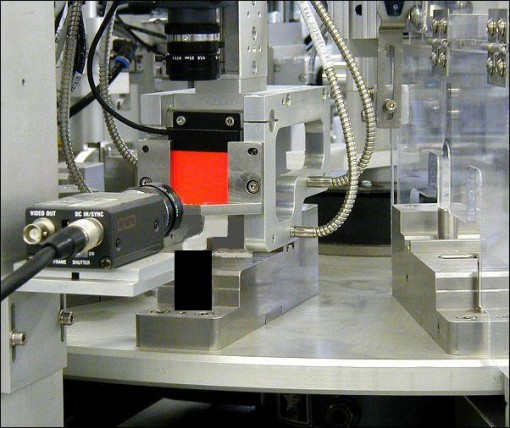

Carrying Out an Optical Measurement Test

The dimensions of a plastic coating’s microstructure and the magnitude of the light wavelength can generate reflections that irritate the sensors of conventional microscopes, and that leads to measurement errors. If you are testing the optimum roughness coated plastic surfaces, you should use an optical measurement instruments that measure identical surfaces with varying physical principles. This method is more practical as it provides a realistic assessment of the surface.

Measuring the Surface Structure of a Base Material

Professionals, who are working in the electroplating industry or need to manufacture coating chemicals for plastics, often need to control the behavior of their chemicals and how they would react to the surfaces of base materials. Since the surface finish of a coated plastic surface depends on the surface structure of the base material, you must remember to test it in terms of its quality.

Measuring Coated Plastic Surfaces

After the application of a metallic layer on a plastic surface, the surface has to be re-evaluated and measured again to determine its smoothness, and whether it is adequately homogeneous to be perceived as a “good-looking” metal surface by the naked eye. So what should one be looking for? On metallic surfaces, there are nanometers that can interfere with the surface structures. These nanometers must be analyzed and recognized. A good way to identify these nanometers is to use the interferometric measurement method.

Checking Defined Roughness

Another important measurement task to undertake is to check the defined roughness of a plastic surface before it receives its coating. If you are manufacturing coating chemicals, you need to make sure if the coating materials can compensate for any irregularities present on the plastic surface. This is also essential to ensure that the human eye perceives a homogeneous surface. In this case, you may need to utilize extensive measuring technology that work in the nanometer range.

Evaluating in the Subnanometer Range

Today, metal surfaces abound and are used for a wide range of applications. However, you should be aware that they are often metallic coated plastics. Some examples include the silver-looking surfaces of a cell phone, metallic glossy ball-point pens, chrome trim strips of car windows, and more. With that, you need to assess the said surface and pin point any irregularities in the subnanometer range to make sure those glossy coatings enhance the looks of your plastic coatings. Getting highly accurate quality assurance of those coated surfaces will do the trick.