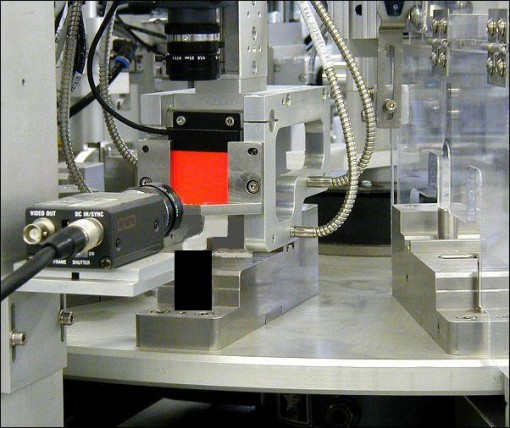

Optical comparators are used to magnify an image of a part to gather a tremendous amount of information about that particular part in a short time. For those who are not very familiar with these kinds of machines, optical comparators are measurement tools that magnify images onto a glass screen using mirrors, lenses, and illumination sources for the purpose of making two dimension measurements.

Optical comparators have been used for more than five decades and they still remain a cost-effective and versatile technology for monitoring the quality and processes of a wide range of manufactured parts. Over the years, optical comparators have evolved into full-featured equipment that uses modern optical, electrical and mechanical technology to maximize cost savings and minimize inspection time. So, why should you invest in optical comparators?