CT scanning technology can inspect the interior structure of the injection forged, molded or cast parts made from composites, polymers, plastic and metal products, without causing any damage to the objects. Seeing through a solid object was once a fantasy, but the technology of computed tomography imaging has made it possible. It is now being used in various industrial metrology settings for packaging integrity and product evaluation.

- Air Gages

- Bore gages

- Calipers

- Calibration Equipment

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

- Height Gages

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS & CALIPERS

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Metrology World

Should You Purchase A Video Inspection System Or Microscope?

It can be a daunting task to choose the right inspection system for your application. Three types of inspection systems are generally employed for industrial applications. Let us a take a look at each one of them, along with their merits and demerits.

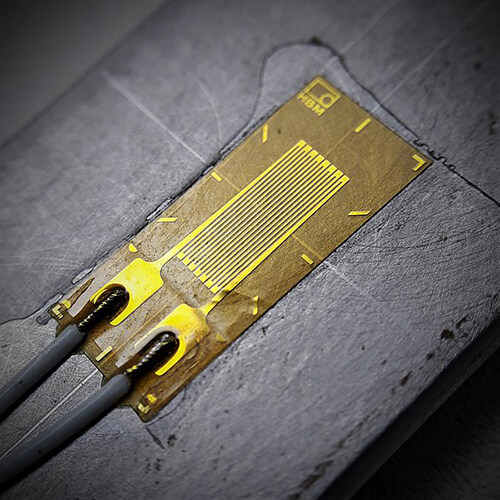

What You Need To Know About Strain Measurement Errors

Strain measurement is capable of resolving one PPM (one part in a million) or more. This is because of the exacting controls and standards under which each strain gage is manufactured. Some of the principal measurement errors arise from the manner in which the strain gage sensor is installed and measurement is taken. Let us take a look at some of these.

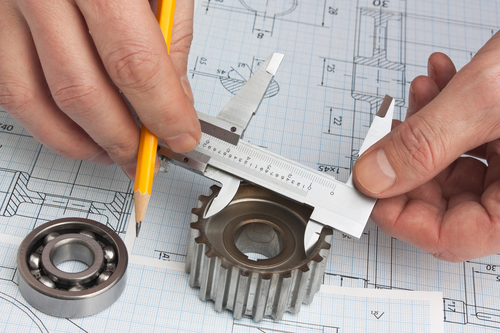

Essential Tools To Have For CNC Machine Shop Owners

The science of measurement is known as metrology and the application of its principles plays a pivotal role throughout production process in CNC machining. This is done to make sure that each and every part is machined to the right shape and size. Measuring dimensions of a CNC machine part with tight tolerances can be difficult. Depending on the quality, quantity and the type of work they do, there are distinct set of metrology tools in every CNC machine shop. Here are a few you should have, if you are an owner.

Are You Well-Equipped To Handle All Measuring Tasks

Measuring tasks should be carried out with accuracy and precision in order to achieve top-notch production related quality assurance. In addition to that, the measuring instrument should have enough flexibility to give accurate results. If a measuring device is employed for a large number of applications instead of just measuring tasks, expensive devices can be saved.

Understanding The Evolution Of Tolerances In The Aerospace And Automotive Industries

Times have changed. The same goes for manufactured parts produced by the aerospace and automotive industries. Their complexity grows each year and that is why tolerances that must meet metrology and quality control standards are now increasingly optimized and sophisticated. What’s more, a growing number of clients are requesting their suppliers to ensure their own compliance control aka GD&T is up to required standards. Compliance control was previously a mere input control sample designed to assess a lot’s compliance.

Purchasing The Right Coordinate Measuring Machine For Your Needs

A CMM or coordinate measuring machine plays a very important role not just in the world of quality control procedures but also when it comes to parts inspection. Since quality control and inspection are two of the determining factors as to whether a product will meet customer requirements or not, tools like the CMM will be very much essential in the process. If you have finally decided to buy a CMM to help you with then here are tips on how you can make sure you will be able to buy one that suits your needs.

Learn How A Complex Plastic Part Is Reverse Engineered

Today’s manufacturing, quality and design engineers often need just two gears to get their tasks done; forward and reverse. Moving forward is the best strategy, but it only looks good on paper. Things can go astray at any point.

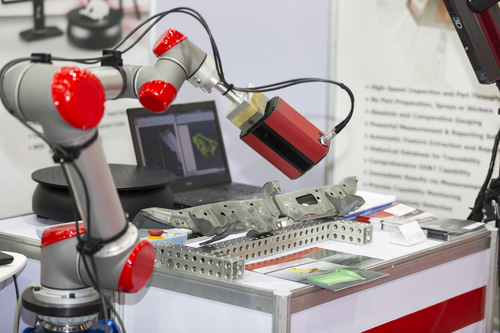

Deciding Which Degree Of Automation You Prefer On Your Manufacturing Floor

To automate a process, technical feasibility is a necessary prerequisite. This is the most important factor about automation to consider when automation is taken into account. Another precondition is the cost for development and deployment of both the software and hardware for automation. Labor cost and supply-demand dynamics also play an important role. The most important component in successful deployment over a period of time is the effort in adapting technology with human capital. With transformation of each individual workflow, every job will be changed, eventually. This requires change in skills as well as mind-sets.

What’s The Difference Between Precision And Accuracy

When taking data measurements, precision and accuracy are two most important factors to consider. Both of them reflect how close we are to getting an actual value. However, there is a slight difference between the two. Precision gives the reproducibility of the measurements, even if they are nowhere near to the accepted value. Accuracy gives a number close to that of accepted or known value. It’s like hitting a bullseye. Measurements which are both accurate and precise are very near to actual values, and can be repeated.

Continue reading →

Universal Metrology Automation Is Now Possible With Metrology Integrators

Universal metrology automation solutions can quickly authenticate dimensional conformance on anything from sub-millimeter solder joints to precision-machined components, molded plastics and large aerospace castings. Coupled with a metrology integrator, it can offer countless system configurations by using streamline automation software to link dissimilar software and hardware with a general interface, helping to make intelligent decisions.

Continue reading →

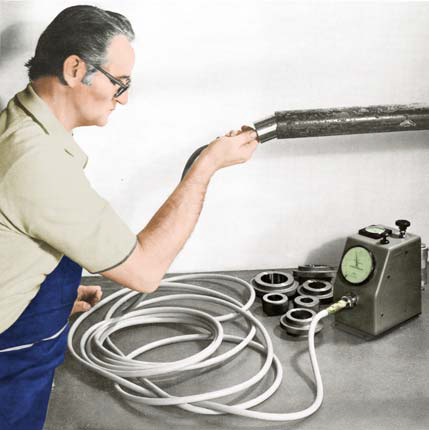

Understanding How Air Gaging Works

Air gaging works according to a law of physics that states pressure and flow are directly proportionate to clearance, which then react inversely to each other. This means that when clearance decreases, air flow and air pressure also decrease and increase respectively. When clearance increases, air flow and air pressure will increase and decrease proportionately. This is usually accomplished by regulating air flow via some sort of restriction. Two common options include a jeweled orifice or a needle valve. With that in mind, one will be able to increase back pressure and reduce air flow by bringing the workpiece (the obstruction) closer to the nozzle. If the nozzle becomes completely obstructed, there will be zero flow. Regulated air and back pressure will also be at the same level.

Why The Aerospace Manufacturing Industry Can Benefit From Automated Scanning Solutions

When it comes to advanced aerospace manufacturing, the industry can be a competitive one. Driving innovation has always been one of the key contributors to the longevity of the industry. A wide variety of aerospace research organizations out there that are involved in the testing and designing solutions to help develop aircraft parts more efficiently. As the industry continues to move forward, determining how to leverage scanning solutions, which are automated, to improve throughput and speed are of utmost importance.

Due to a large production volume, a wide variety of automobile manufacturing companies have embraced automation. Aircraft manufacturers, on the other hand, are low-volume producers and that’s why the adoption of automation technologies was delayed. However, the trend is changing. More aerospace organizations have started to make use of automation in lower-volume production markets. Let’s find out more on how the aerospace industry can benefit from automated scanning solutions.

Understanding The Different Types Of Contact And Non-Contact Inspection Systems

Today there is a growing trend towards miniaturization especially in the electronics, medical device and computer industries. If you are involved in one of these industries, you need to ask yourself which inspection system best meets your requirements. Between the contact and noncontact inspection systems, which type should you choose? The resurgence of match-fitting and selective assembly practices which depend on more precise measurement data, makes the question as timely as ever.

What Can Optical Comparators Do For You?

Optical comparators are used to magnify an image of a part to gather a tremendous amount of information about that particular part in a short time. For those who are not very familiar with these kinds of machines, optical comparators are measurement tools that magnify images onto a glass screen using mirrors, lenses, and illumination sources for the purpose of making two dimension measurements.

Optical comparators have been used for more than five decades and they still remain a cost-effective and versatile technology for monitoring the quality and processes of a wide range of manufactured parts. Over the years, optical comparators have evolved into full-featured equipment that uses modern optical, electrical and mechanical technology to maximize cost savings and minimize inspection time. So, why should you invest in optical comparators?