Digital height gages can, with their long range of motion, be looked at as a sort of giant caliper. They do, however, possess a heightened level of accuracy because they are, as a benchtop gaging system, far more sophisticated. Reliably and quickly, a wide range of measuring tests can be performed by these extremely versatile gages. What’s more, they are easy to maintain, to use, and to set up.

- Air Gages

- Bore gages

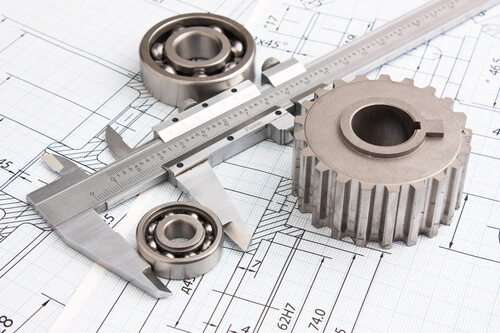

- Calipers

- Calibration Equipment

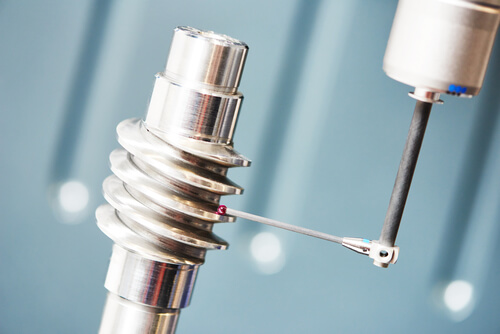

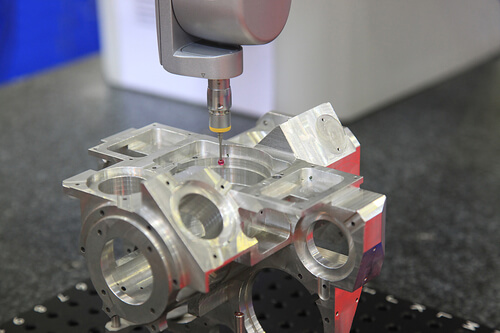

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- Height Gages

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS

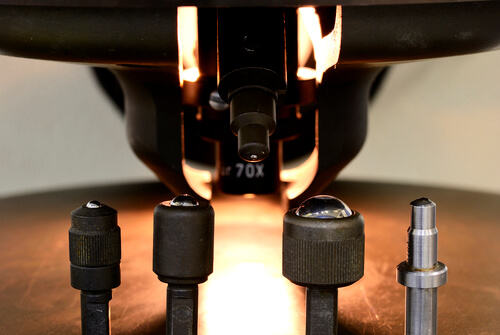

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Metrology World

How Will Metrology Evolve In The Near Future?

The last 25-30 years have seen many advances in computerization, software applications and equipment use. Therefore, it is no surprise that metrology continues to benefit from these changes. With the advancement of 3D scanners and CMM laser scanners, the precision world of metrology during the process of manufacturing will continue to improve, as will the ability to ensure tighter controls over quality and inspection. There will be many more devices produced that will increase productivity not only in the manufacturing domain, but also in the automation industry.

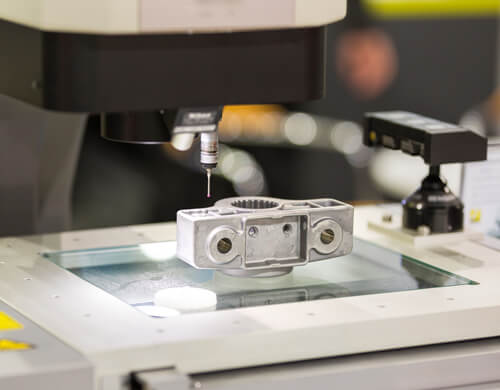

CMM Laser Scanners Can Reduce Inspection Times

There are many parts that need precision analysis and checking. Quality is of paramount importance. However, until recently there were few procedures that could give such excellent results in terms of speed, accuracy and reliability. CMM laser scanners (or coordinate measuring machines) can provide all of these essential components in a fraction of the time previously required to obtain the same results.

Can 3D Scanning Tech Be Used For Roller Coaster Accident Prevention And Maintenance?

Most people have experienced the thrill of a fairground ride or roller coaster. The fear and adrenaline are something that is hard to replicate in any other way. So, when we consider the mechanical and engineering design of the ride, how can we be sure it is as safe as it can possibly be? In the past, the individual components and design has been soundly tested to ensure that the ride is structurally sound, and many tests and simulations are invented and applied to try to account for any eventuality. In addition, they are routinely tested every single day before use to ensure there is no mechanical fault or wear. So, how can 3D scanning help?

Can Artificial Intelligence Enhance Machine Vision System Capabilities?

We have been using robotic energy and services for years for a variety of manufacturing practices However, as artificial intelligence continues to improve, we are starting to tap into its capabilities to use it in a more productive way. The benefit of learning-based image analysis is a greater inspection capability and machine vision with less errors or flaws than human judgement. Smoother and more accurate operations lead to an increase in productivity and more profit.

What You Need To Know About Starrett’s New Digital Force Testers

L.S. Starrett Co. recently introduced a new line of motorized digital test frames designed for a great array of force-testing, in-situ manufacturing, high-volume, and basic applications. These applications included friction, shear, flexural cyclic, compression, and tension. The latest series of products is called Starrett FMM digital force testers. They are also part of Starrett’s brand new L1 line of computer-based, entry-level, force measurement solutions. These testers are optimized for quality control testing and production. L1 systems feature an innovative architecture and are versatile enough to provide reliable and repeatable operation. Let’s find out more about Starrett’s new digital force testers:

An Introduction To FARO’s CAM2 2018 3D Measurement Software Platform

FARO is a full-service, portable coordinate measuring solution provider. They are an advocate of high-accuracy. The company has announced the recent release of their CAM2 2018 software platform. The platform is specifically designed to help users realize the highest level and value of performance with all FARO metrology products. In addition, that realization spreads across metal-fabrication, machine tools, aerospace, and automotive industries. Let’s find out more about FARO and its new 3D measurement software platform.

Data Integrity Pitfalls In Calibration Procedures

Data integrity is the assurance of the accuracy, maintenance of and consistency of the data. The concept of data integrity has been applied for many years. However, it has become more acute recently since auditors are paying more attention to data integrity than before. The FDA, EMA and other regulatory bodies have also set new regulation guidelines that need to be adhered to.

Understanding The Roughness Parameter Called “Max”

A quick glance at a finished surface will make you think it looks perfect. However, imperfections are bound to be there, and they may come in the form of valleys and hills, varying in both spacing and height. Roughness as that is called, exists in the form of a succession of minute irregularities. This may be caused by its own finishing process, such as the utilization of a single point tool. Surface roughness tends to be both directional and uniformly spaced. If surface roughness was a result of cylindrical or straight grinding, the roughness of the surface tends to be irregularly spaced.

Understanding The Importance Of Metrology In Our Daily Lives

Accessing knowledge can never be possible without a number as well as a standard of measurement which produces the said number. It gets more interesting with the fact that both the number and the measurement cannot exist without units. This is more or less the role of metrology. It stands out not only as an individual discipline of physical sciences but also the base of daily activities. It is in fact, safe to say that people use metrology daily without realizing it. In light of this, measurement is therefore, an economic, social and scientific necessity. Understanding this makes it easy for one to understand the importance of metrology in our daily lives.

What You Need To Know About Coating Thickness Gages

Also known by the name of paint meter, a coating thickness gauge is used for the measurement of dry film thickness. This parameter is possibly the most important one in a wide range of industrial applications, since it has a significant impact on cost, quality and coating process. These measurements can be employed to estimate the life expectancy of coating, the performance and appearance of product, and to guarantee agreement with a host of industry standards.

Why You Should Update Your Calibration Systems

A majority of companies in the process industries are looking to update its calibration systems and process. There are plenty of reasons why there’s a need of upgrading a calibration system. Updating the process basically implies work procedures and systems for managing, documenting and performing calibration of process instruments. There is an obvious reason behind any change, and most probably, it is the issues or challenges in the present way of doing things. Let us take a deeper insight into some of the common problems that may incite process changes.

Little Known Facts About Precision Measurement Tools

It is certainly surprising that some technicians know little about the precision measurement tools they use on a daily basis. In some cases, there may be a lack of resources to give accurate descriptions about what these tools are and what they are really designed for. This lack of knowledge may lead those technicians to buy and use the wrong tools for specific jobs.

Understanding The Different Types Of Hardness Tests

The ability of a material to resist permanent indentation is known as hardness. It is an empirical test, rather than material property. In order to define different hardness values for the same piece of material, there are several types of hardness tests. The outcome of each test should have a label identifying the method used, as it is dependent on it. There is no intrinsic significance of hardness value or number, hence it cannot be used directly like tensile test value. The value is only useful for comparing different treatments or materials.

Understanding Alignment, Balancing, And Vibration In The World Of Metrology

The world of industrial maintenance is hectic, demanding and intensive. Even when working in the world of metrology, it can be hard to understand the differences between alignment, balancing and vibration. In this post, we will provide you an in-depth overview of each term and what role they play to ensure the health of your equipment.