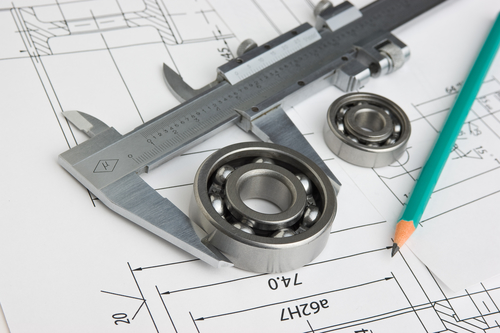

Calipers have been used for hundreds of years in one form or another. They are used to take basic measurements, and they are the one tool that many self-respecting carpenters cannot do without. They are also used by engineering firms to help with inspection. Today, there are a range of different types of calipers. These are: wireless, Vernier, electronic and digital. Calipers give a precise measurement but mastering them is an essential skill that needs to be acquired to ensure you get the most accurate measurement.

Master The Use Of Calipers

03

Jul