Flatness Measurement Gage

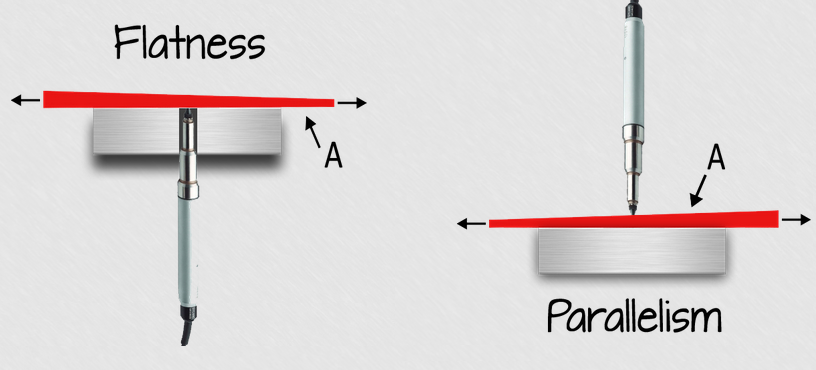

The inspection of the part is made by simply moving it over the probe and reading flatness variations directly on the readout. The probe is mounted thru the bottom of the surface plate. Either contact or non contact measurement can be made using an air probe or jet probe set in the plate and positioned to measure flatness. An indicator can also be mounted to check thickness

Flatness gage specifications: Surface plate of black Granite, typical 12″ x 12″ x 4″ (inspection grade A). Three point support provides accuracy to 50μ” Other plate sizes and accuracies are available.

For large parts that are too large to move over a surface plate the probe can be mounted into a serrated plate that has been lapped flat. This assembly is moved over the part and read out on the air gage readout.

Call 866-9945-5742 or email: [email protected] for more information.

Read More