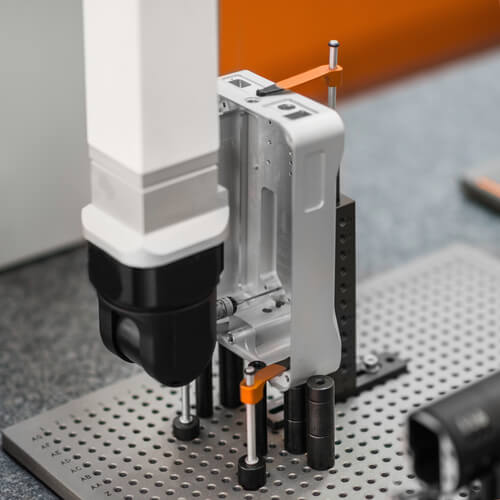

The most delicate and important inspections are dedicated to coordinate measuring machines (CMMs). CMMs for quality control are a common choice for measuring complex, delicate parts. However, just like other aspects in manufacturing, there are significant costs and time one has to consider. Let’s have a closer look into the time and costs required to operate a CMM.

How To Save Time And Money When Using CMMs For Quality Control

21

Dec