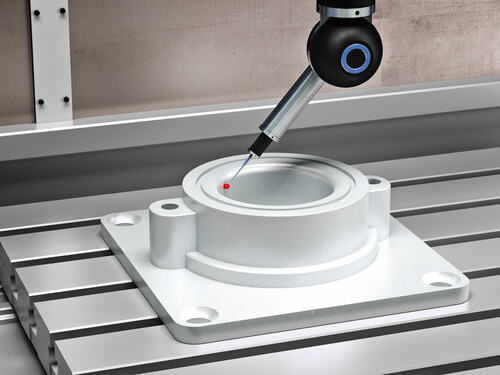

Coordinate measuring machines, also known as CMMs, are crucial pieces of equipment in the world of parts inspection and quality control. These are commonly used in carrying out inspections in the metrology industry and are very much needed in both the production floor and metrology lab. Since these machines are very popular, they take up to much work load considering the fact that they are not the fastest moving machines within the lab. The good news is you can easily unload these machines so that you can speed up the manufacturing process. Here is what you should do.

Tips For Unloading Your Coordinate Measuring Machines

15

Jun