To ensure you capture accurate data and calculations, it is essential that the workholding solution you use is up to the job. Some inferior or cheaper workholding equipment may not be able to withstand the pressure put on them during manufacturing at high speeds. There are many different solutions available, including a bespoke or customized workholder.

Consider The Workpiece

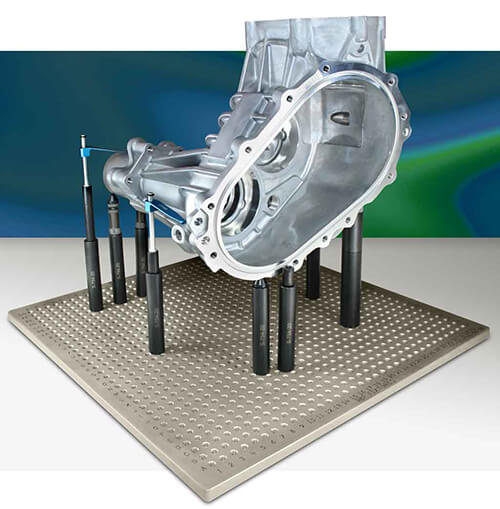

The first thing you need to consider when deciding what would be the most suitable workholding solution is the difficulty of the workpiece. If you have something that is thin but needs to be held very firmly to allow high torque pressure, then you would need to consider a solution that allows you to spread the clamp force over as large an area as possible. This will allow the workable piece to remain as rigid as possible, allowing more accurate shaping, grinding or inspection.

Work In The Best Environment Possible

The environment where the work takes place can play a huge part in the procedure. Ensure that all equipment is kept clean and dust-free and debris is not allowed to build up either around the workplace or on any of the tools used. If a workholding clamp has a build-up of debris, then this can affect how the part is held, which ultimately impacts the accuracy outcome of the procedure. Also, try to ensure the environment is kept at the same temperature as extremes of temperature can affect the data collection process, as metal changes the way it performs in different temperatures.

How High Is The Volume Of Work Required?

It is important that the workholding unit is able to do its job all the time. Accuracy is of paramount importance, and therefore when choosing the correct clamp for the job you should pay attention to the volume of work that it will be required to do. Choosing a unit that requires very little maintenance as well as maintaining a high degree of accuracy throughout its life is essential.

Mechanical Or Hydraulic Workholding Solutions?

There is a lot to be said for each of these types, so it really depends on the volume of work it is required for, as well as the difficulty of the part you are manufacturing. A hydraulic solution may be more practical if you are pressed for space for a particularly challenging piece or need extremely high accuracy. However, a drawback with a hydraulic solution is that once an issue arises with them, you are likely to need to replace the whole unit. When using a mechanical workholding unit, if any issues arise you would only need to replace the broken part.

Consider Your Future Needs

When considering which workholding solution you need, you should consider any future expansion as well as your current needs. This will ensure that any changes in the design of the item being manufactured will not present you with a challenging solution further down the line. Choosing a clamping unit that has the capabilities to change the diameter of the clamping area is a must and will negate any potential problems you may encounter with design change.