- Air Gages

- Bore gages

- Calipers

- Calibration Equipment

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- Height Gages

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Search Results for: concentricity

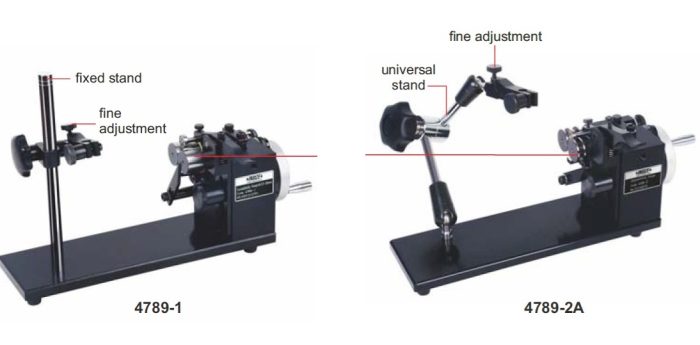

Concentricity Gage up to 25mm

Code Applicable diameter

4789-1 Ø3.5mm-25mm fixed stand, high accuracy inconvenient operation

4789-2 Ø1mm-25mm fixed stand, high accuracy inconvenient operation

4789-3 Ø1mm-25mm fixed stand, high accuracy inconvenient operation

4789-1A Ø1mm-25mm low accuracy, convenient operation

4789-2A Ø3.5mm-25mm low accuracy, convenient operation

4789-3A Ø1mm-25mm low accuracy, convenient operation

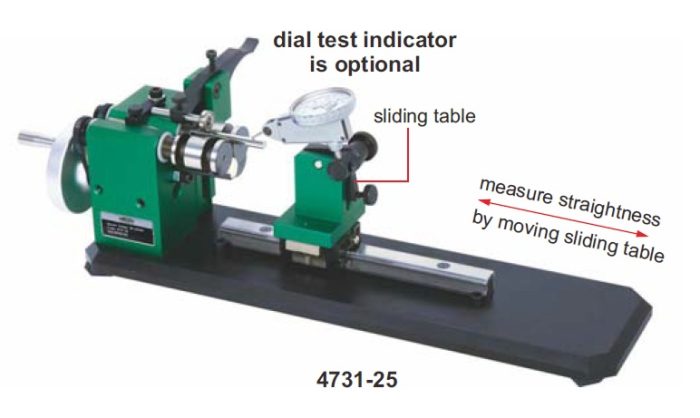

CONCENTRICITY GAGE WITH STRAIGHTNESS MEASUREMENT

INSIZE 4731-25 Diameter range 1-25mm length of workpiece 15-80mm

center height 70mm Maximum moving range of sliding table: 120mm

Optional accessory: dial test indicator

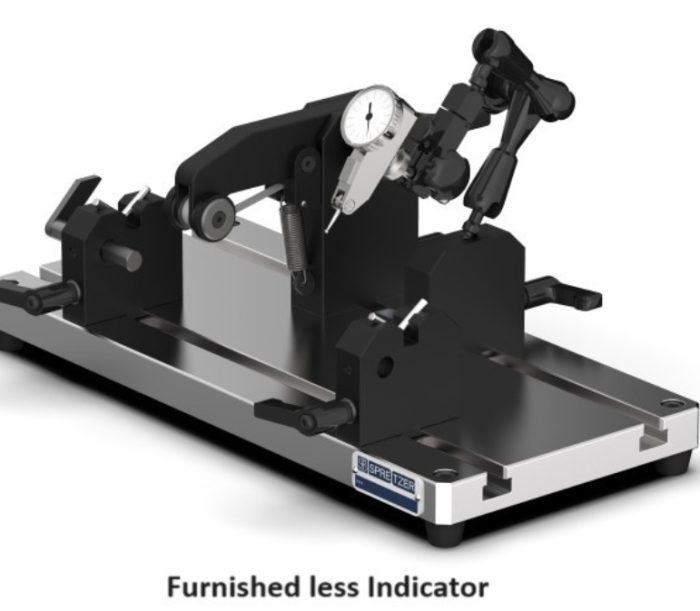

Spreitzer – RPGP 350 & 500 Concentricity Tester with VeeSupport

RPGP concentricity testing device is suitable for testing the concentricity of round workpieces with a diameter of up to 26 mm. The two support prisms with hard metal supports, the pressure or drive unit and the articulated arms with measuring device holders can be moved continuously on the base plate. One of the two support prisms is adjustable in height. This means that universal use is possible with different workpiece geometries. Thanks to the prism angle of 108°, polygon-like parts can also be tested.

- 2 Fixed Vee Supports with clamping levers or 1 Fixed & 1 Movable Vee Supports

- Universal stop that can be mounted precisely and at right angles to the prisms

- Slidable pressure or drive unit

- Articulated arm with Indicator Holde (Indicator not included)

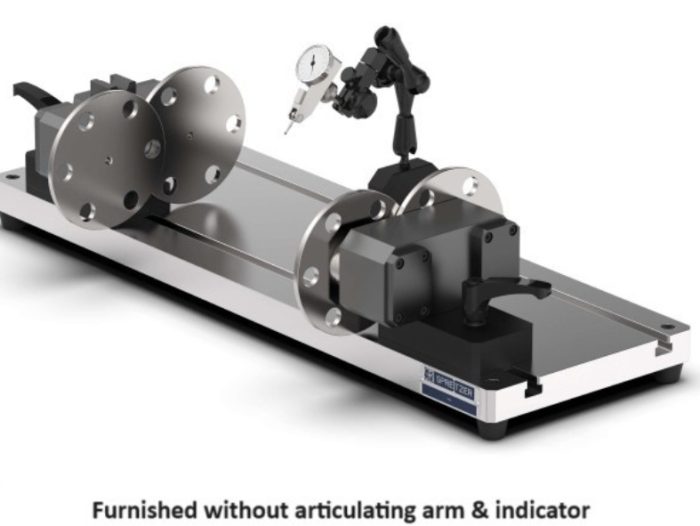

Spreitzer – Concentricity Gage with Roller Wheels

- The RPGR concentricity gage can be used for measuring the concentricity of round workpieces with a diameter up to 240 mm/9.5″.

- The two roller wheels are stepplessly movable on the T-Slot base plate.

- One of the roller wheels is height adjustable to compensate for different diameters of the workpiece.

- Workpieces with different geometries can be easily inspected.

- 2 Models Available.

Smart Spin Gage for Concentricity, Run Out and Perpindicularity

The NEW SMART SPIN Gage is designed to quickly measure cylindrical parts for outer diameter run-out, and part edge run-out (perpendicular to body diameter). To accommodate various size and style of parts, the device includes an adjustable backstop, overhead roll clamping, vertical and horizontal probe positioning. An integrated a STEPPER motor with specialized drive control hardware and software allows for precision

rotation and remote indicator RESET. These features allow for reliable results with proper setup for countless part shapes and sizes within a certain part size range. Two speeds are available for part testing: 10 and 20

RPM. we are able to offer an upgrade allowing for variable selection of the motor speed up to 40 rpm’s

Roto Round Concentricity Fixture

The rotoround is an adjustable fixture used to check concentricities, runout, and/or TIR of one or more surfaces to a basic diameter. Three precision bearings set the primary datum plane and support the weight of the part while 2 roller bearings mounted on the angled base define the circular datum. Indicators then contact the part as it is being rotated to determine various parameters

call 866-945-5742 or email [email protected] for more info

Universal Punch Series K Concentricity Gages Dual Indicator Gage

Universal Punch Series K Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST.

Standard Black Gage is guaranteed to be better than ≤ 4μm accuracy. Precision Gold Gage (-10 / -20 models only) is

guaranteed better than ≤ 2μm (.00008”) accuracy. For Precision Class add $250.00 to the base price.

K1 is side carrier

K2 is vertical carrier

Universal Punch Concentricity Gage Model H Shaft Gage Vertical Carrier

H Concentricity gage. Standard Shaft Gage / With End Support / Vertical Indicator Carrier for legnths up to 12″ or extended version for lengths up to 24″

Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST. Standard black gage is guaranteed to < or =4um accuracy. The Precision gold gage (-10 and -20 models) is guaranteed to < or = 8um accuracy (.00008″) accuracy

Universal Punch Model E Concentricity Gages Eccentric Checker Gage

Universal Punch Model E Concentricity Gages. Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST. Standard black gage is guaranteed to < or =4um accuracy. The Precision gold gage (-10 and -20 models) is guaranteed to < or = 8um accuracy (.00008″) accuracy

E-10 Standard Concentricity Gage Model ≤ 4µm (.00016) . Part diameters 1/8-1″

E-10P Precision Gold Concentricity Gage Model ≤ 2µm (.00008) Part diameters 1/8-1″

E-20 Standard Concentricity Gage Model ≤ 4µm (.00016) Part diameters 3/8″-2″

E-20P Precision Gold Concentricity Gage Model ≤ 2µm (.00008 )Part diameters 3/8″-2″

E-40 Standard Concentricity Gage Model ≤ 4µm (.00016) Part diameters 3/4-4″

E-40P Precision Gold Concentricity Gage Model ≤ 2µm (.00008) Part diameters 3/4-4″

Universal Punch Concentricity Gage J Series

Universal Punch Concentricity Gage J Series Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST. Standard black gage is guaranteed to < or =4um accuracy. The Precision gold gage (-10 and -20 models) is guaranteed to < or = 8um accuracy (.00008″) accuracy

Universal Concentricity Gage Model G- Side or Vertical Checker Gage

Universal Concentricity Gage Model G1. Side Checker Gage / With End Support / Side Carrier.

Universal Concentricity Gage Model G2. Vertical Checker Gage / With End Support / Vertical Carrier.

Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST. Standard black gage is guaranteed to < or =4um accuracy. The Precision gold gage (-10 and -20 models) is guaranteed to < or = 8um accuracy (.00008″) accuracy

Universal Punch Concentricity Gage Model F Recess Fastener Check Gage

Universal Punch Concentricity Gage Model F. Recess Fastener Gage / End Support / Recess Checker Carrier. Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST. Standard black gage is guaranteed to < or =4um accuracy. The Precision gold gage (-10 and -20 models) is guaranteed to < or = 8um accuracy (.00008″) accuracy

F-10 Recess Fastener Check Gage For part diameters 1/8-1″ (3-25mm)

F-20 Recess Fastener Check Gage For part diameters 3/8-2″ (10-50mm)

Universal Punch B-10, B20 & B40 Concentricity Gage

Universal Punch Concentricity Gages B Series with Full Plain Roller – Adjustable multi-position top arm yoke assembly. Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST. Standard black gage is guaranteed to < or =4um accuracy. The Precision gold gage (-10 and -20 models) is guaranteed to < or = 8um accuracy (.00008″) accuracy

Universal Punch Concentricity Gage Model A-10

A Series Basic Gage / Standard Carrier. Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST. Standard black gage is guaranteed to < or =4um accuracy. The Precision gold gage (-10 and -20 models) is guaranteed to < or = 8um accuracy (.00008″) accuracy

A-10 Concentricity Gage Basic Single Gage Part diameters 1/8-1″ / 3-25mm standard carrier. Part length up to 3″ .