- Air Gages

- Bore gages

- Calipers

- Calibration Equipment

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

- Height Gages

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS & CALIPERS

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Search Results for: concentricity

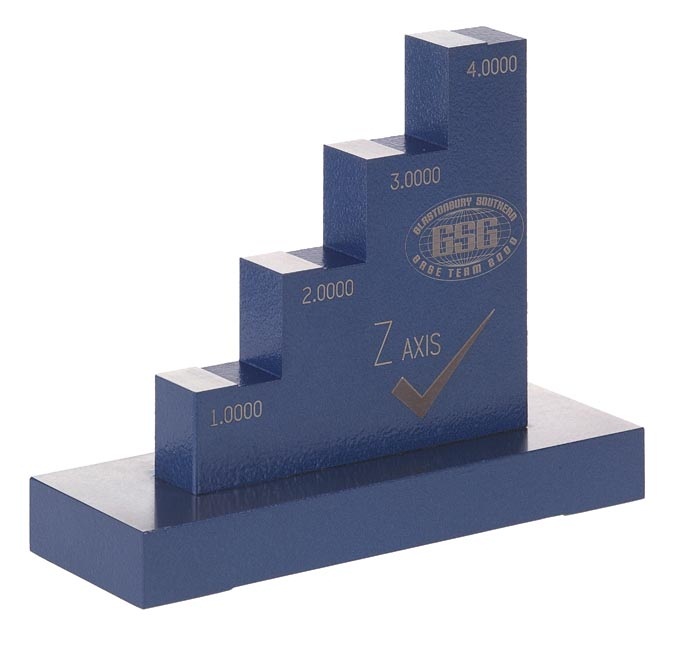

Glastonbury Z Axis Check

Glastonbury Southern Gage Master for calibrating the Z axis on your optical Coordinating Measuring Machine (CMM) quickly and accurately in just minutes.

All Z Axis Chek’s are supplied with calibration of four steps and engraved to the nearest .000010″ with complete traceability to NIST.

Supplied with certification & storage cases.

LX-1: Lapped base with mirror finish LX-1 +/-.00005

GX-1: Ground finish base for less reflection GX-1 +/-.0001

Master for calibrating the Z axis on your optical CMM. Certified to the nearest .00001 0″.Supplied with certification & storage cas es.All Z-Axis Cheks are 440c stainless steel

Mahr Federal MMQ 200 Roundness Measuring Machine

The Mahr Federal MMQ 200 is an automatic measuring machine for testing deviations of form For proving the quality of your products, the MarForm MMQ 200 assesses the deviations of form and position as per DIN/ISO 1101 and documents them.

Call: 866-945-5742 or email: [email protected] for more information.

Mahr Federal MarForm MMQ 100

The Mahr Federal MarForm MMQ 100 roundmess measuring machine offers superior accuracy in a rugged, shop floor hardened package.

In combination with the EasyForm Software it represents the perfect solution for simple yet powerful measuring tasks

The MarForm MMQ 100 form tester is the ideal solution for simple yet precise measuring tasks.

Accurate and fast measuring results

Reliable due to mechanical bearings

Portable due to light weight and compact dimensions

Fast computer‑assisted workpiece alignment

Digital encoder in Z and X sends the measuring position directly to the software

Suitable for use in workshops, no compressed air connection required

All in one PC is included

No keyboard or mouse required with all in one touchscreen computer

Call 866-945-5742 or email: [email protected] for more product information.

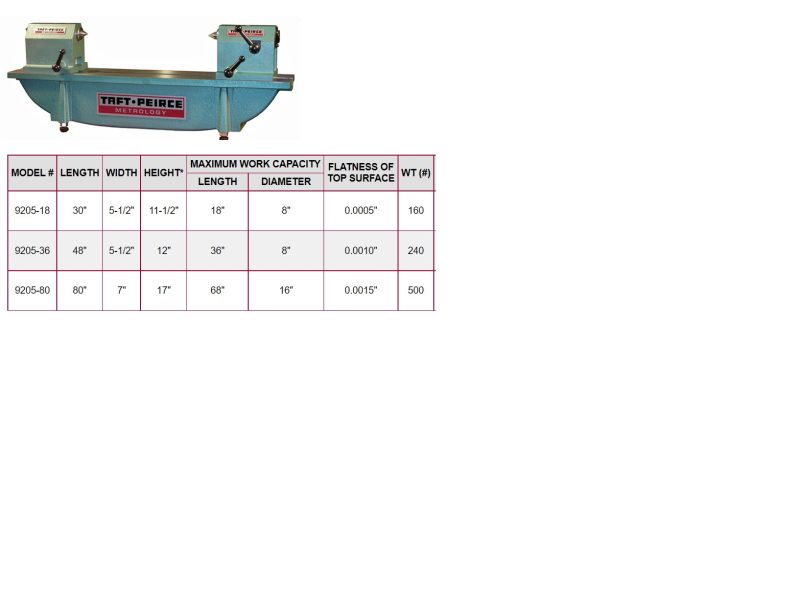

Mitutoyo 967 Bench Center

Mitutoyo Bench Center 967 series. Mitutoyo has made this obsolete. We can offer below as an alternative option.

Mahr Helio-Scope Optical Measuring System

Optical Measuring Instrument for turned parts with matrix camera for use in the production area.

Typical measuring tasks: Length, diameter, angle, radi, intersection line, axial run-out, run-out

Further measuring tasks:

Thread, distance, width of recesses, depth, diameter of recesses, roundness, taper, concentricity, coaxiality and much more.

Call 866-9945-5742 or email: [email protected] for pricing & more information.

Internal and External Thread Inspection

Internal thread inspection and External Thread Inspection Gages.

- PITCH (MINIMUM MATERIAL) DIAMETER

- TAPER AND OVALITY

- INCLUDED ANGLE

- UNEQUAL HALF-ANGLES

- MINOR DIAMETER

- MAJOR DIAMETER Concentricity between major and PD is checked by using inserts “C” and “J”. Major Diameter size, roundness and taper are checked by a pair of “C” inserts.

- FUNCTIONAL (MAXIMUM) MATERIAL DIAMETER

PITCH (MINIMUM MATERIAL) DIAMETER

Upper & lower fingers have tungsten carbide balls of “Best Wire Size”, and give a reading which excludes lead error but not angular errors. PD fingers can be used for right or left hand threads.

FUNCTIONAL (MAXIMUM MATERIAL) DIAMETER

Paired fingers “L” are helically ground for a single PD, pitch/lead combination which will measure the net effect of “all errors”.

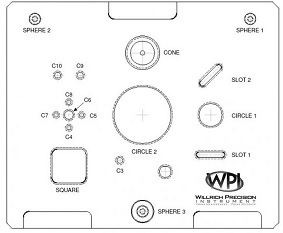

CMM Calibration Artifact

CMM Calibration Artifact

Our CMM Calibration Artifact is designed for use as an intermediate check with Coordinate Measuring Machines (CMMs) and includes an ISO-17025 accredited certification.

It is designed to provide added confidence in a CMM between annual calibrations. By performing an artifact calibration routine on a regular schedule, the accuracy of your CMM is monitored and allows you to be proactive if any “drift is discovered.

A variety of geometry types are included: circles, slots, widths, spheres, cone, etc.

Optionally, a CMM program in DMIS format is available for measuring the artifact. This ensures that the measurement routine is the same as the one used to certify the artifact.

Please call for price on the standard with the new GD&T included per below and MBD (Model based definition) model.

DMIS program as option (if you have DMIS Software on your CMM

Native CMM Programs option (Calypso, PCDMIS, MCOSMOS, etc.)

GD&T INCLUDED

- Perpendicularity

- Flatness

- True position

- Profile

- Perpendicularity

- Parallelism

Gen 1 CMM Artifacts have a variety of geometrical shapes to verify your CMM perfomance. Cicles, Slots,

Widths, Spheres, Cones, etc. GD&T includes Perpendicularity, Parralelism, Flatness, True Position,

Profile, Angularity,

Gen 2 has additonal features for higher level of analysis of CMM performance: Steps for Z, Roundness,

Cylindricity, Straightness, Runout, Angularity, Concentricity, and Radii.

All CMM Artifacts are made in USA and certified ISO 17025

- What is the accuracy of the features on the artifact? – The CMM Artifact is not made to a stated accuracy, The CMM Artifact is ISO 17025 certified on a coordinate measuring machine Our uncertainty for values on the report is approximately ±.00005” over 12”.

The actual measurements from the CMM Artifact from our certified coordinate measuring machine are reported. Our reported ACTUALS are for you to compare on your CMM - You get an artifact that allows you to track drift of machine in between calibrations. We certify this on a high accuracy scanning UISO 17025 lab CMM and provide inspection reports so you can watch your CMM potential drift in relation to our readings.

- Item is composed of the A-2 tool steel

- Step file is included in base price

Overall dimensions 10 x 12″

Call 866-945-5742 or email: [email protected] for more information.

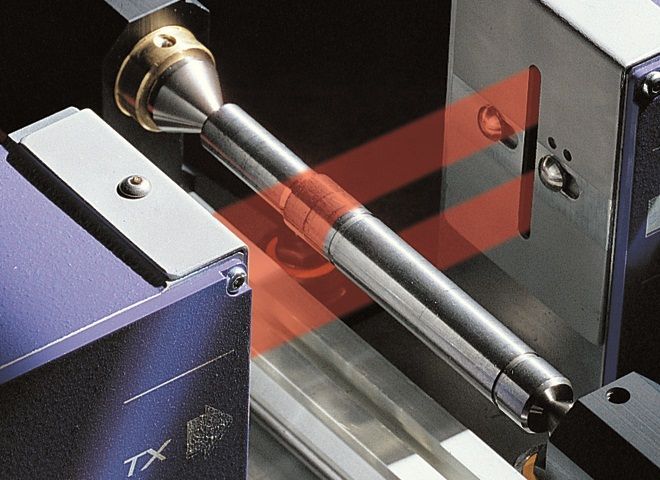

Fowler Sylvac Scan 52

When measuring becomes a breeze!

Place the workpiece on the SCAN machine, click the button and get all the values automatically and without prior programming. Perfectly integrated in the workshop, our SCAN 52 machines replace conventional

measuring systems including multi-gauging jigs.

Fowler-Sylvac’s machines are designed to measure round parts with diameters from 0.25 mm up to 50 mm (80 mm on request) and up to 500 mm long. Most of the cylindrical parts, such as aerospace and automotive shafts and components, connectors, dental screws and implants, hydraulics parts, metal packaging for food and cosmetics, rollers, turbines parts, CNC turned parts, etc. can be measured in a few seconds. Various thread types and features can be measured and analyzed with our machines.

MEASURING PRINCIPLE

All SYLVAC-SCAN incorporate high resolution CCD sensors that combine 2 x 7’000 elements linear arrays, with a patented 7.5° system, which would correspond to a camera with a resolution of 200 megapixels! As the part profile is projected, these sensors, which are capable of detecting the slightest changes at pixel level, act as a light sensitive rule.

The contour of the workpiece is reproduced in shadow image on the software and all the various elements shown can be measured in static (without part rotation) or in dynamic (with part rotation) when geometrical features such as run-out or concentricity must be measured.

Call 866-945-5742 or email: [email protected] for pricing

Dorsey Metrology BGD Bench Gages

BG Series bench gages are universal depth or flush pin gages used to check depths, lengths, face concentricity, or locations

Laser Micrometer

Ideal for non-contact precision diameter measurement, TIR, ovality, center position, and straightness.

TIR vs total runout

Total Indicator Reading (TIR) and total runout are both measurements used to assess the accuracy of a round object, but they have distinct differences:

1. **Total Indicator Reading (TIR):** This is a measure of the variation in a surface as it rotates around a datum axis. TIR is the difference between the highest and lowest points recorded by a dial indicator as the object is rotated. It represents the maximum deviation of the surface from a perfect circle. TIR is often used to check the concentricity and roundness of cylindrical parts.

2. **Total Runout:** This is a more comprehensive measurement that includes both the roundness and the axial alignment of a surface. Total runout measures the combined effect of variations in the surface profile and any axial displacement or tilt as the part rotates. It is assessed along the entire length of the surface, providing a single value that reflects all geometric deviations, including circularity, straightness, and coaxiality errors.

In summary, TIR focuses solely on the roundness in a single plane, while total runout encompasses roundness along the entire length of the surface, including any axial misalignment.

Call 866-9945-5742 or email: [email protected] for more information.

Spline Gages

Willrich Precision offers spline gages

Spline gages are designed according to the tolerances ‘actual’ and ‘effective’. From design to final inspection our design and manufacturing team will work with your team to meet and exceed your expectations.

Go and NOGO spline gages are available in Involute, straight-sided, angular sided, parallel sided and helical; all traceable to NIST. Involute and straight sided splines as well as serrations can be produced by hobbing, shaping, broaching, and rolling. Taper Master Plugs are available for use with GO or NOGO ring gages.

Both internal and external splines are cut using our CNC gear cutting machines. Hobbed splines can be made in lengths up to 50-60″.. Shorter splines can be cut up to 36″ in diameter; either internals with up to 9″ face length, or externals with longer lengths. For external, the exact length depends on the diameter of the spline and the configuration of the overall part.

Call 866-9945-5742 or email: [email protected] for pricing & more information.

JO-PLUG tapped hole location gage solid construction

JO-PLUG® tapped hole location gage.

The Precision JO-PLUG® true position locator remains the best gage on the market for determining true position, perpendicularity, and projected tolerance zone of threaded holes or tapped hole in conjunction with a CMM

Their solid thread form assures that the JO-PLUG® pitch diameter is calibrated, (front and back), using the universal three-wire method. ANSI/ASME Y14.5 M -1994, (R’99), Dimensioning and Tolerancing, states that “each tolerance of orientation and datum reference specified for a screw thread applies to the axis of the thread derived from the pitch cylinder.

The JO-PLUG® pitch diameter is coaxial to the cylinder portion of the gage, which projects a greater cylindrical tolerance zone than any other standard center-line locator on the market.

Call or email sizes for pricing Ph 866-945-5742 [email protected]

-or –

Fill out below Quick Quote Form for sizes needed.

Mahr MarCator 1087 Ri Wireless Digital Indicator MIN/MAX/TIR

Mahr Wireless Digital Indicator MarCator 1087 Ri. The multi-functional Digital Indicator with a combined analog and digital display as well as tolerance and dynamic measuring functions.

.

Mahr1087 R / 1087 ZR Digital Indicator analog display MIN/MAX/TIR

Mahr Digital Indicator MarCator 1087 R. The multi-functional Digital Indicator with a combined analog and digital display as well as tolerance and dynamic measuring functions. The 1087 ZR has .375″ stem and 4-48 contacts. The 1087 R has 8mm stem and M2.5 threads.

.