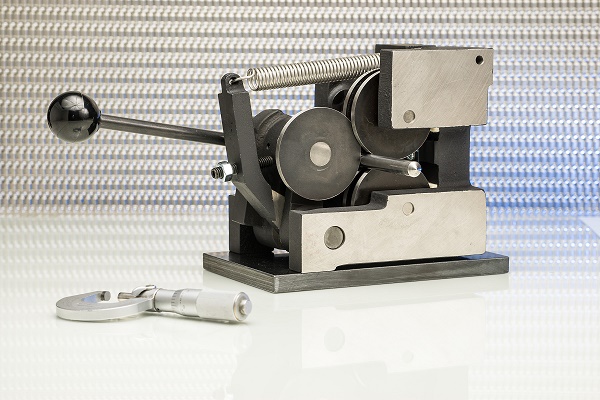

Universal Punch Model E Concentricity Gages Eccentric Checker Gage

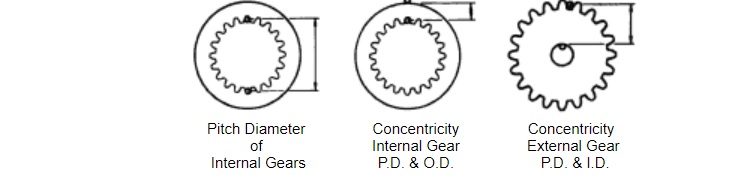

Universal Punch Model E Concentricity Gages. Concentricity Gages comprised of three major components. 1) select the gage model, 2) select the main rollers, 3) select and indicator and accessories. The concentricity gages are assembled into two classifications and directly traceable to NIST. Standard black gage is guaranteed to < or =4um accuracy. The Precision gold gage (-10 and -20 models) is guaranteed to < or = 8um accuracy (.00008″) accuracy

E-10 Standard Concentricity Gage Model ≤ 4µm (.00016) . Part diameters 1/8-1″

E-10P Precision Gold Concentricity Gage Model ≤ 2µm (.00008) Part diameters 1/8-1″

E-20 Standard Concentricity Gage Model ≤ 4µm (.00016) Part diameters 3/8″-2″

E-20P Precision Gold Concentricity Gage Model ≤ 2µm (.00008 )Part diameters 3/8″-2″

E-40 Standard Concentricity Gage Model ≤ 4µm (.00016) Part diameters 3/4-4″

E-40P Precision Gold Concentricity Gage Model ≤ 2µm (.00008) Part diameters 3/4-4″