The height gage is a theoretical extension of handheld caliper gage, with the only difference being that it rests on a heavy base, keeping the scale square. Today, height gages are designed not only to measure heights, but also distances, diameters and bolt circle patterns.

- Air Gages

- Bore gages

- Calipers

- Calibration Equipment

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

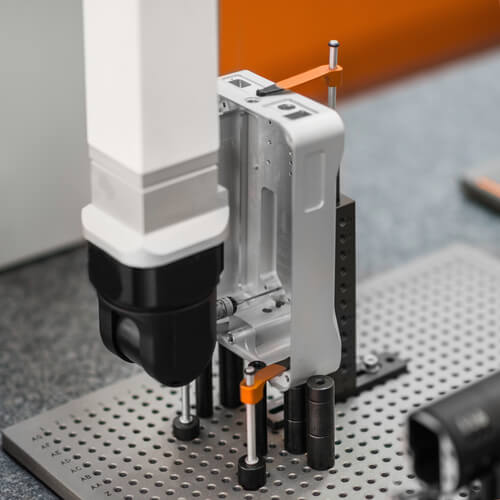

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- Height Gages

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Tips & Tricks

How To Handle Data Collection Tasks Like A Pro

The most operative technique to maintain control of manufacturing processes is to gather and analyze large amounts of dimensional data. Loss of time and energy is the last thing you want by producing defective parts. Efficiency is the key, and here’s some information to help you out in this regard.

Do You Know How To Set A Dial Bore Gage?

A vernier or dial bore gage directly measures a bore. It has 3 symmetrical anvils protruding from the gauge body that are linked to the micrometer mechanism. With the rotation of the knob, the anvils move in and out with respect to the measurement. To increase reliability and take the feel out of the device, the knob has a slipping mechanism.

Top Tips To Increasing Productivity On Your Shop-floor

When you own a business, one of the things that you will be concerned about is how you can increase your profits in time. Of course, you will definitely want to make sure that your products are as competitive as possible too. Well, you can achieve both these by simply boosting productivity most especially on your shop-floor. Investing in the right set of products will be just one of the things that will drive improvement when it comes to this vital concern. All the other things you can do are listed below.

When And How To Perform QC Inspection On Your Production Floor

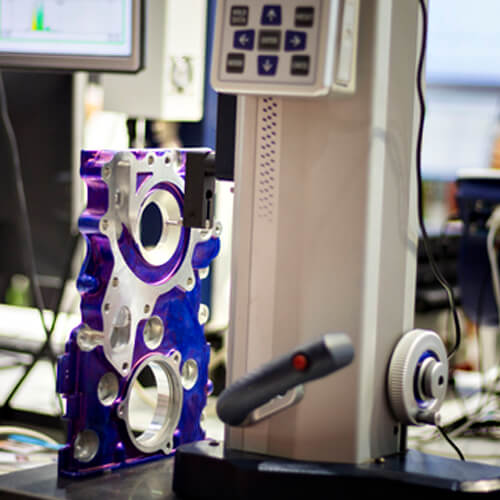

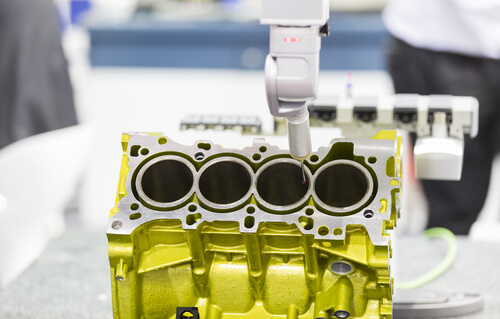

Production managers always know how important it is to make sure that their production processes are efficient. Some managers can measure respective parts directly on the shop-floor while others will send the parts to a lab where the CMM will do its part to thoroughly perform QC inspection. If you choose to do the inspection on your production floor as other production managers would then it pays to know how and when you can perform such.

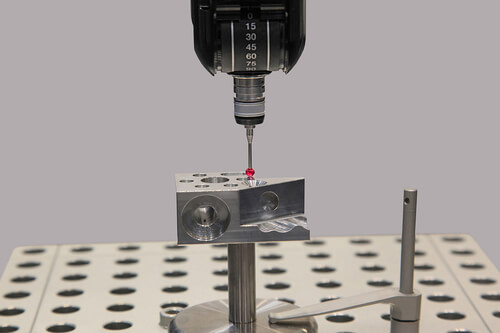

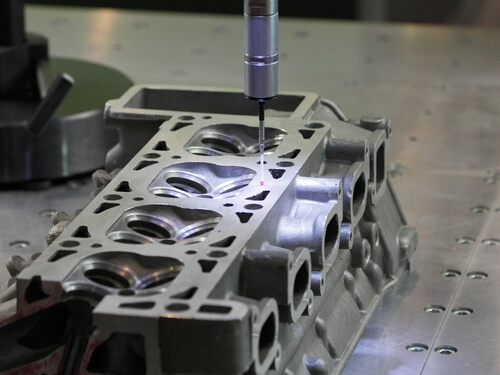

Top Tips For Inspecting CMM Touch Probe Accuracy

There’s always a way to know if the tool you’re using is doing the right job. Take an example of the screwdriver. If the screws are held firmly and can be screwed on and off successfully, then you know that the tool is working perfectly. But how do we know about CMM touch probe accuracy? How will you know if this high tech tool is functioning well and efficiently? A CMM probe is a complex device you place on the business end of your CMM. This device has lots of internal components that cannot be seen and are very delicate and susceptible to damage. These components can also easily go out of adjustment. In order to have a clear understanding of this, we’ll use the screwdriver analogy and think of the CMM probe as a screwdriver.

How To Save Time And Money When Using CMMs For Quality Control

The most delicate and important inspections are dedicated to coordinate measuring machines (CMMs). CMMs for quality control are a common choice for measuring complex, delicate parts. However, just like other aspects in manufacturing, there are significant costs and time one has to consider. Let’s have a closer look into the time and costs required to operate a CMM.

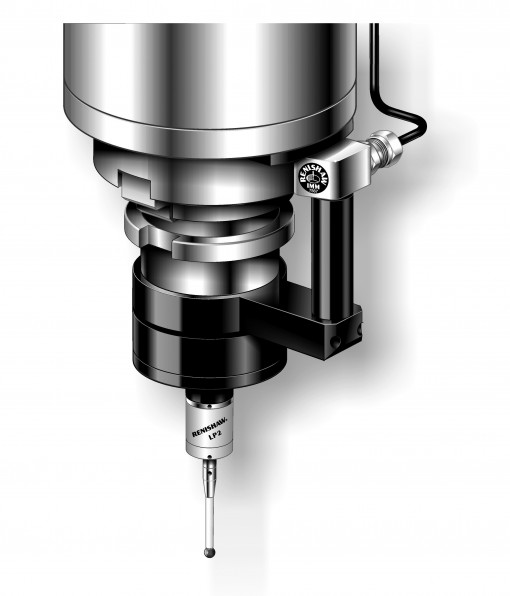

Do You Need Traditional CMM Or 3D Scanners?

For more than five decades, the coordinate measuring machine (CMM) has been the point of reference for accuracy in measuring compact objects. However, in the last two decades, a new technology emerged known as 3D laser scanning. The new technology arrived on the scene with more point capability, power, size and price value that are way better than traditional CMM technology. Companies have been relying on CMMs or 3D scanners to collect vital data and measurements on parts to ensure they are accurate and eliminate any inconsistencies.

Tackling The Issue Of Increasing Pressure On Tolerances

Parts manufactured by the aerospace and automotive industries are becoming more complex due to technology advancement. Tolerances that should keep up with metrology standards and quality control are now increasingly optimized and sophisticated. Moreover, customers need their dealers to ensure their own control in compliance. All these requirements put a lot of pressure on quality control teams and metrology. This post will explore how we can deal with constantly increasing pressure on tolerances. First of all, let’s take a look at the major reasons for evolution in quality control requirements in the aerospace and automotive industries.

How To Unload The Coordinate Measuring Machine

A coordinate measuring machine, frequently referred to as a CMM, is an integral player in the world of parts inspection and quality control procedures. In order for a product to meet with customer approval, it must first meet the requirements set forth by parts inspection and quality control. In metrology, a CMM is one of the most common pieces of equipment used during inspections. It is, in fact, very much in demand be at the metrology lab or the production floor.

Because the lab and the production floor are not located in the same place, it becomes necessary to transport and transfer the coordinate measuring machine. This is where you can run into problems. Many of the parts are large and the process of moving a CMM from one place to the other is arduous and long. What happens all too often is that bottleneck issues arise during transport, and that means a work slowdown. How can this be avoided?

How To Use A Dial Caliper

For automotive and machining applications, a tool called a dial caliper is frequently used as a reliable precision tool that is relatively easy to operate. It is capable of measuring parts to the thousandth. And though it is, as just stated, more or less easy to use, it is important that a dial caliper be used correctly and read accurately.

Keeping in mind that it is far easier to show someone how to use a dial caliper than it is to simply write it on a piece of paper and read it, not to mention far more beneficial for both parties, here is a guide on how to use a dial caliper.