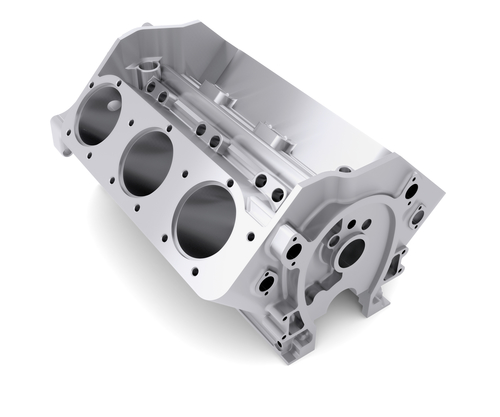

Bore gage is a collective term that refers to tools that are used to give very precise measurements of holes. There are many reasons why a manufacturing process would want to have a very precise measurement of holes. For example, the quality control process of a manufacturing plant might be very interested in measuring holes in a given part that is being produced, especially if that part is designed to fit into another part.

Any deviation from the set size would have costly implications for the manufacturer and therefore the quality control process has to use very precise tools to ensure that all the parts have the right size/shape of the hole. To this end, companies invest in bore gages and the choice of what type of gage to buy is determined by various factors that we are going to explore.

Consider The Manufacturing Environment

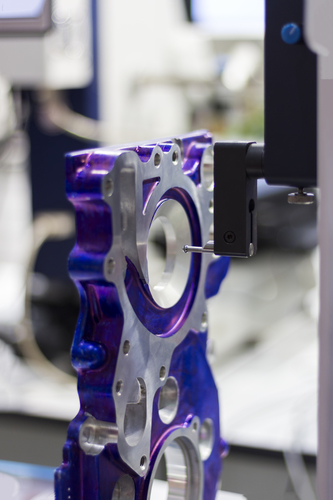

Various bore gages work in various environments and it helps to understand where exactly the bore gage that you want to buy is designed to work in. For example, if a manufacturing process will require the quality controller to move around randomly checking samples, it might make sense to get a bore gage that is easy to use and portable. Such a manufacturing process might discourage some of the non-contact gages that tend to be bulky and very expensive to maintain.

Consider Their Application

Various gages have varying capabilities. For example, some bore gages come with digital read-outs that allow for data collection. Other manufacturing processes don’t really care much for data collection as long as the bore gages can help them ensure that there is no variation in the parts being produced. With this in mind, it would be important to get a gage that has a digital read-out screen and a data collection port if data processing is important to your manufacturing process. If not, you might be ok with a simple bore gage which typically tends to be more durable and easy to use.

Level of Flexibility Required

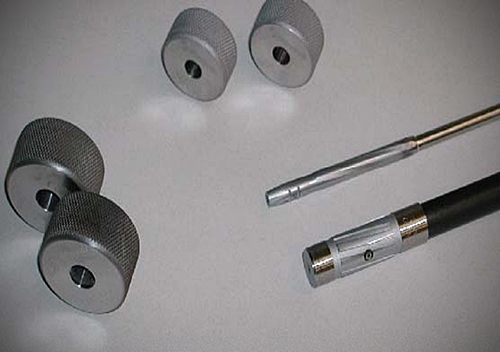

Some bore gages offer greater flexibility when it comes to calibration than others. A good example is the two-three point contact system that is calibrated to a reference master. The implication of this is that only the setting ring on the reference master needs to be calibrated and this offers a much easier and faster process of keeping the gages calibrated. For a manufacturing process that requires precision as well as fast calibration (such as a large and busy manufacturing plant), these kinds of gages might be more ideal.

Type Of Holes Involved

Holes come in different sizes, shapes and depths and all these factors play a part in determining the type of bore gage to be used. For example, air gages work well with holes that are tapered. Where they are located on the part and how accessible they are will also play a part in determining the type of gage you select. Air gages again are easier to use on holes that may be in positions that make it hard to use mechanical gages.

There are many factors to be considered when selecting a bore gage. Understanding your manufacturing process and what you want to measure with the bore gage are the first steps in determining what kind of bore gage to buy.