Surface roughness testers measure the surface characteristics of an object. This is important because the surface dynamics determine the usability of that product as well as factors such as durability. For example rougher surfaces are more likely to corrode and be subject to wear and tear than smoother surfaces. On the other hand, smoother surfaces are less likely to adhere to each other than rougher surfaces. During the manufacturing process, these instruments measure the surface characteristics of the manufactured part and compare it to a required ideal. Readings from surface roughness testers are often measured in units symbolized as Ra.

- Air Gages

- Bore gages

- Calipers

- Calibration Equipment

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- Height Gages

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

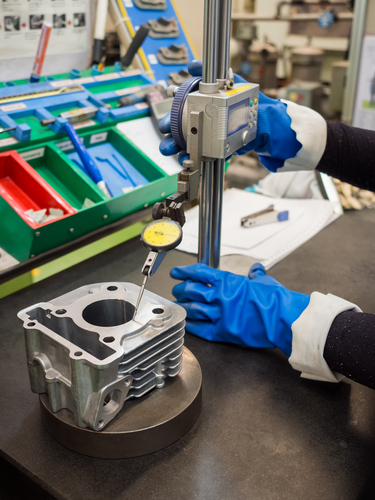

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Blog

Inspecting Small Holes Is A Job For Air Gages

Needles used to deliver fluids, fuel injection nozzles, and even aerosol cans are all examples of parts that use small holes for several reasons. Holes in nearly all of the aforementioned examples range from 0.1 mm to 1mm in diameter. To a layman, the holes may seem irrelevant. Experts will however tell you that in the medical field, that small holes used to deliver medicine or air to a patient can be the difference between life and death. This means that precision matters a lot as far as these holes are concerned. Let’s find out how to properly measure them:

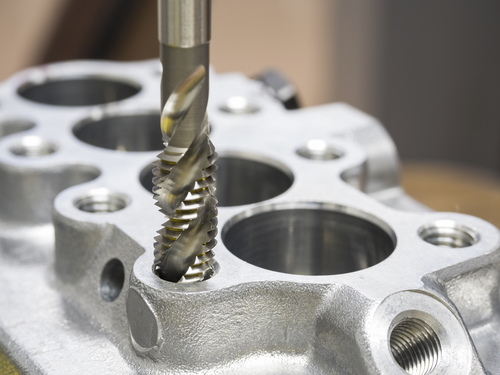

Getting Your Adjustable Bore Gage Settings Right From The Get-Go

Comparative instruments, such as an adjustable bore gage, can feature an electronic readout or dial that displays the direction and amount of variation in the test bore, from the nominal size. If you are using adjustable bore gages this way, you need to set the gage to the required nominal size, to which the bore is to be compared. There are various ways to set the bore gage to the nominal size. The methods explained below can provide a balance of versatility and reliability, precision, and speed. Read on to find out which setup method will work best for you:

How Should You Approach Measuring Internal Grooves?

Do you know that manufacturing a groove on a turned up part is actually easier than inspecting it? With this fact in mind, it is important to select the right measuring tools for internal grooves. Good gaging practice should always be maintained since grooves play a critical function especially for retainer rings and seal rings. There are different types of gages in the market that can measure grooves internally and externally. In this post, we will focus more on gages used to examine grooves internally. Let’s look at different types of gages used to measure internal grooves, their designs, and how they function.

Product Spotlight: Mitutoyo Digimatic Height Gage Series 570

Height gages allow an individual to measure the height of a workpiece. These measuring instruments often feature a slider with a measuring stylus. The stylus moves relative to a measuring scale that’s fixed onto a beam. Height gages are recommended to be used on granite surface plates or datum planes (that come with scribe part features). Today, you can find a wide variety of electronic and mechanical height gages on the market. They are indispensable instruments for quality control. In this post, you will find out more about an excellent height gage that can make measuring the heights of workpieces easier. Introducing the Mitutoyo Digimatic Height Gage Series 570. This product features an ABSOLUTE linear encoder that eliminates the need to repeatedly set the reference point at every power on. In other words, you will be able to avoid overspeed errors!

Measuring With A Depth Gage

Depth gages typically consist of short-range indicating devices mounted through a plate or a reference bar. They are among the simplest indicator gages that are used in thousands of critical applications. Depth gages are used to measure the depth of recesses, holes, slots, counter bores, cavities, and other component features. Depending on the specific application, they are available in various configurations.

How To Simplify Gaging Processes

At the most basic level, manual gages are designed to make it easier to stage and gage a workpiece, ensure the best possible performance for the measuring task at hand, and reduce operator error. With this type of fixturing, the technician does not need to expend a significant amount of effort and time to complete the task. Today’s manufacturing operations are fast-paced. Those operations are also based on short runs of precision parts and flexibility. That is why using a gaging system that matches the way components are made is highly recommended. Here are further ways to simply gaging processes:

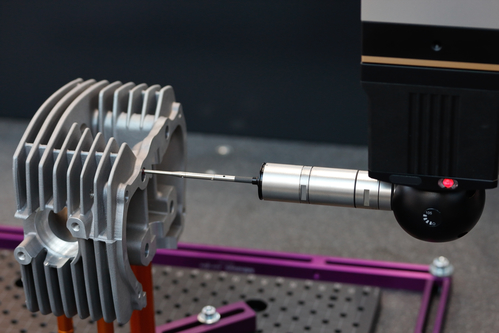

How Should Manufacturers Approach Buying CMMs?

The Coordinate Measuring Machine, otherwise referred to as the CMM is a familiar tool in manufacturing facilities. It stands out as one of the most effective and reliable tools used in quality control. Used for three dimensional measurement and verification, CMMs come in different designs and of course brands. This makes it hard for a manufacturer with little or no knowledge on CMMs to buy one. There are however, factors that can make the whole buying process easy. Such factors include:

Gaging For SPC Made Simple

Much has been said and written about statistical process control, commonly referred to as SPC. Shop owners seem to keep off the process, citing reasons such as how expensive SPC gaging equipment are or how small their facilities are. These two reasons can best be termed as misconceptions. SPC is not as complicated as most people think. Secondly, you do not need complex computerized systems and costly software to get into SPC. You should therefore benefit from gaging for SPC, as much as your competitors do. But before that, here is how to simplify the whole gaging process.

Why It’s Important To Facilitate Gage Calibration Regularly

When it comes to metrology, nothing matters more than accuracy. That’s why it is important to invest in high-quality calibration equipment if you are in the metrology industry. But even then, regular calibration is vital because even with the most advanced equipment, you risk inaccuracy anytime you ignore regular calibration. What then follows are losses, botched expenses and costly expenses. To fully appreciate the importance of regular gage calibration, one needs to first understand what calibration is and how the whole process works.

How Digital Micrometers Help You Achieve Maximum Precision

Small, sleek, light, and accurate – these are some ways to describe the digital micrometer. It gets better with the fact that you can slip it into your tool belt or shirt pocket. Alongside calipers, the digital micrometer is the most popular, effective and reliable measurement and inspection tool. This is despite the proliferation of new and technically advanced equipment that at some point threatened to make the digital micrometer moot in modern manufacturing. So, just how effective are digital micrometers? What makes it special?

Top Tips To Using Adjustable Snap Gages

Snap gages are basically go/no go gages that measure outside diameters. Their appearance is similar to micrometers. A snap gage also features anvils that can be found on a micrometer too. You should keep in mind that snap gages come in an array of sizes and shapes. There can be types A, C, and U, and the gages may come with dial or digital indicators. Apart from measuring outside diameters, snap gages can be used for measuring widths and groove diameters. In this post, we will focus on one of the main variations of snap gages – adjustable snap gages. You will learn how to master this extremely useful gage.

Understanding The Evolution Of Air Gaging

Air gaging is known as a contact-free form of gaging. It is a stellar option for measuring extremely thin-walled parts of soft materials. Other common applications include measuring straightness, center-distances, squareness, tapers, average diameters, and more. Air gaging is accurate, fast, and readily used in a wide range of production environments. In addition, its tooling has largely remained the same over the years, i.e. precision orifices with steel rings or tubes that set up a distance/pressure curve when in use. Here is a further look at how air gaging has evolved over the years.

Understanding The Effectiveness Of Air Gages In Metrology

Air gages stand out as one of the most effective measuring devices ever made. The device has come a long way, with its history dating back to 1919 when it was invented. The rest as they say, is history. It simply transformed metrology for the better. It developed through the years, with innovations making the device better and better. It is worth noting though, that the air gages used today do not differ so much from the first one invented in 1919. The concept is still the same. So, why in the first place is the air gage important?

The Right Height Gage For The Right Application Makes All The Difference

One of the general-purpose tools that technicians use to measure precision parts is a height gage. These gages can measure the roundness, roughness, waviness, diameter, length, and thickness of a wide range of objects and materials. Today, almost 90 percent of height gages are utilized for surface plate work, including surface metrology (for analysis of features and textures) and surface analysis.