The ability of a material to resist permanent indentation is known as hardness. It is an empirical test, rather than material property. In order to define different hardness values for the same piece of material, there are several types of hardness tests. The outcome of each test should have a label identifying the method used, as it is dependent on it. There is no intrinsic significance of hardness value or number, hence it cannot be used directly like tensile test value. The value is only useful for comparing different treatments or materials.

- Air Gages

- Bore gages

- Calipers

- Calibration Equipment

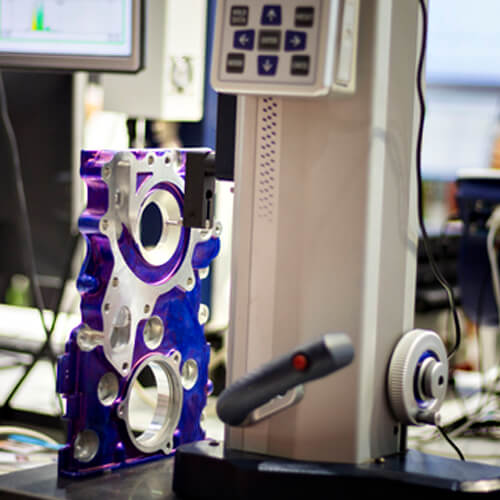

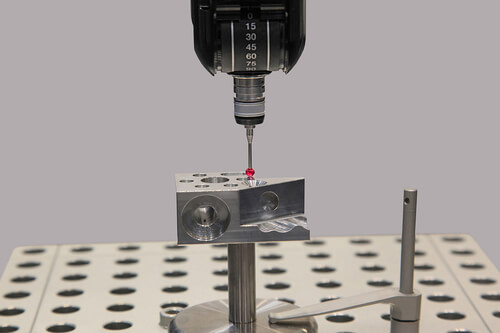

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- Height Gages

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS

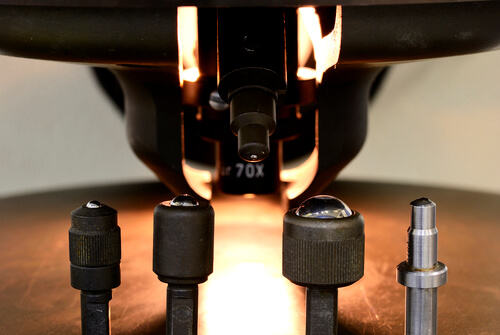

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

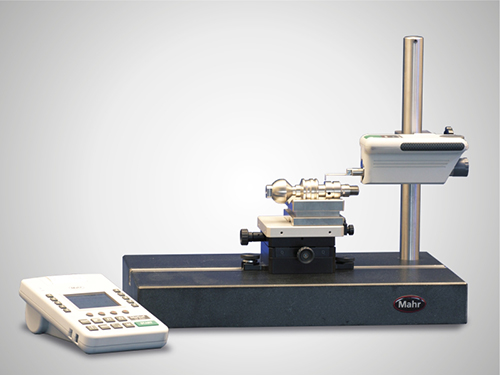

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Blog

Important Questions To Ask When Searching For A Suitable Metrology Service Provider

In the United States, there is a wide range of metrology service providers. Each company claims to be the best in the industry promising potential customers premium services. How can one tell that a metrology service provider is qualified enough for their specific needs? Before you sign off with a metrology company, there are several questions you need to ask. The questions will help you to get to the core issues that may otherwise lead to problems with your precision measurement projects.

Understanding Alignment, Balancing, And Vibration In The World Of Metrology

The world of industrial maintenance is hectic, demanding and intensive. Even when working in the world of metrology, it can be hard to understand the differences between alignment, balancing and vibration. In this post, we will provide you an in-depth overview of each term and what role they play to ensure the health of your equipment.

Product Spotlight: Starrett VB400 Bench Top Vertical Optical Comparator

The VB400 bench top vertical optical comparators are versatile measuring systems ideal for the 2D measurements of flexible and flat parts such as plastic, gaskets and sheet metal components. The VB400 optical comparator has a 400 mm diameter screen, you will be able to make large part enlargements using various optional magnification lenses. This is a standard feature for all VB400 optical comparators.

Direct And Indirect Torque Measurement Techniques In Drive Train Technology

Torque is a type of force that tends to cause rotation. It is one of the most important mechanical quantities in many industrial applications. Precise measurement of the torque on rotating sections, placing high demand on test bench users and manufacturers. There are a couple of ways to determine torque:

Why You Should Start Using CT Scanners

CT scanning technology can inspect the interior structure of the injection forged, molded or cast parts made from composites, polymers, plastic and metal products, without causing any damage to the objects. Seeing through a solid object was once a fantasy, but the technology of computed tomography imaging has made it possible. It is now being used in various industrial metrology settings for packaging integrity and product evaluation.

Product Spotlight: Vision Engineering SX45 Industrial Stereo Zoom Microscope

The typical applications of industrial stereo zoom microscopes include small parts inspection, quality control, manufacturing processes, soldering jobs, and more. If you are working with a sample and it fits in the palm of your hand, a standard stereo microscope will suffice. The aforementioned can be used with a lighted post stand. If you require a greater working area to handle larger objects, you should opt for an industrial stereo microscope that comes with an articulated arm stand. If your job requires you to frequently slide the body of the microscope out of the way, you should consider stereo boom stand microscopes for your needs.

Top Tips To Getting More Accurate Height Gage Measurements

The height gage is a theoretical extension of handheld caliper gage, with the only difference being that it rests on a heavy base, keeping the scale square. Today, height gages are designed not only to measure heights, but also distances, diameters and bolt circle patterns.

Product Spotlight: MarSurf M 400 C Surface Roughness Tester

Surface roughness is an important parameter when it comes to determining a surface’s suitability for certain applications. Rough surfaces usually wear out at a faster rate than smoother surfaces. The aforementioned is also more vulnerable to cracks and corrosion. However, rough surfaces can aid in adhesion. To uncover these details, a roughness tester is utilized so that the parts specialist can accurately and quickly determine the surface roughness or surface texture of a material. You can use a roughness tester to get roughness value (Ra) and roughness depth (Rz) in microns (µm) or micrometers.

Should You Purchase A Video Inspection System Or Microscope?

It can be a daunting task to choose the right inspection system for your application. Three types of inspection systems are generally employed for industrial applications. Let us a take a look at each one of them, along with their merits and demerits.

Product Spotlight: FP-4USB FlexPort Gage Interface

Gage interfaces are designed to help individuals transfer data directly into MS Excel or into an SPC software. At Willrich Precision, we understand that it can be a challenging or confusing task in getting the correct gage interface equipment for your needs. That’s why we offer an array of gage interface boxes and gage interface cables to all our valued clients. If you are looking to get the FP-4USB FlexPort Gage Interface, you have come to the right place. Our FlexPort Gage Interface is easy to set up and use. You will be able to control the flow of information to your PCs, and make data collection an error-free and simplified process.

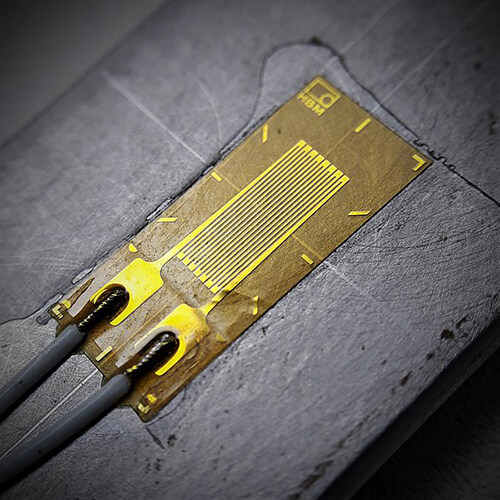

What You Need To Know About Strain Measurement Errors

Strain measurement is capable of resolving one PPM (one part in a million) or more. This is because of the exacting controls and standards under which each strain gage is manufactured. Some of the principal measurement errors arise from the manner in which the strain gage sensor is installed and measurement is taken. Let us take a look at some of these.

How To Handle Data Collection Tasks Like A Pro

The most operative technique to maintain control of manufacturing processes is to gather and analyze large amounts of dimensional data. Loss of time and energy is the last thing you want by producing defective parts. Efficiency is the key, and here’s some information to help you out in this regard.

Essential Tools To Have For CNC Machine Shop Owners

The science of measurement is known as metrology and the application of its principles plays a pivotal role throughout production process in CNC machining. This is done to make sure that each and every part is machined to the right shape and size. Measuring dimensions of a CNC machine part with tight tolerances can be difficult. Depending on the quality, quantity and the type of work they do, there are distinct set of metrology tools in every CNC machine shop. Here are a few you should have, if you are an owner.

Do You Know How To Set A Dial Bore Gage?

A vernier or dial bore gage directly measures a bore. It has 3 symmetrical anvils protruding from the gauge body that are linked to the micrometer mechanism. With the rotation of the knob, the anvils move in and out with respect to the measurement. To increase reliability and take the feel out of the device, the knob has a slipping mechanism.