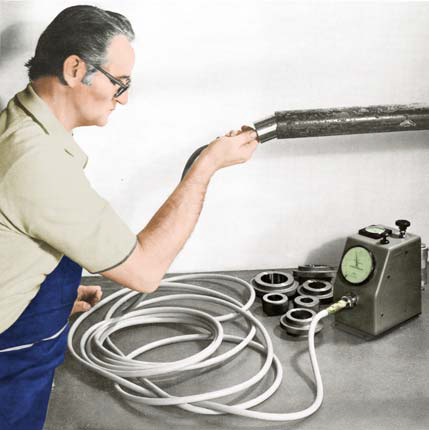

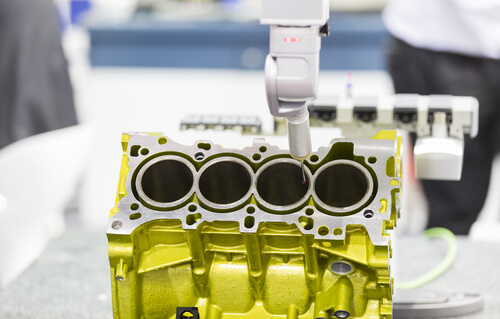

Air gaging is a powerful metrology method and first started ensuring quality in the late 1910s. Early versions of such systems were regulated by bubbling air via a level of water within a cylinder, in which air was also passed. The technique utilizes compressed air to measure changes in flow rates and pressure. Oftentimes, air gages are employed in tests where the distances between a workpiece and the precision orifices needed to be measured.

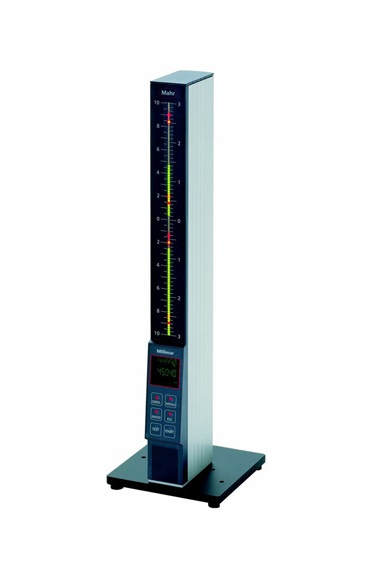

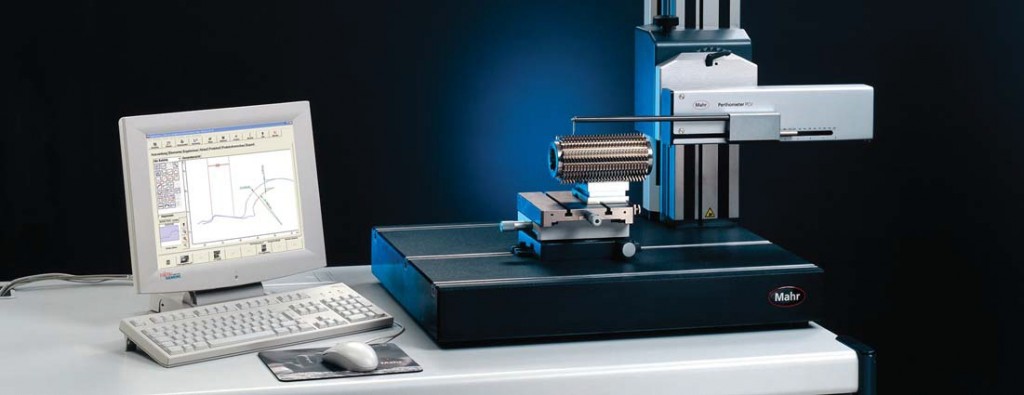

Air gages have the ability to measure small tolerances because of the reliability and magnification they can provide. A resolution as small as 0.00002 inch can be achieved! If you need to measure extremely thin-walled parts for soft materials, air gaging is the noncontact solution you can count on. If you are looking for an air column amplifier, you should consider the Mahr Federal S1840 Air Column Amplifier. Let’s find out more about this amazing product in this product spotlight!