With all of the types of height gages available, and with each of their matching applications, it might be hard to decide which one is the most appropriate for you. Which gage will meet your needs? The following will hopefully help you distinguish between not only the different types of height gages but the various purposes for which they were designed.

- Air Gages

- Bore gages

- Calipers

- Calibration Equipment

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- Height Gages

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Tips & Tricks

What You Should Know About Digital Height Gages

Digital height gages sometimes get a bad rap. People refer to them as nothing more than a giant-sized caliper based, apparently, on its range of motion. But there is so much more to a digital height gage than that. It is, without a doubt, a benchtop gaging measurement system of the most sophisticated and accurate nature. Not only that, the multitude of tasks that it can perform reliably and quickly are impressive.

How To Measure Concentricity

As evidenced by the title, today we’re going to take a look at how to measure concentricity, what it is, and other related areas. First of all, let’s start off with a description.

Top Tips To Achieving Faster Precision Measuring Processes

If you need faster precision measuring or you are looking to speed up the process you already use. There are ways you can do this. Some of these include:

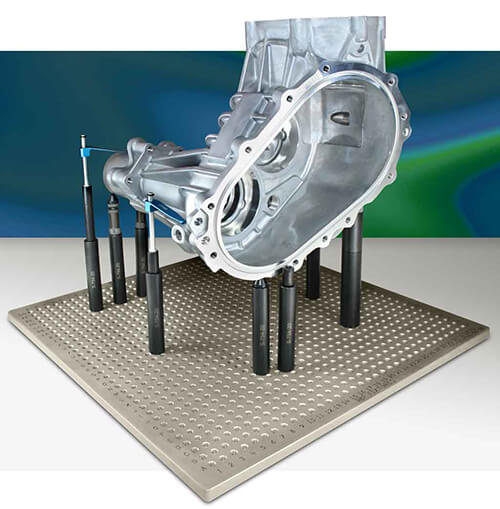

Top Tips To Choosing The Most Effective Workholding Solution

To ensure you capture accurate data and calculations, it is essential that the workholding solution you use is up to the job. Some inferior or cheaper workholding equipment may not be able to withstand the pressure put on them during manufacturing at high speeds. There are many different solutions available, including a bespoke or customized workholder.

Get A Grip On Hand-Held Measuring Instrument Errors

The main function of a force gage is quite simply to measure any force in a push-pull test. These tests are generally carried out by the engineering field, laboratories or the design field for specific instruments. There are digital and mechanical force gages available and although either hand-held measuring instrument are designed to give an accurate reading, there are times when their readings may show minor errors.

Learn The Basics Of Toolmakers Microscopes

What are toolmakers microscopes? For starters, they are multi-functional devices that can be found in a wide range of manufacturing facilities involved in the manufacturing of tools, electronics, and machines. They are also easily identifiable by their robust base and being capable of facilitating a great array of measurement and observation procedures. If you are new to toolmakers microscopes, read on to find out more about the basics of this stellar equipment!

How To Minimize Vibration Tendencies In Machining Procedures

Today, a great array of internal precision machining operations is now facilitated via diamond or hard-metal tipped cutting tools. In addition, tool holders are available in various forms to suit the specific machining requirements. Now, factors such as the service lifespan of the cutting tool, the dimensional accuracy of the workpiece, and surface quality are affected by the material properties of the toolholder. If you do not get them right and need to facilitate a deep-hole machining procedure, you may encounter excessive vibration issues in the tool shaft. This can happen if there is a high degree of overhang; you will get that undesirable chattering. Let’s find out more about vibrations and how you can minimize them.

The Do’s And Don’ts Of Dial Indicator Usage

One of the most popular reasons for using a dial indicator is ease of use. Sometimes it is not necessary to take very precise measurements, but you may still need to know that the measurement of something is within the parameters you expect. This is where a dial indicator excels. If you do not need use extensive or very accurate interpreting skills, then the dial indicator is the perfect tool for you and as it is very cheap to acquire, it is cost-effective too.

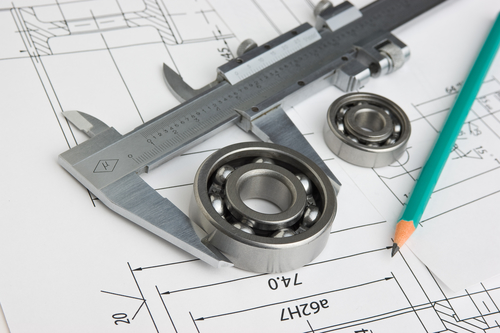

Master The Use Of Calipers

Calipers have been used for hundreds of years in one form or another. They are used to take basic measurements, and they are the one tool that many self-respecting carpenters cannot do without. They are also used by engineering firms to help with inspection. Today, there are a range of different types of calipers. These are: wireless, Vernier, electronic and digital. Calipers give a precise measurement but mastering them is an essential skill that needs to be acquired to ensure you get the most accurate measurement.

How Are Liquid-Filled Gages Usually Vented?

Liquid-filled gages are the most preferred choices for process environments requiring high physical stress because they are capable of protecting those environments from shock and vibration. Installing one requires a lot of careful though and consideration, on top of which, is making sure that the gauge is filled with the appropriate amount of liquid to be used for that particular application. Take note that silicone and glycerin should not be used when filling pressure gages where there are strong oxidizing agents. Additionally, venting these gages will relieve internal case pressure before use. The question is how are they usually vented?

6 Factors You Should Consider When Calibrating Pressure Gages

The process industry uses pressure gauges very often and just like any other measurement devices, they need to be calibrated at regular intervals to remain accurate. Measurement devices tend to drift over time and unless they are calibrated at certain intervals, they lose their accuracy.

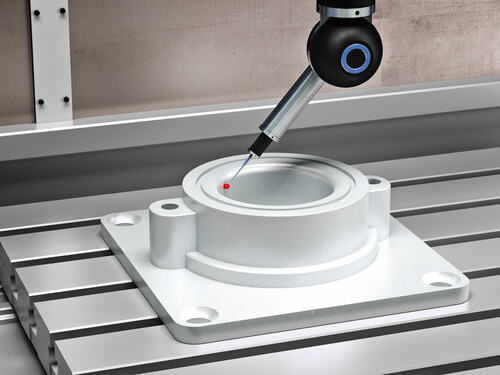

Tips For Unloading Your Coordinate Measuring Machines

Coordinate measuring machines, also known as CMMs, are crucial pieces of equipment in the world of parts inspection and quality control. These are commonly used in carrying out inspections in the metrology industry and are very much needed in both the production floor and metrology lab. Since these machines are very popular, they take up to much work load considering the fact that they are not the fastest moving machines within the lab. The good news is you can easily unload these machines so that you can speed up the manufacturing process. Here is what you should do.

Do You Know How To Calibrate A Roundness System?

There is a thin line between calculus and the calibration of roundness measuring system – not so many people understand them. Even the few ones who do end up making mistakes most of the time. Take the word ‘calibrate’ for example. Most precision experts use it all the time in the world of roundness. The word means to determine what one has as compared to a given proper value. The right word to use instead of calibrate is to ‘adjust’ or ‘correct’. So how is calibrating a roundness system done?

Important Questions To Ask When Searching For A Suitable Metrology Service Provider

In the United States, there is a wide range of metrology service providers. Each company claims to be the best in the industry promising potential customers premium services. How can one tell that a metrology service provider is qualified enough for their specific needs? Before you sign off with a metrology company, there are several questions you need to ask. The questions will help you to get to the core issues that may otherwise lead to problems with your precision measurement projects.