Hexagon Structured Light Scanning Systems StereoScan Neo

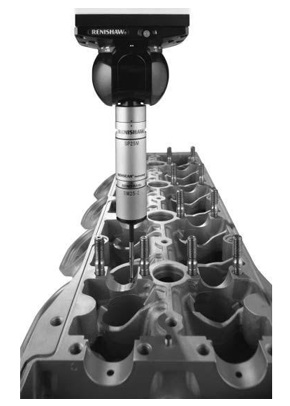

Hexagon Metrology Advanced structured light scanning Structured light scanning is a well-established and highly reliable technology for three-dimensional surface acquisition. Even complex surface geometries are captured swiftly and at a high level of resolution and accuracy with this advanced non-contact optical 3D scanning technique. Owing to their exceptional mechanical and thermal stability, Hexagon’s range of structured light scanner systems can be employed across a multifaceted array of applications. Extremely sturdy by design, these two-camera systems are renowned for their extraordinary combination of ruggedness and precision, allowing them to meet the challenges of modern metrology from the most sterile quality room to the dustiest shop floor. Hexagon structured light scanning technology works with the dedicated OptoCat software platform, designed to quickly transform high-quality measurement information into precise digital mesh data, as well as directly within third-party metrology software through plug-ins based on the SLS SDK. High-speed, high-resolution, high-accuracy measurement! Ideal for reverse engineering.

Call 866-945-5742 or email: [email protected] for more information or to arrange a demonstration.

Key advantages

• Ideal introduction to high-end 3D

metrology.

• Smart Data Capture technology allows for fast acquisition and variable resolution.

• Fast and easy change of measuring fields.

• Upgradeable modular system configuration.

• Scanning of glossy and dark surfaces without pre-treatment.

• Mechanical and thermal stability.

• Compact and low-weight design.

• Handheld probe option.

• Combinable with photogrammetry systems.

• Accessories such as turntable and turn-tilt units allow for semi-automated scanning.