Liquid-filled gages are the most preferred choices for process environments requiring high physical stress because they are capable of protecting those environments from shock and vibration. Installing one requires a lot of careful though and consideration, on top of which, is making sure that the gauge is filled with the appropriate amount of liquid to be used for that particular application. Take note that silicone and glycerin should not be used when filling pressure gages where there are strong oxidizing agents. Additionally, venting these gages will relieve internal case pressure before use. The question is how are they usually vented?

- Air Gages

- Bore gages

- Calipers

- Calibration Equipment

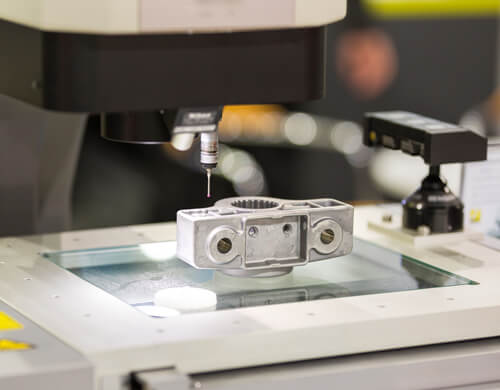

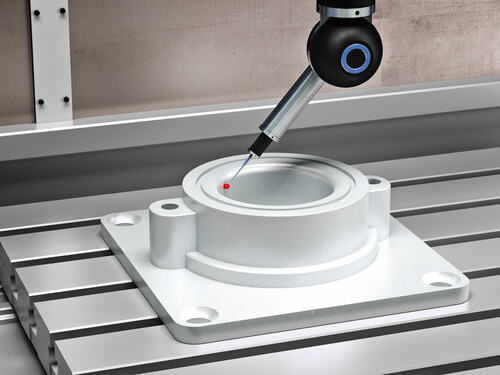

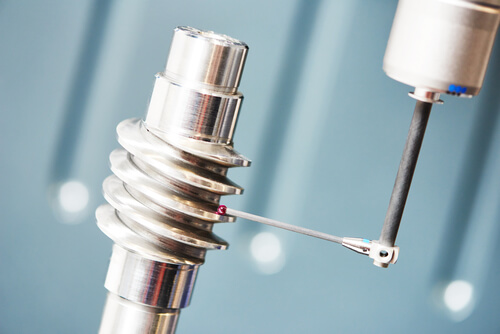

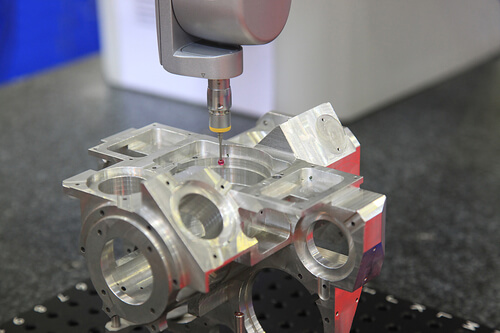

- CMMs Coordinate Measuring

- CMM Sensors, Probes & Styli

- Computed Tomography – CT Scanners

- Concentricity Gages

- Contour Measurement

- CUSTOM GAGES & FIXTURING

- CYLINDRICAL GO / NO GO / MASTERS

- Data Collection & SPC

- Depth Gages

- Fixtures & Part Holding CMM, Vision, Optical

- Force & Torque Gages

- Gage Blocks

- Gear & Spine Measurement

- GRANITE SURFACE PLATES, SQUARES & PARRALLELS

- HARDNESS TESTERS

- Height Gages

- HEX, HEXALOBE GAGES & SQUARE GAGES

- ID / OD GAGES & SNAP GAGES

- Indicators & Comparator Stands

- Laser Micrometers

- Layout and Shopfloor

- MICROMETERS

- MICROSCOPES & BORESCOPES

- Optical Comparators, Overlay Charts and Readouts

- Robotics and Automation

- ROUNDNESS & FORM

- SHAFT MEASUREMENT

- Structured Light 3D Analysis

- Surface Roughness Testers

- Thread Gages

- Video Measuring Machines

Blog

6 Factors You Should Consider When Calibrating Pressure Gages

The process industry uses pressure gauges very often and just like any other measurement devices, they need to be calibrated at regular intervals to remain accurate. Measurement devices tend to drift over time and unless they are calibrated at certain intervals, they lose their accuracy.

Data Integrity Pitfalls In Calibration Procedures

Data integrity is the assurance of the accuracy, maintenance of and consistency of the data. The concept of data integrity has been applied for many years. However, it has become more acute recently since auditors are paying more attention to data integrity than before. The FDA, EMA and other regulatory bodies have also set new regulation guidelines that need to be adhered to.

Product Spotlight: Shimpo DT-365 & DT-365E High Intensity LED Portable Stroboscope

If you are looking for one of the brightest and most versatile stroboscopes, then you can do no better than this! Introducing the Shimpo DT-365 & DT-365E high intensity LED portable stroboscope. A stroboscope is used to study rotating or oscillating objects. Since it was discovered in 1832 by Joseph Plateau, it has come a long way and its uses have increased. Stroboscopes are important as a scientific tool to study the stress placed on machine in motion, amongst other things. As the LED light in a stroboscope is very bright, it is able to give the effect of an abject “freezing or moving slowly.

Understanding The Roughness Parameter Called “Max”

A quick glance at a finished surface will make you think it looks perfect. However, imperfections are bound to be there, and they may come in the form of valleys and hills, varying in both spacing and height. Roughness as that is called, exists in the form of a succession of minute irregularities. This may be caused by its own finishing process, such as the utilization of a single point tool. Surface roughness tends to be both directional and uniformly spaced. If surface roughness was a result of cylindrical or straight grinding, the roughness of the surface tends to be irregularly spaced.

Tips For Unloading Your Coordinate Measuring Machines

Coordinate measuring machines, also known as CMMs, are crucial pieces of equipment in the world of parts inspection and quality control. These are commonly used in carrying out inspections in the metrology industry and are very much needed in both the production floor and metrology lab. Since these machines are very popular, they take up to much work load considering the fact that they are not the fastest moving machines within the lab. The good news is you can easily unload these machines so that you can speed up the manufacturing process. Here is what you should do.

Product Spotlight: Mahr PLM 1000-E Precision Length Measuring Machine

The Mahr PLM 1000-E Precision Length Measuring Machine is able to offer accurate internal or external readings for a variety of objects. These are commonly metallic in nature such as: ring gauges, calipers, plug gauges, or any other kinds of gauges, as well as pins. It is also used in the calibration of items such as, dial indicators, snap gages, gear gages and internal micrometers.

Do You Know How To Calibrate A Roundness System?

There is a thin line between calculus and the calibration of roundness measuring system – not so many people understand them. Even the few ones who do end up making mistakes most of the time. Take the word ‘calibrate’ for example. Most precision experts use it all the time in the world of roundness. The word means to determine what one has as compared to a given proper value. The right word to use instead of calibrate is to ‘adjust’ or ‘correct’. So how is calibrating a roundness system done?

Product Spotlight: Renishaw Equator

The Renishaw Equator has transformed the metrology industry. This system is a plug-in and play system, and it has the ability to save your company time and money in the manufacture of precision metallic parts. The Renishaw Equator is able to save money by providing 100% inspection for your part by creating a 3D model image of the required part before printing. This allows for a reduction in wastage on production costs, as it will be perfectly replicated the first time, every time. In addition, the system is so easy to use that you will not need to spend a fortune on specialist staff training, as it comes with comprehensive instructions as well as video help. This really is a revolution in the metal replication industry. This one-time investment will pay for itself in reducing your overall operating costs and the quick duplication of the automated process, will ensure your productivity is increased.

Understanding The Importance Of Metrology In Our Daily Lives

Accessing knowledge can never be possible without a number as well as a standard of measurement which produces the said number. It gets more interesting with the fact that both the number and the measurement cannot exist without units. This is more or less the role of metrology. It stands out not only as an individual discipline of physical sciences but also the base of daily activities. It is in fact, safe to say that people use metrology daily without realizing it. In light of this, measurement is therefore, an economic, social and scientific necessity. Understanding this makes it easy for one to understand the importance of metrology in our daily lives.

What You Need To Know About Coating Thickness Gages

Also known by the name of paint meter, a coating thickness gauge is used for the measurement of dry film thickness. This parameter is possibly the most important one in a wide range of industrial applications, since it has a significant impact on cost, quality and coating process. These measurements can be employed to estimate the life expectancy of coating, the performance and appearance of product, and to guarantee agreement with a host of industry standards.

Product Spotlight: Starrett 258 Series Digi-Chek II Height Gages

Height gages are devices used to measure the distance from a reference surface. These devices are exceptionally accurate and they can measure surface plates and even intricate features of a part. There are several types of height gages and they include electronic height gages, dial height gages, vernier height gages and more. These devices play a very important role to ensure quality control.

Why You Should Update Your Calibration Systems

A majority of companies in the process industries are looking to update its calibration systems and process. There are plenty of reasons why there’s a need of upgrading a calibration system. Updating the process basically implies work procedures and systems for managing, documenting and performing calibration of process instruments. There is an obvious reason behind any change, and most probably, it is the issues or challenges in the present way of doing things. Let us take a deeper insight into some of the common problems that may incite process changes.

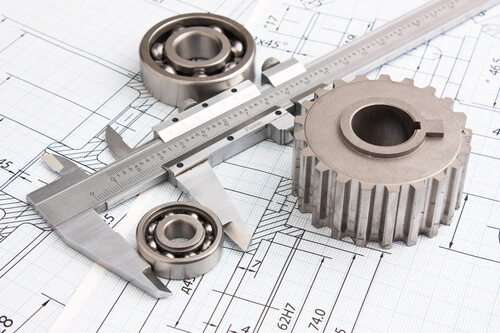

Little Known Facts About Precision Measurement Tools

It is certainly surprising that some technicians know little about the precision measurement tools they use on a daily basis. In some cases, there may be a lack of resources to give accurate descriptions about what these tools are and what they are really designed for. This lack of knowledge may lead those technicians to buy and use the wrong tools for specific jobs.

Product Spotlight: Dyer Gage 651 Series Electronic Groove Gages

Like any other precision measurement tools, groove gages have undergone a tremendous change from mechanical scales to being digital marvels. Today, groove gages are applied in hundreds of critical applications to measure the depth of recesses, slots and centerbores, as well as locations and heights of some features. They are very common in the tool and die industry.